Continuous collapsing type detachment method for multi-span elevated bridge

A technology for viaducts and bridges, applied in the directions of bridges, bridge maintenance, bridge reinforcement, etc., can solve problems such as high cost and cumbersome process, and achieve the effects of environmental protection, clear force, and strong technical operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

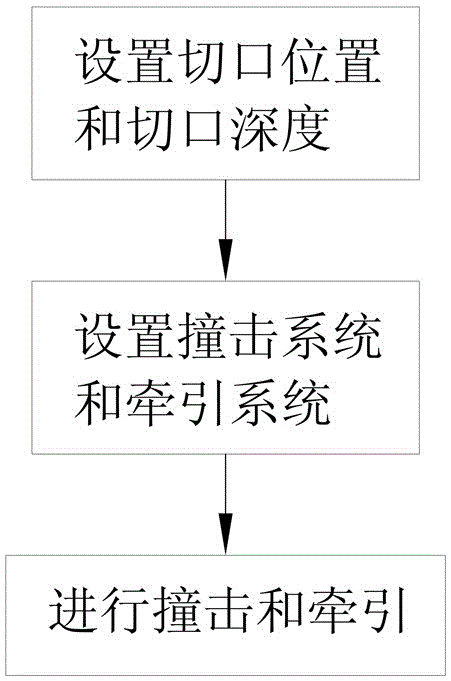

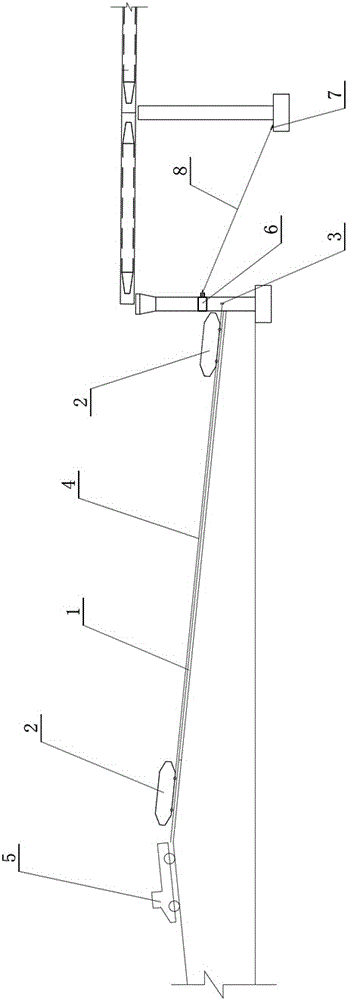

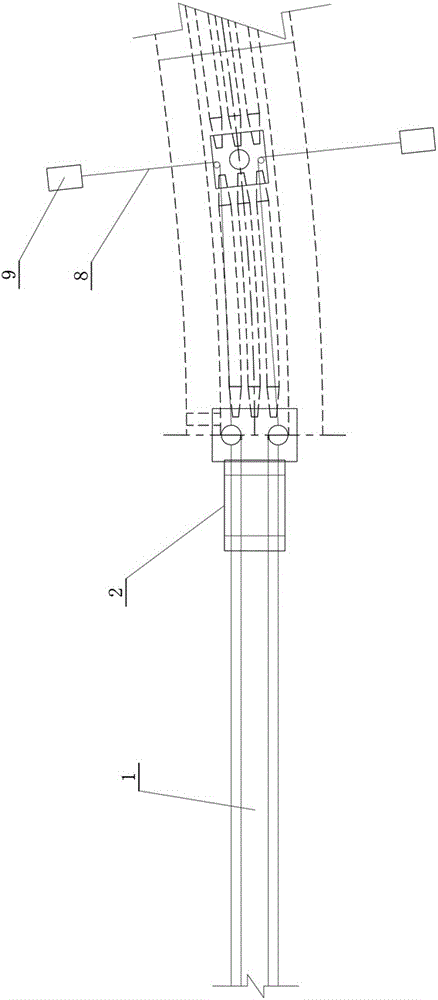

[0023] Figure 1 to Figure 3 A kind of embodiment of the continuous dumping type demolition method of multi-span viaduct bridge of the present invention is shown, comprising the following steps:

[0024] S1: Set the notch position and notch depth: select the notch position on the beam body, the distance between the side pier and the adjacent notch position and the distance between the two adjacent notch positions is greater than the distance between the two adjacent piers ; Cut the beam body along the notch position, and the notch depth should keep the beam body stable under the action of self-weight, construction load and live load;

[0025] S2: Set the impact system and traction system: set the impact system at one side pier of the bridge, and set the traction system along the impact direction on the side pier;

[0026] S3: Perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com