Capillary tube phase change insulation part, building wall comprising same and building

A capillary and thermal insulation technology, which is used in building construction, thermal insulation, construction and other directions to achieve the effect of strong heat exchange.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0024] The specific implementation manners of the embodiments of the present invention will be described below in conjunction with the accompanying drawings.

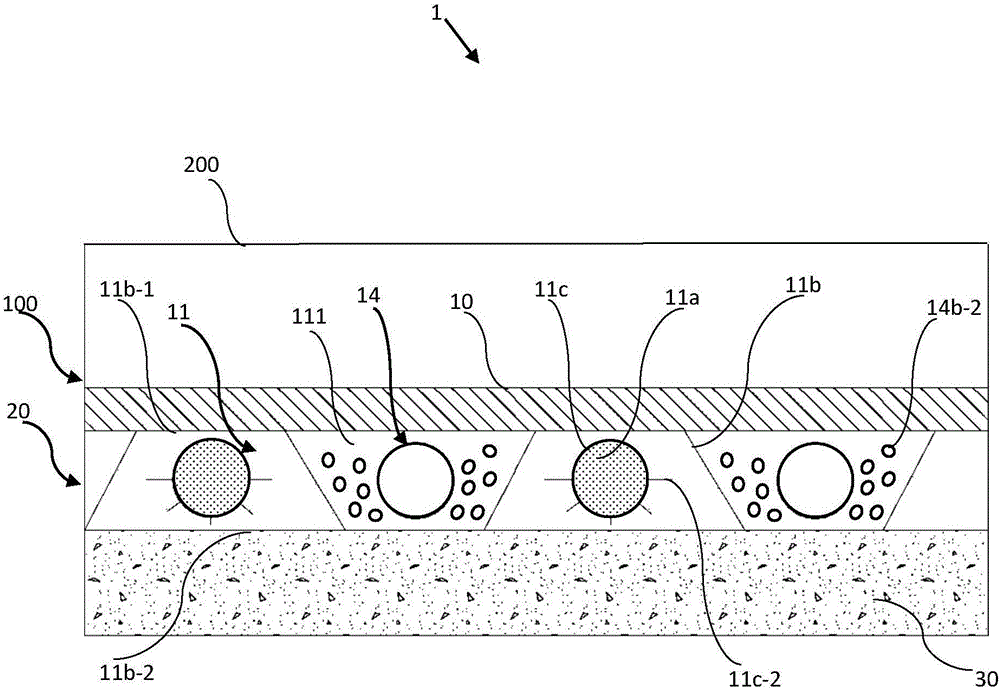

[0025] figure 1 It is a schematic diagram of the cross-sectional structure of the building wall in the embodiment of the present invention.

[0026] Such as figure 1 As shown, a building 1 has a building wall 100 and an interior 200 , and the building wall 100 sequentially includes a protective layer 10 , an insulation layer 20 and a foundation wall 30 from the indoor to the outdoor of the building.

[0027] The protective layer 10 encloses and forms the interior 200 .

[0028] Such as figure 1 As shown, the insulation layer 20 is arranged between the protective layer 10 and the foundation wall 30, including: a plurality of capillary phase change insulation components 11, a first water inlet pipe, a first water return pipe, a heat exchange assembly 14, a second water inlet pipe and Second return pipe.

[0029] A pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com