Patents

Literature

41results about How to "Fast heat storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

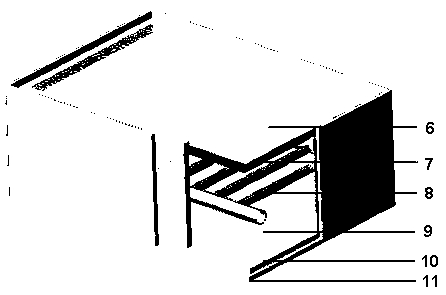

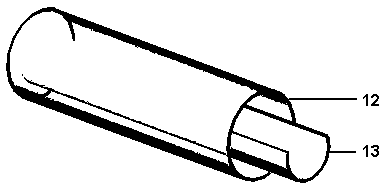

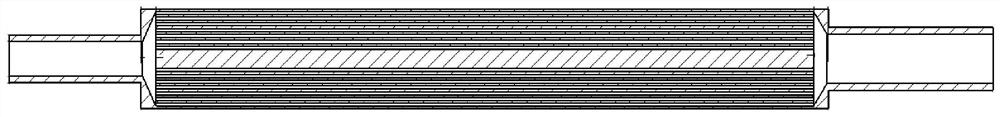

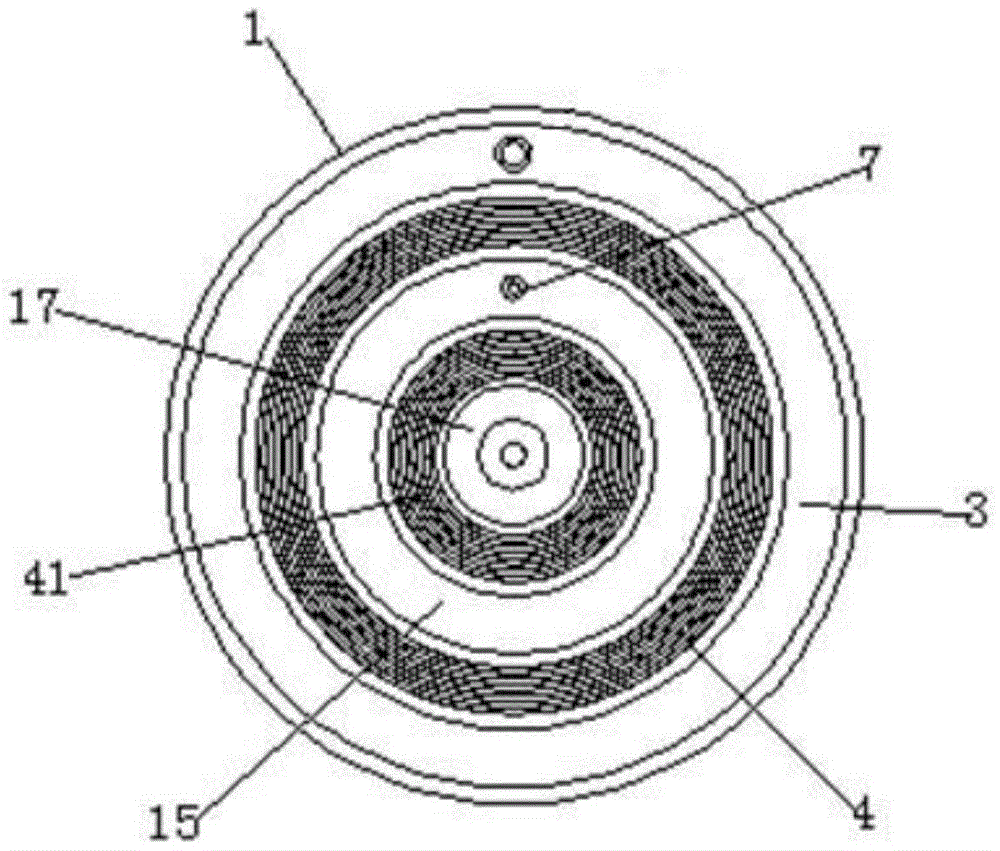

Heat pipe type solid-liquid phase transition heat accumulator

InactiveCN104154788AHigh working reliabilityImprove work efficiencyHeat storage plantsFluid phaseEngineering

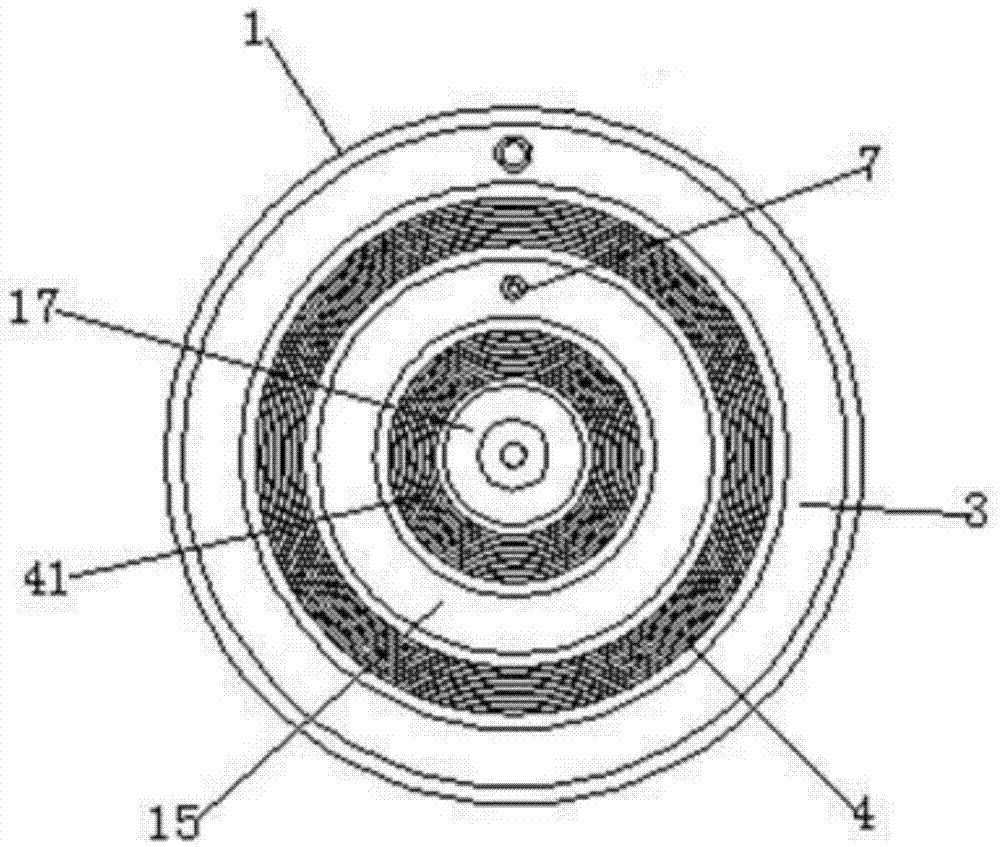

The invention discloses a heat pipe type solid-liquid phase transition heat accumulator which comprises a box body, fins, liquid absorbing cores, phase transition heat accumulating materials and working media. The box body comprises a shell and a main channel formed in the shell, the two ends of the main channel are opened, the main channel is not communicated with the shell, the shell is internally provided with the fins and the phase transition heat accumulating materials, the fins are fixed to the main channel, the fins are annularly arranged about a center shaft of the main channel, and are arranged in the axial direction of the main channel in multiple layers, the ribs are of hollow structures, the liquid absorbing cores are attached to the inner walls of the hollow structures, and the spaces in the fins are filled with the working media for heat transferring between heat or cold sources and the phase transition heat accumulating materials through evaporating and condensing. According to the heat pipe type heat accumulator, the fins achieve heat exchange between the heat or cold sources and the solid and liquid phase transition heat accumulating materials through evaporating and condensing of the internal working media, and the working efficiency of the heat accumulator is improved.

Owner:SOUTHEAST UNIV

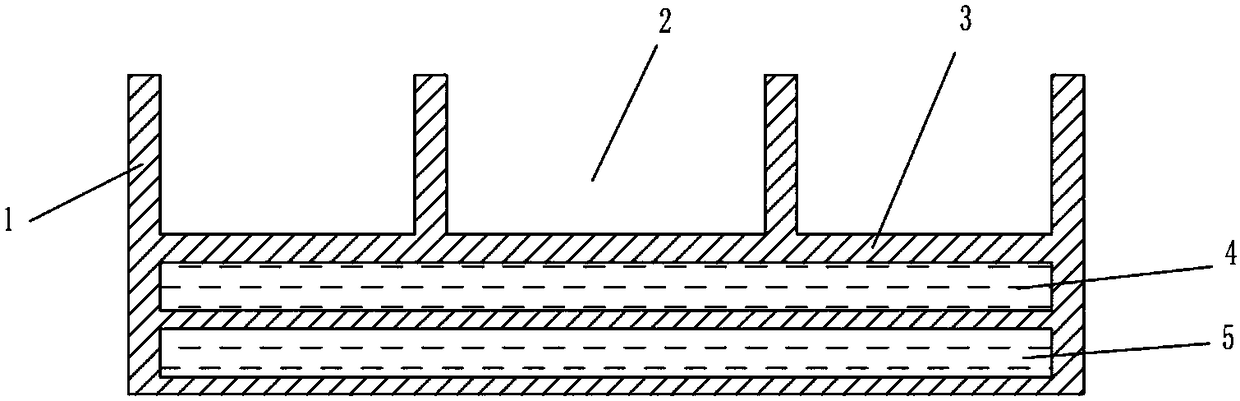

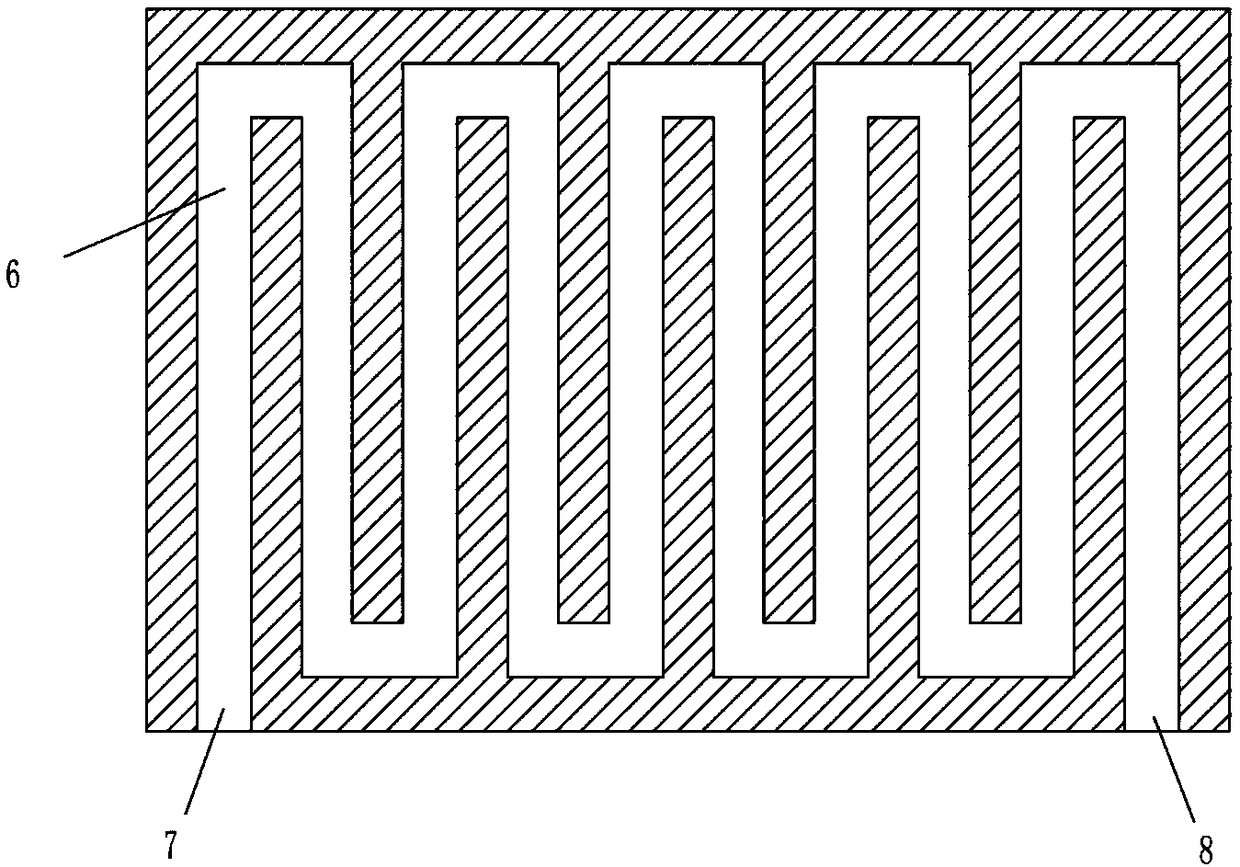

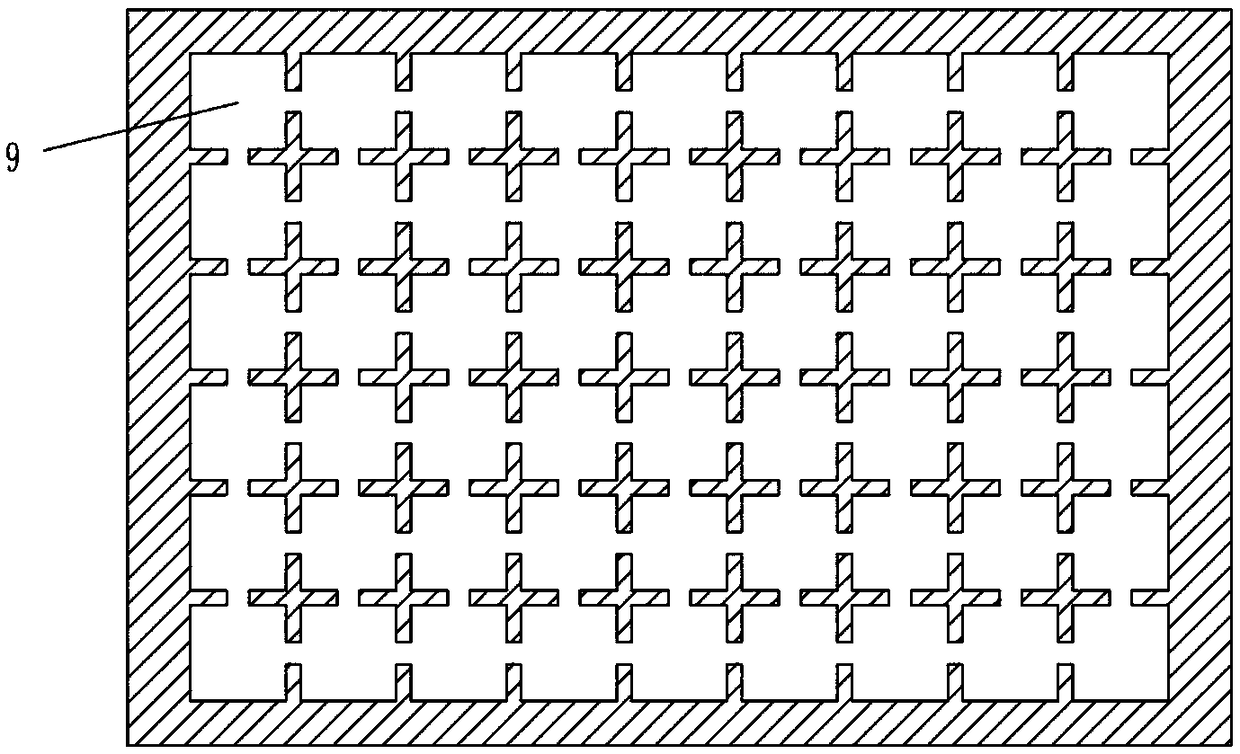

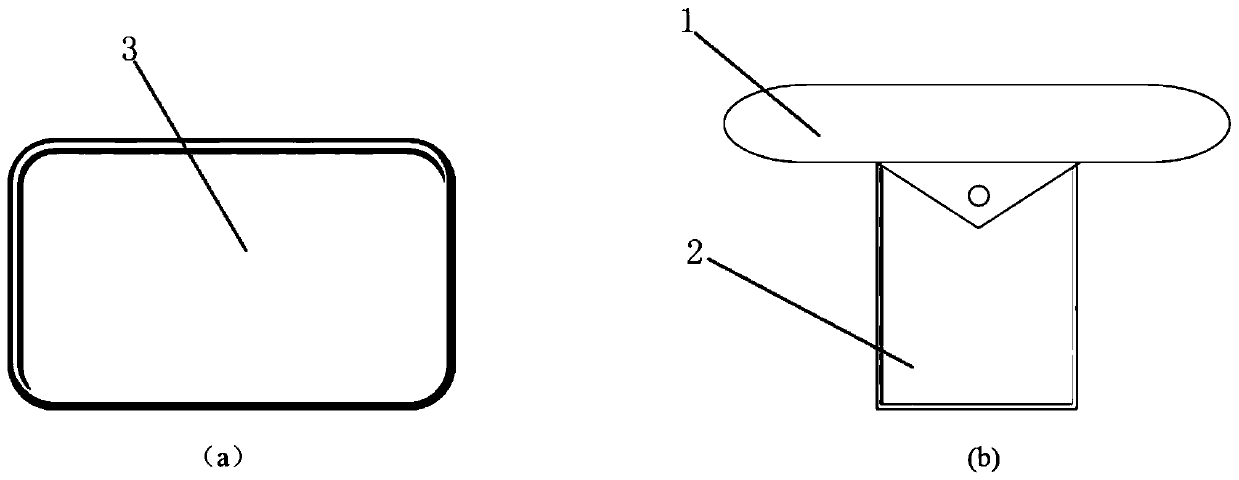

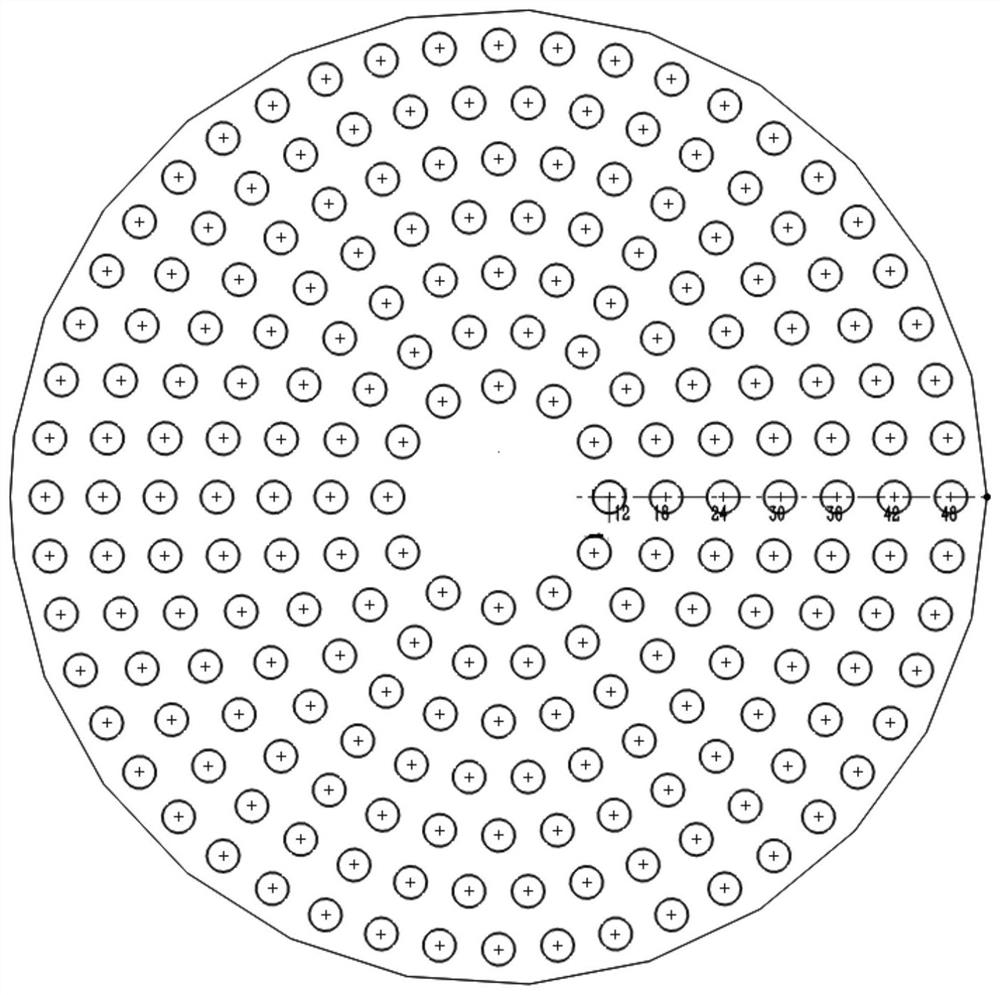

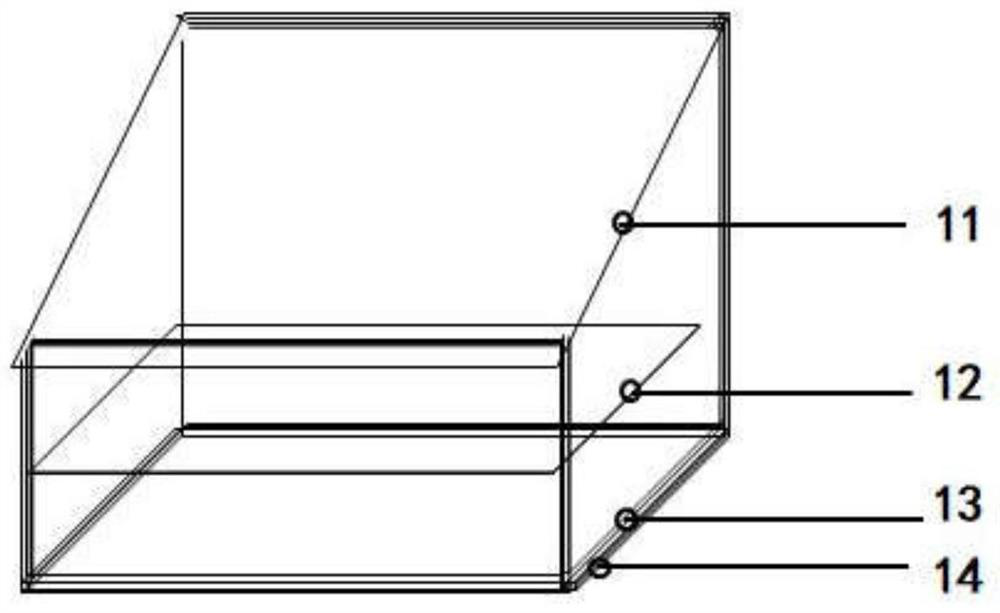

Airborne phased array antenna phase change heat storage liquid cooling heat dissipation box

InactiveCN109037882AMeet cooling needsHeat dissipation fastDe-icing/drying-out arrangementsHoneycombEngineering

The invention discloses an airborne phased array antenna phase change heat storage liquid cooling heat dissipation box, which aims to provide a phased array antenna box body with fast heat dissipation, good effect and high heat dissipation efficiency and combining liquid cooling heat dissipation and phase change heat storage. The heat dissipation box is realized through the following technical scheme: the bottom of a box body (1) is a heat dissipation base (3), the upper layer of the heat dissipation base (3) is a liquid cooling layer (4), and the lower layer is a phase change material layer (5); the liquid cooling layer is provided with an S-shaped liquid cooling flow channel, a liquid cooling inlet and a liquid cooling outlet; the phase change material layer is provided with a pluralityof honeycomb-shaped partition frame cavities enclosed between a liquid cooling layer partition plate and a box body bottom plate; the liquid cooling flow channel transfers heat out by theflow of the liquid cooling coolant; and the phase change material layer transfers heat generated by the phased array antenna to the phase change material stored in the phase change material layer by utilizing a metal partition frame connected between the partition frame cavities. The invention solves the problem that the antenna heat of the phased array antenna cannot be exported in time due to the interruption of the liquid supply under a short-time emergency condition.

Owner:10TH RES INST OF CETC

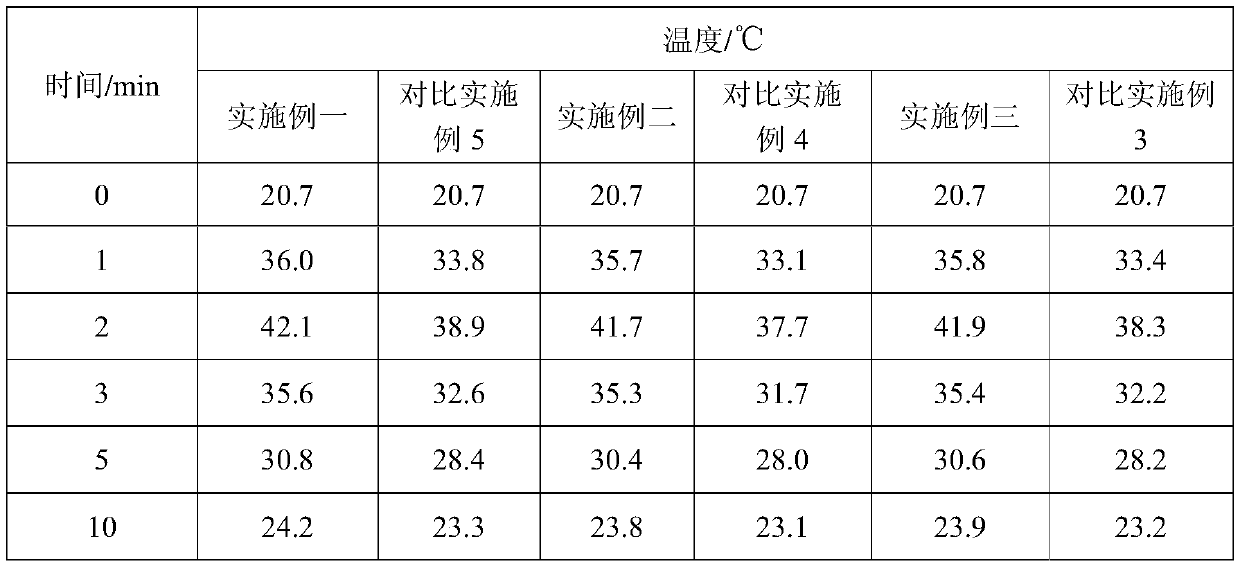

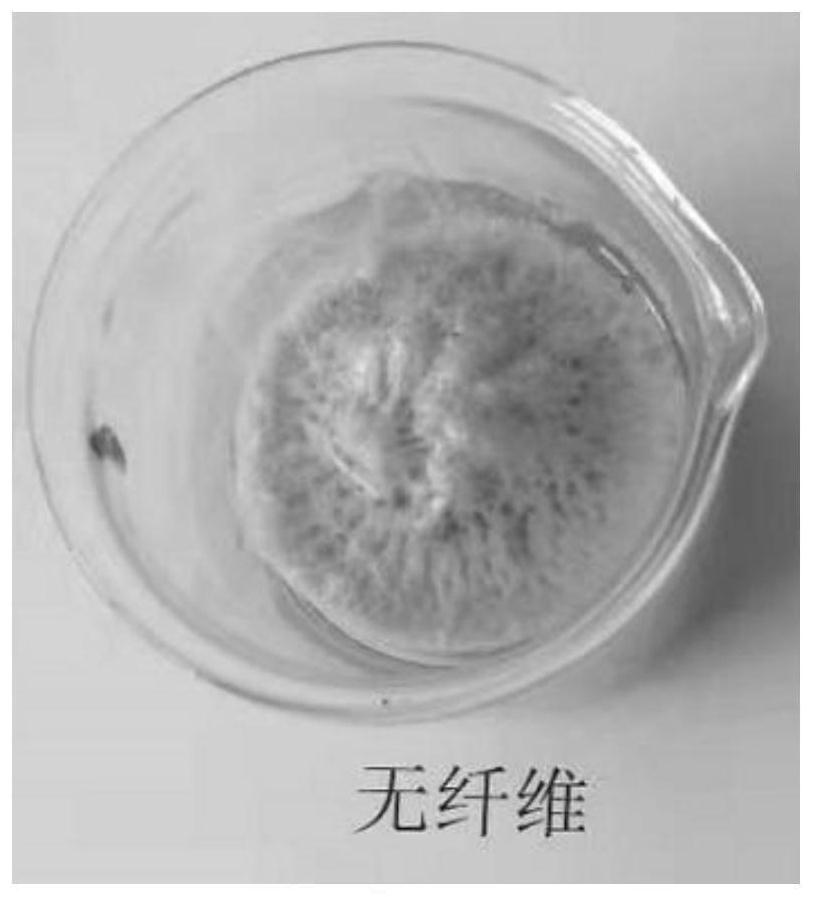

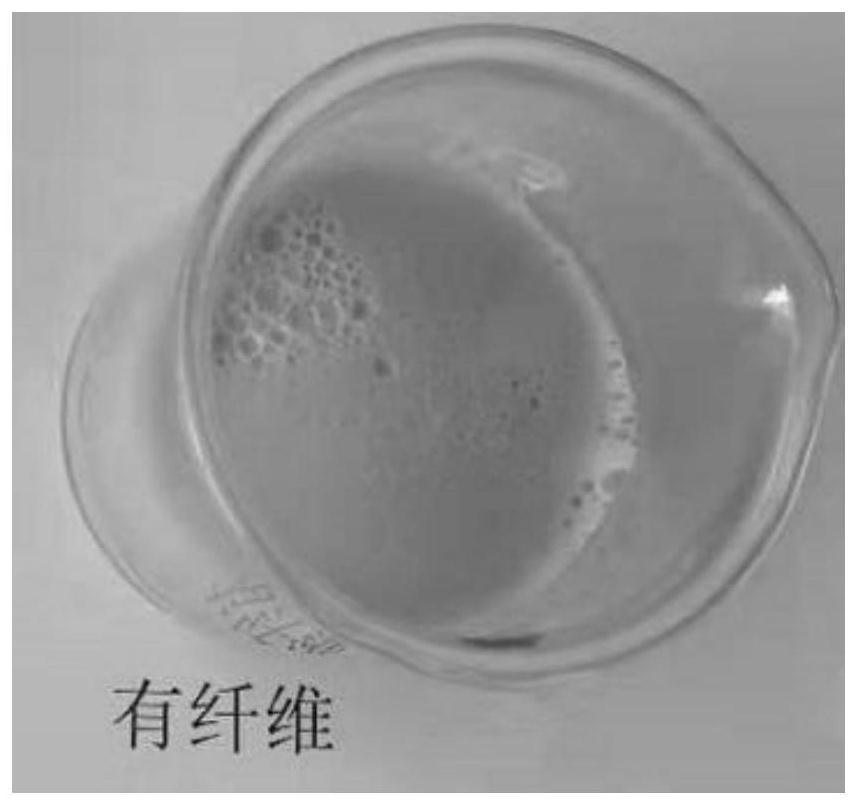

Solid-solid phase change material and preparation method thereof

ActiveCN110669475AHigh latent heat of phase changeLow costHeat-exchange elementsFiberInorganic salts

The invention relates to a solid-solid phase change material and a preparation method thereof, and belongs to the field of phase change energy storage materials. The solid-solid phase change materialcomprises a component A and a component B, wherein the addition amount of the component A is 50-97% and the addition amount of the component B is 3-50% according to the percentage of the total mass ofthe raw materials, wherein the component A is a phase change material component, and comprises the following components in percentage by mass: 0-30% of an inorganic salt, 41-96.8% of water, 1-8% of fiber, 0.1-2% of a dispersant, 0.5-5% of a nucleating agent, 1-8% of a thickening agent and 0.5-6% of a heat conducting medium, wherein the component B is a curing component and comprises the followingcomponents in percentage by mass: 3-25% of isocyanate, 75-97% of hydrophilic polyether polyol and 20 ppm-200 ppm of A retarder accounting for the total mass of the component B. Compared with the existing water-based phase change material, the solid-solid phase change material provided by the invention not only furthest retains the characteristics of high phase change latent heat and low cost of the water-based phase change material, but also has no leakage risk and better heat conductivity.

Owner:SHANDONG ANLENG NEW MATERIAL TECH CO LTD

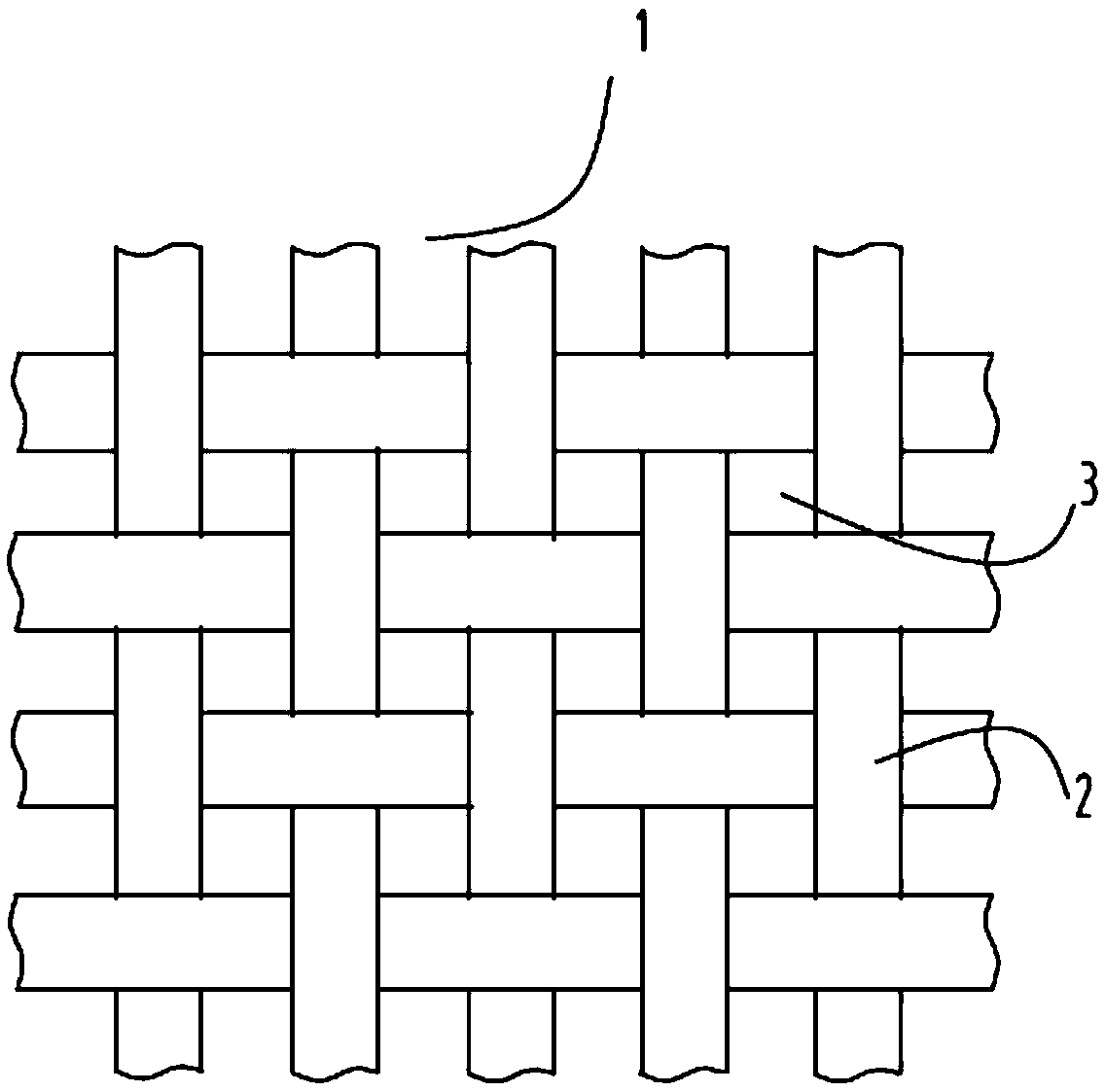

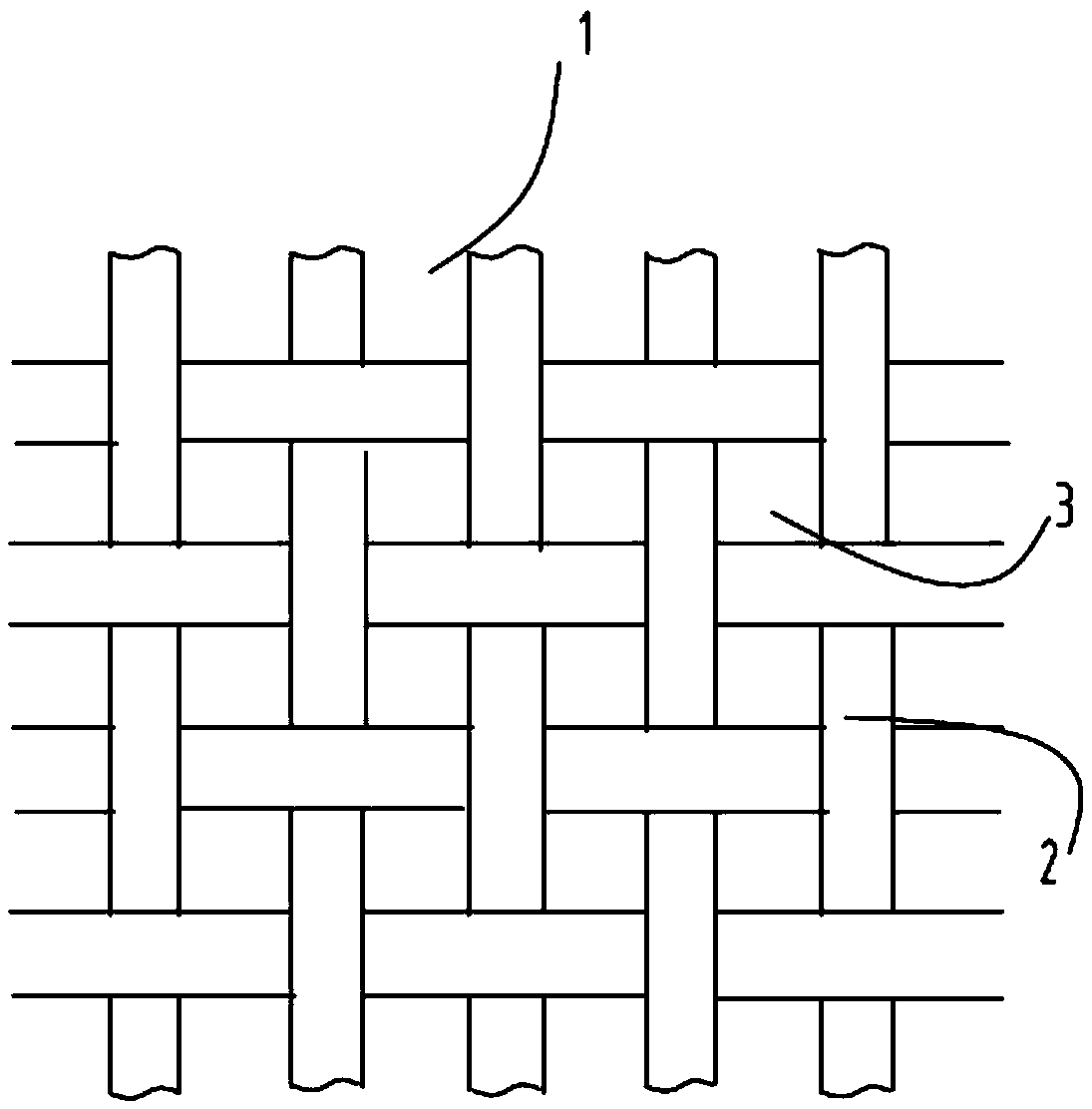

Functional textile fabric

The invention relates to a functional textile fabric. The functional textile fabric comprises a functional unit, wherein the functional unit comprises yarns containing heating and dehumidifying functional textile fibers; the yarns have number of twists of 100-200T / m; the heating and dehumidifying functional textile fibers comprise crimped fiber materials and nano units; the crimped fiber materials account for 99.91-99.95wt% of the total functional textile fibers, achieve crimp percentage reduction through water wetting and are formed by polyester resin components and polyamide resin components in a ratio of 1 to 1; the polyester resin components and the polyamide resin components have different self extensibility and crimp percentages during water absorption; the nano units account for 0.05-0.09wt% of the total functional textile fibers and comprise microparticles in sizes of 8500-9000nm; the microparticles comprise 300-500 of zinc, 350-450 of aluminium and 150-350 of iron by weight. The functional textile fabric has the beneficial effect that the clothes airing efficiency is improved through combined action of temperature rise, heat storage and increase of gaps of the fabric.

Owner:JIANGSU HAIYANG CHEM FIBERS +1

Heat storage device adopting concentric compounding a phase change material and water

The invention discloses a heat storage device adopting concentric compounding a phase change material and water. The heat storage device comprises a cylindrical shell body; for the shell body, a hot water inlet pipe is arranged at the upper left part, a hot water return pipe is arranged at the lower left part, a cold water inlet pipe is arranged at the lower right part, and a hot water outlet pipeis arranged in the center of the top surface; a cylindrical metal cylinder is concentrically installed in the center in the shell body; a phase change heat storage material is packaged in the metal cylinder; the outer side wall of the metal cylinder is fixedly connected with the inner side wall of the shell body through a metal fixed rod, so that the metal cylinder can be concentrically installedin the center in the shell body; a space outsides the metal cylinder is filled with the water; a heat exchange pipe is installed on the outer side of the metal cylinder in a surrounding manner; and awater inlet at the upper end of the heat exchange pipe communicates with the hot water inlet pipe, and a water outlet at the lower end communicates with the hot water return pipe. Compared with an existing heat storage device, the heat storage device is capable of performing heat storage at a faster speed.

Owner:北方瑞能(内蒙古)集团有限公司

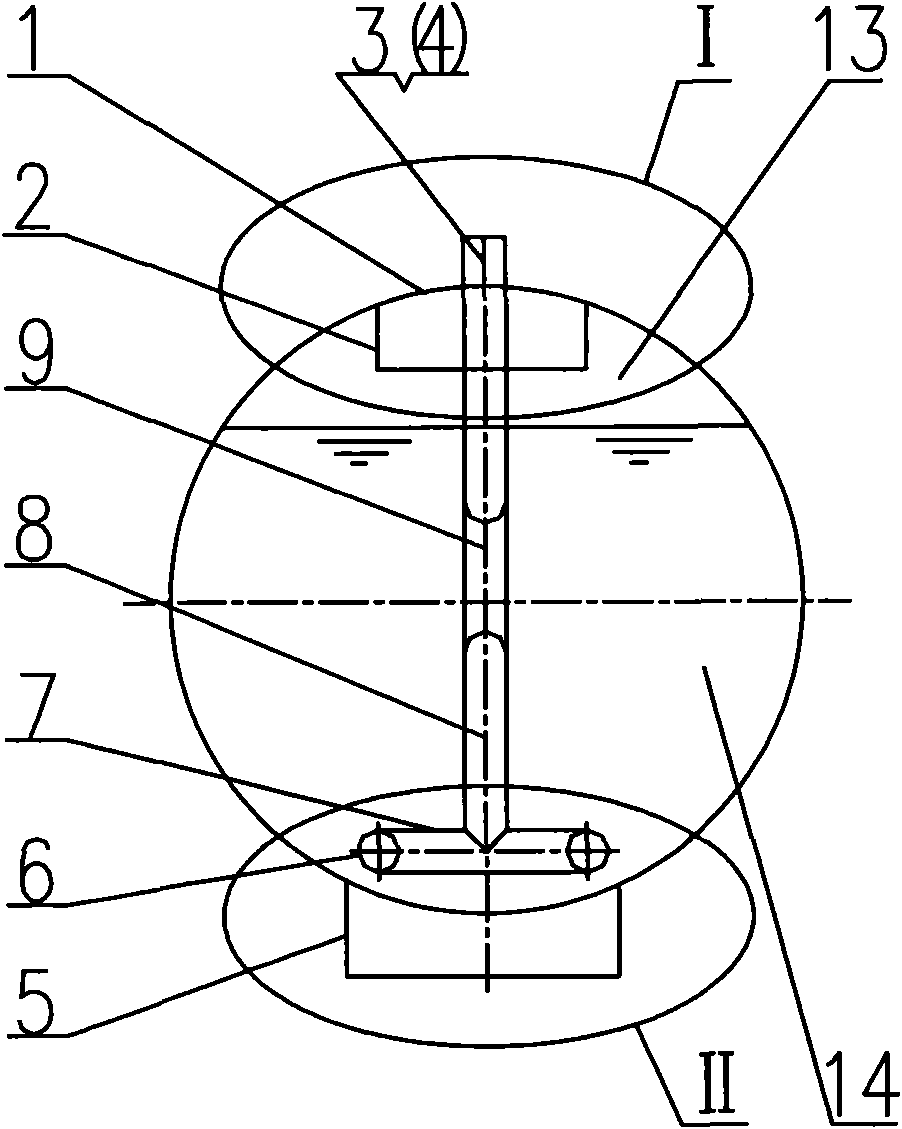

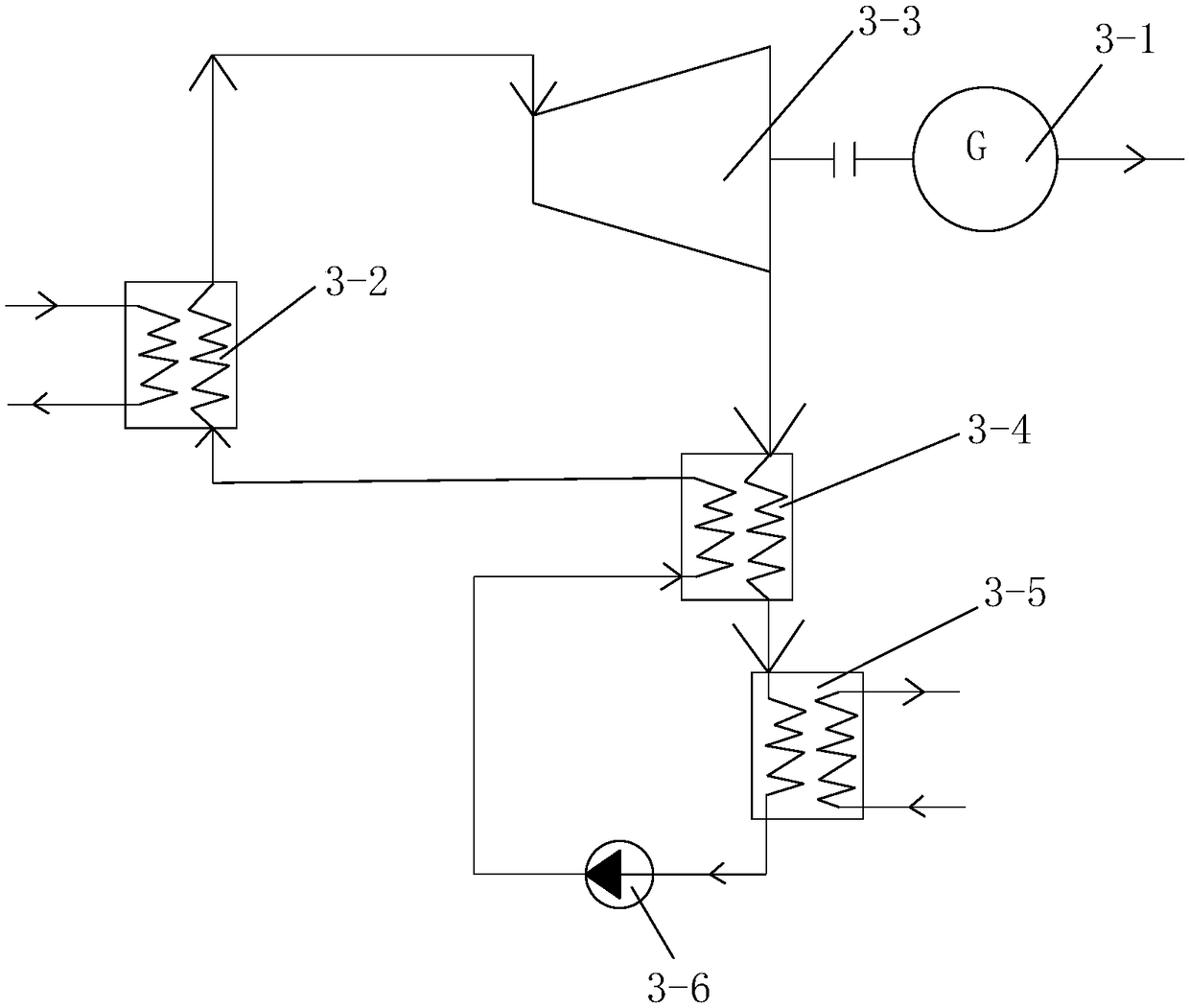

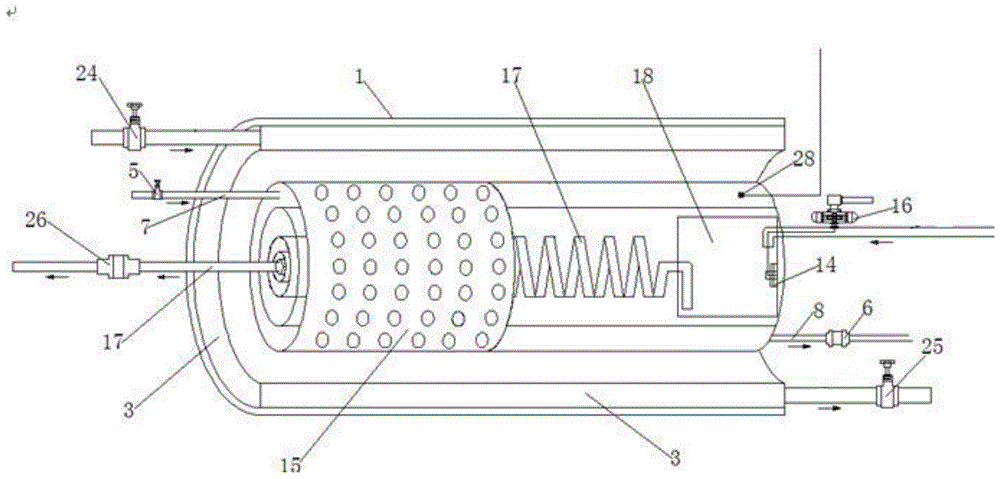

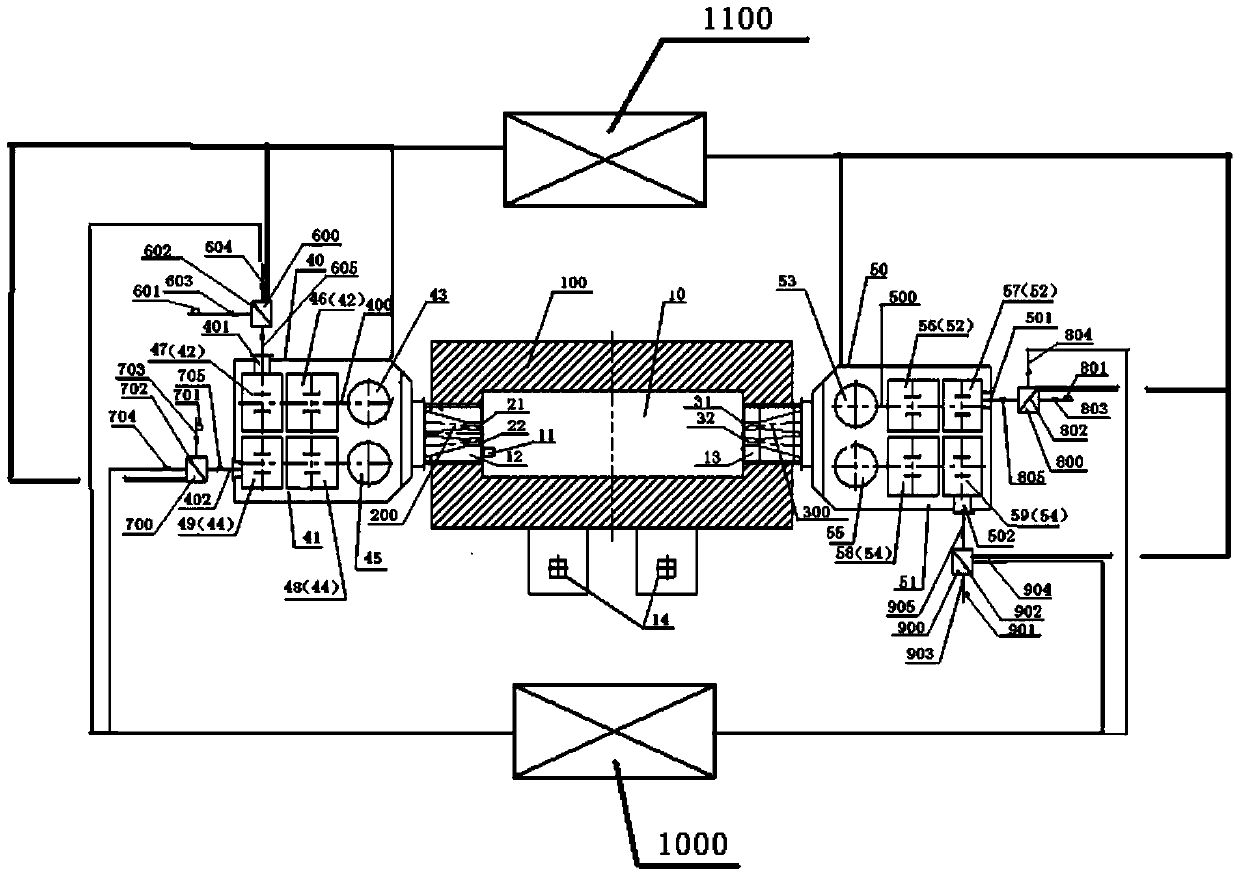

Coupling type waste heat energy recovering system for large phase-change heat storage cylinder

ActiveCN104501290AIncrease the heat exchange areaFast heat transferHeat storage plantsSpace heating and ventilation detailsDirect heatingEngineering

The invention provides a coupling type waste heat energy recovering system for a large phase-change heat storage cylinder. The system comprises a large phase-change heat storing cylinder assembly and a waste heat energy recovering assembly; the hot source inlet end of the large phase-change heat storing cylinder assembly is connected with a waste heat water source, and the heat supply outlet end of the large phase-change heat storing cylinder assembly is respectively connected with a direct heating device and an indirect heating device. The system is simple in structure; the heat of waste water is fully recovered and recycled; therefore, the function of fast storing heat and radiating heat can be achieved; the system is suitable for recycling of afterheat from the waste heat of liquid.

Owner:SOUTHEAST UNIV

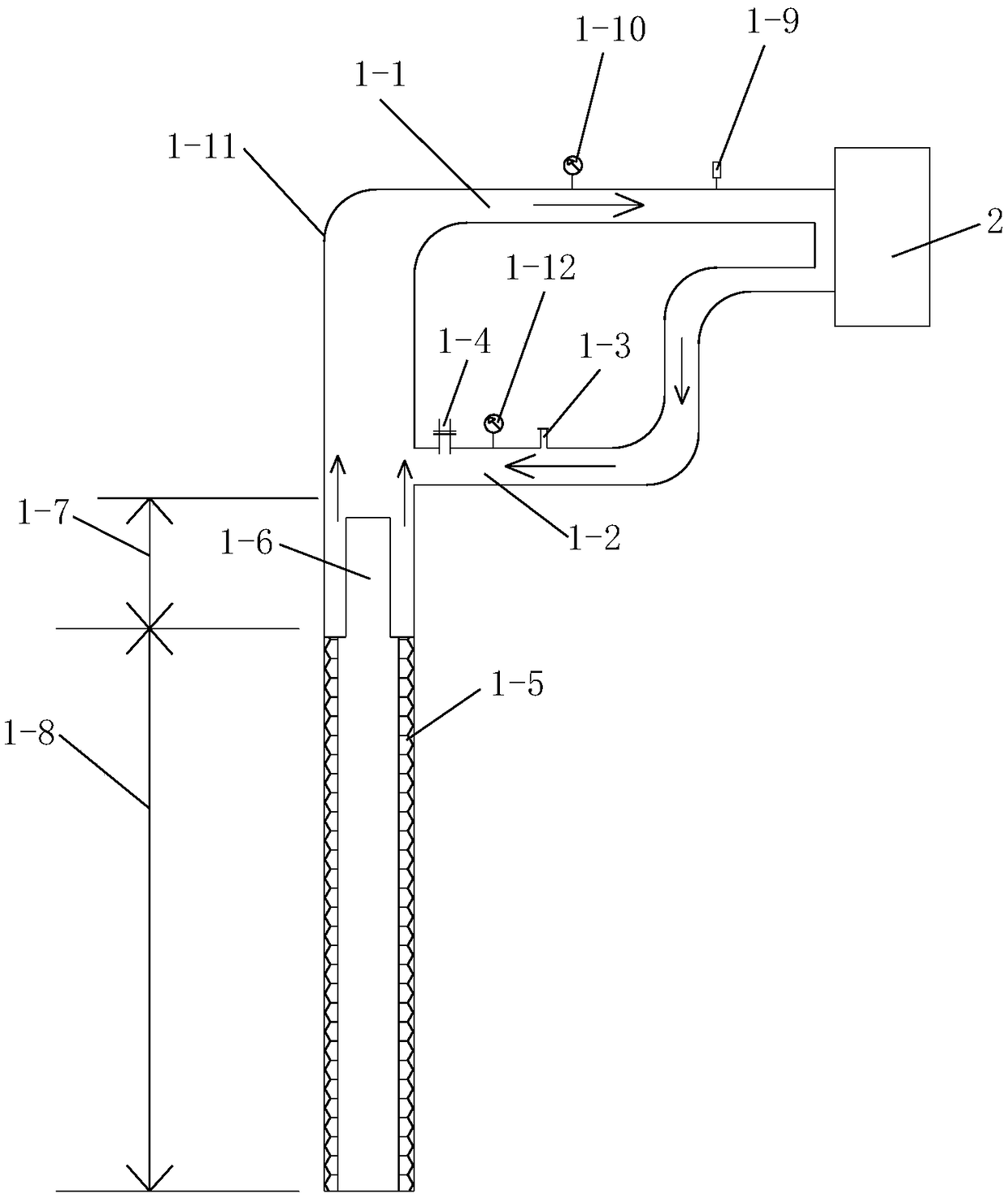

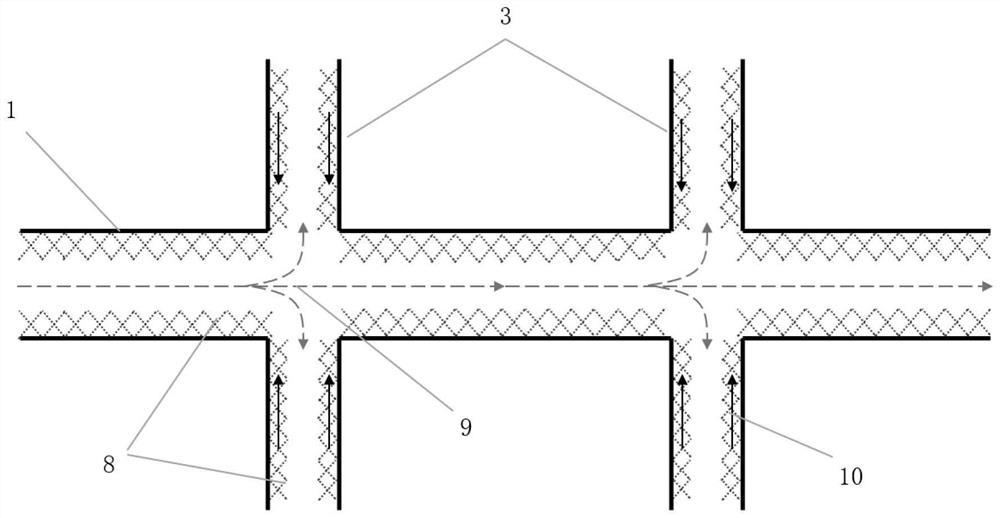

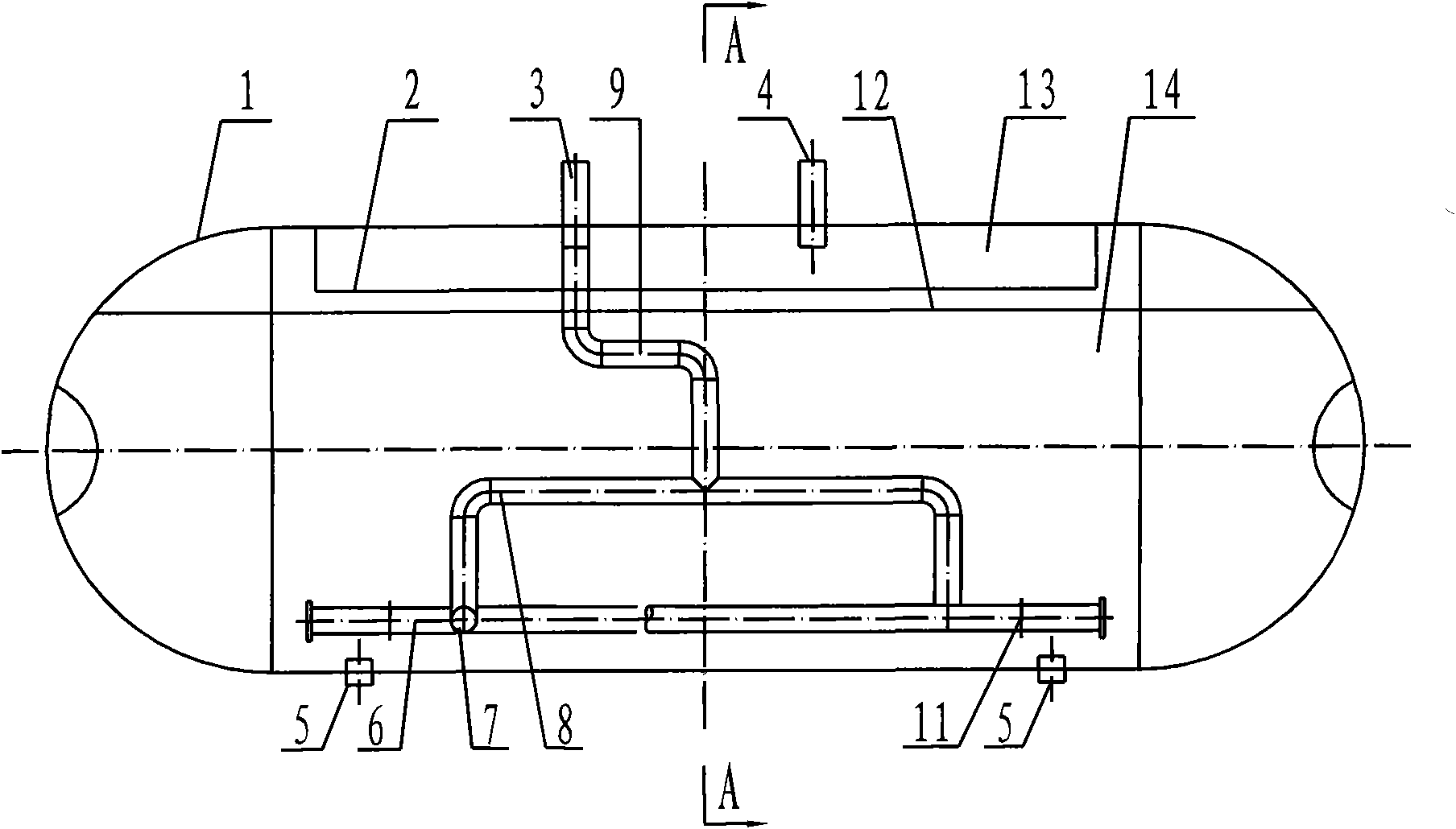

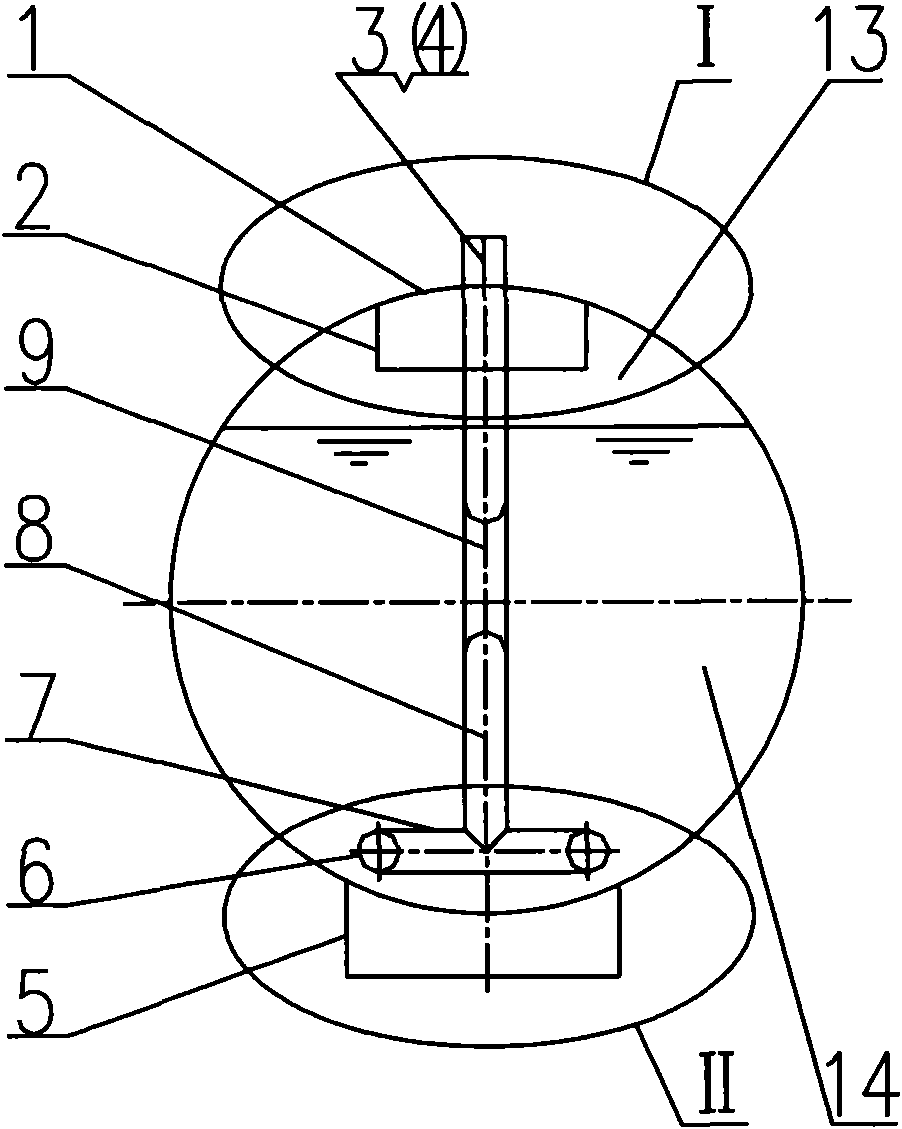

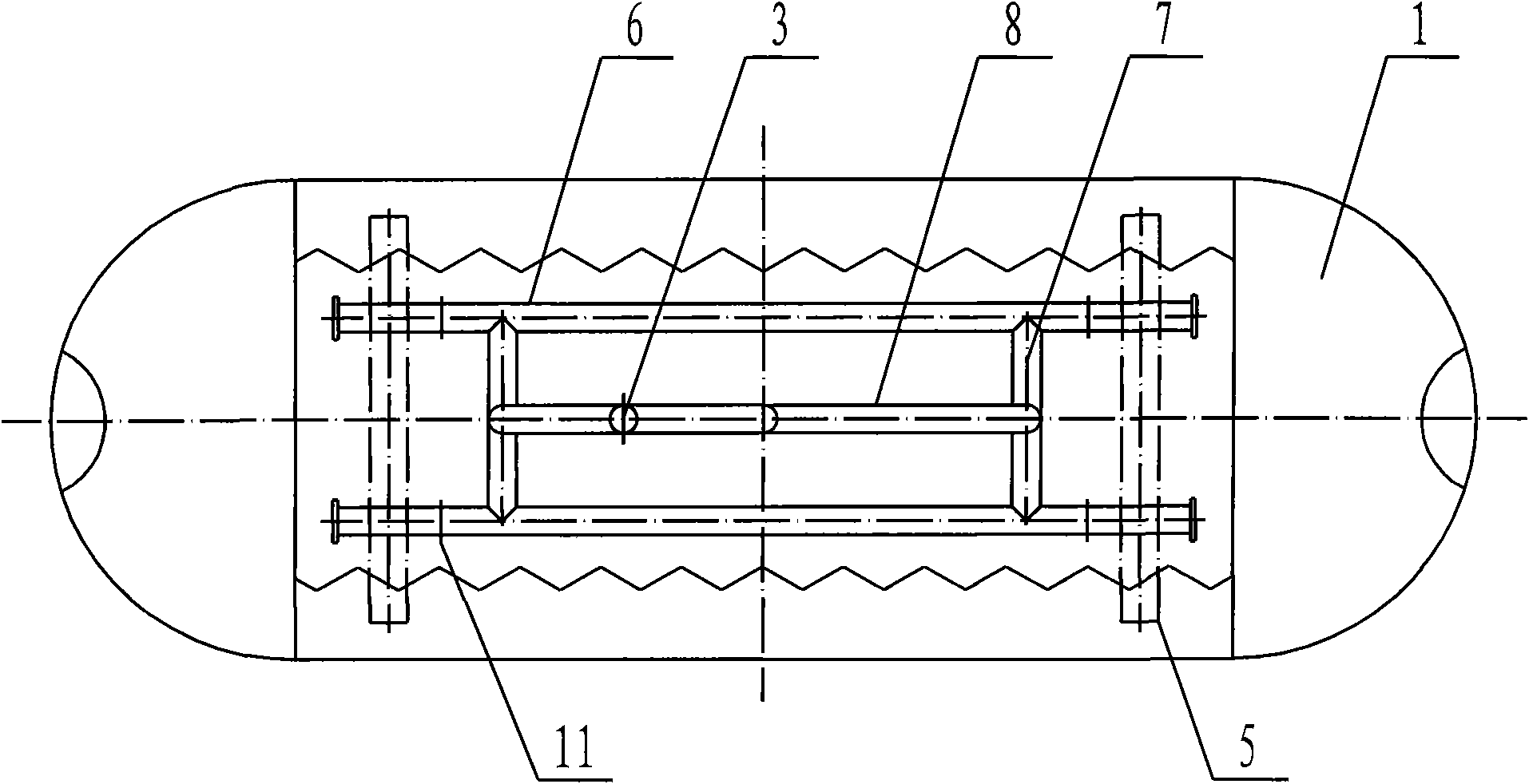

Low-water-level horizontal steam distributing pipe bottom-heating steam-jetting heat storage device

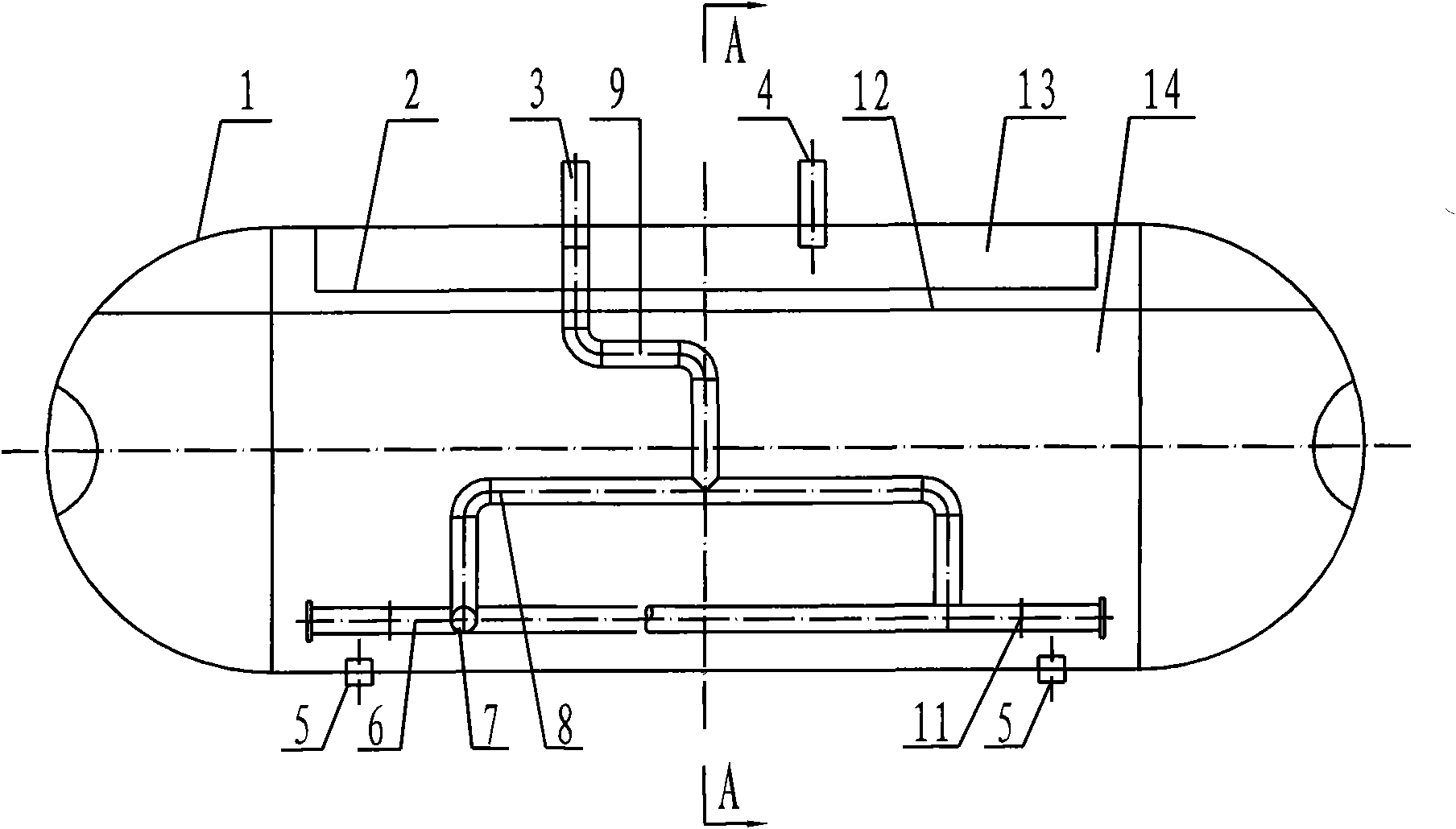

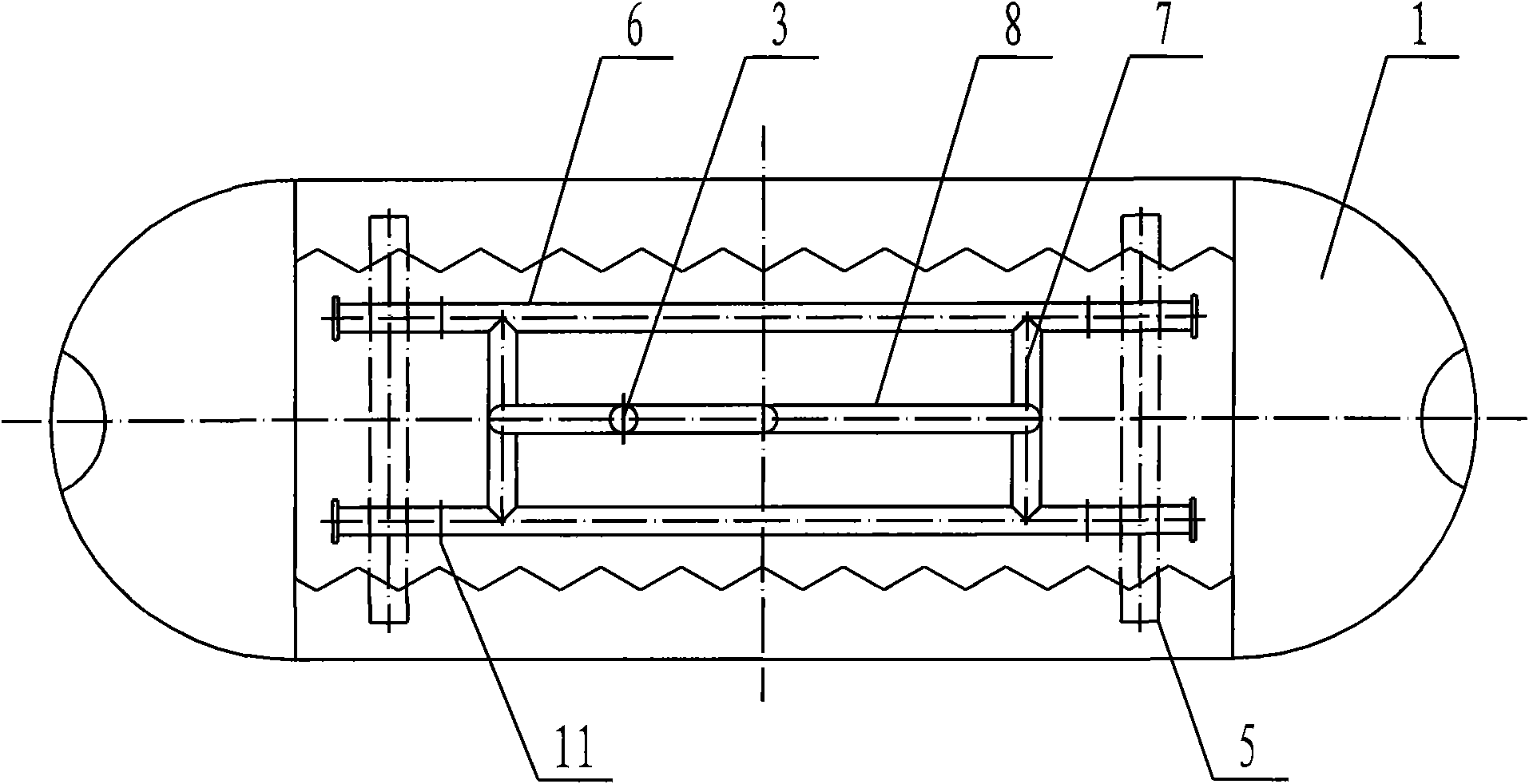

The invention discloses a low-water-level horizontal steam distributing pipe bottom-heating steam-jetting heat storage device, which comprises a heat storage device body, a heated steam distributing pipe and a steam connecting pipeline, wherein the heated steam distributing pipe is horizontally arranged on the lower part of a water space inside a heat storage device shell along the length direction of the heat storage device, two ends of the heated steam distributing pipe are closed, the inner sides at quarter length of the heated steam distributing pipe are respectively provided with a steam inlet, and an upper semicircular pipe wall of the heated steam distributing pipe is provided with a plurality of steam jetting holes; and the steam connecting pipe comprises a first connecting pipe, two second connecting pipes and a third connecting pipe, wherein one end of the first connecting pipe is communicated with a steam inlet pipe, the other end of the first connecting pipe is communicated with the middle part of the third connecting pipe, two steam outlets facing downwards on two ends of the third connecting pipe are respectively communicated with the middle parts of the two second connecting pipes, and two ends of each second connecting pipe are respectively connected with the steam inlets at the inner side of the heated steam distributing pipe. Due to the adoption of the steam heat storage device, the economic benefit and the social benefit of energy conservation, emission reduction and carbon reduction of the heat storage device can be improved.

Owner:BEIJING MINGCHENG TECH DEV

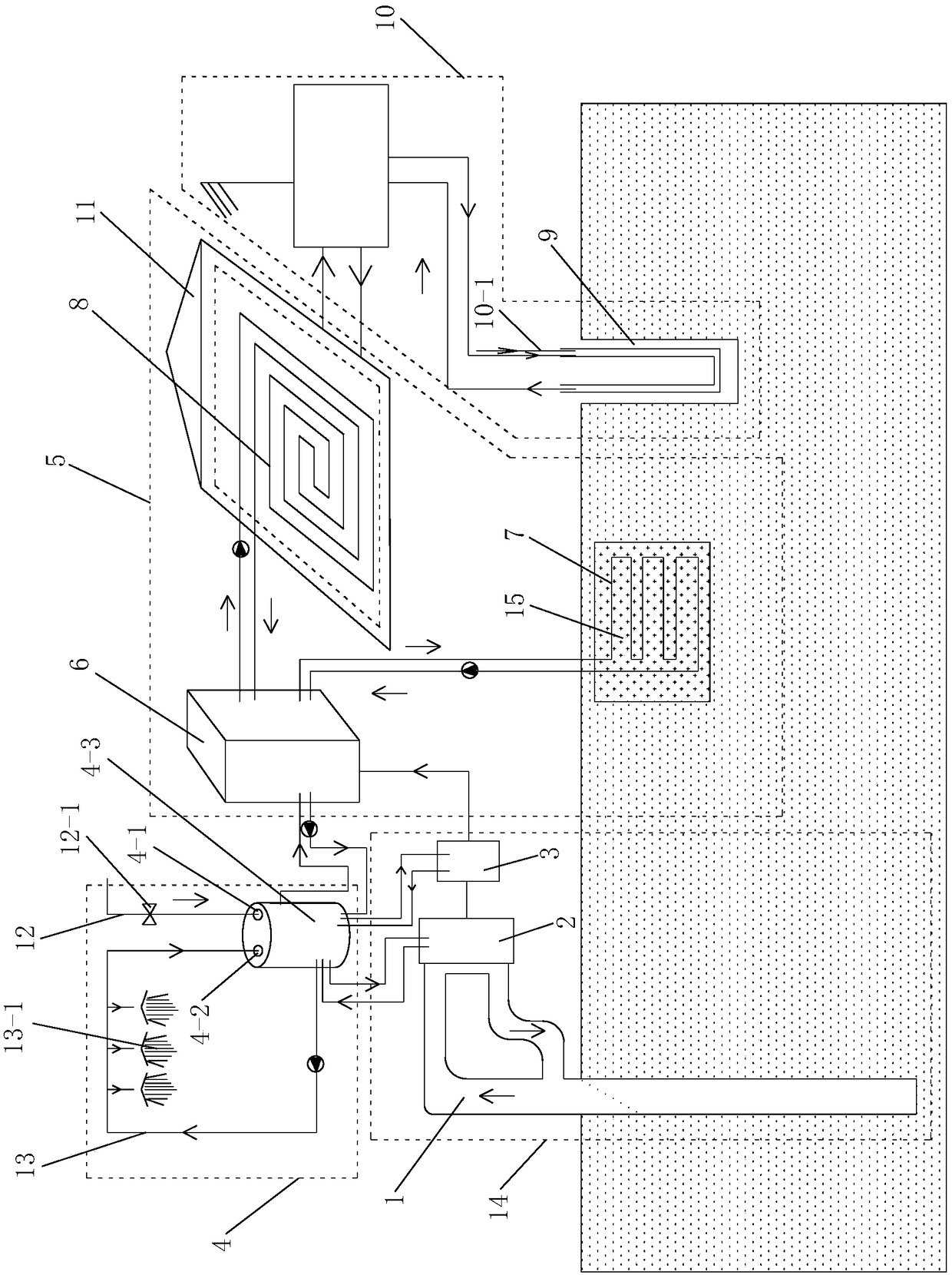

Mine waste heat cascade utilization integrated system

ActiveCN108825289ARealize cascade utilization of waste heatReduce the temperatureMining devicesSteam usePlate heat exchangerFresh air

The invention discloses a mine waste heat cascade utilization integrated system. The mine waste heat cascade utilization integrated system comprises a mine deep waste heat utilization system and a mine shallow waste heat utilization system. The mine deep waste heat utilization system comprises a power supply system and a hot water supply system. The power supply system comprises a deep waste heatpipe collecting system, a first heat exchanger and a power generating system which are connected in sequence, and the first heat exchanger and the power supply system are both connected with the hot water supply system. The mine shallow waste heat utilization system comprises a water heating and cooling system and a fresh air treatment system. The water heating and cooling system includes a buriedpipe, a heat pump unit and a floor radiant pipe system. Both ends of the buried pipe and both ends of a floor radiant pipe are separately connected with the heat pump unit, and the interior of a house is connected with the fresh air treatment system. The heat pump unit and the power generating system are both connected with the heat water supply system. The mine waste heat cascade utilization integrated system utilizes the waste heat of a mine by different level to realize the maximum utilization of the waste heat; and reduction the heat damage of the mine is achieved, energy saving and environmental protection are achieved, and the structure is simple.

Owner:XIAN UNIV OF SCI & TECH

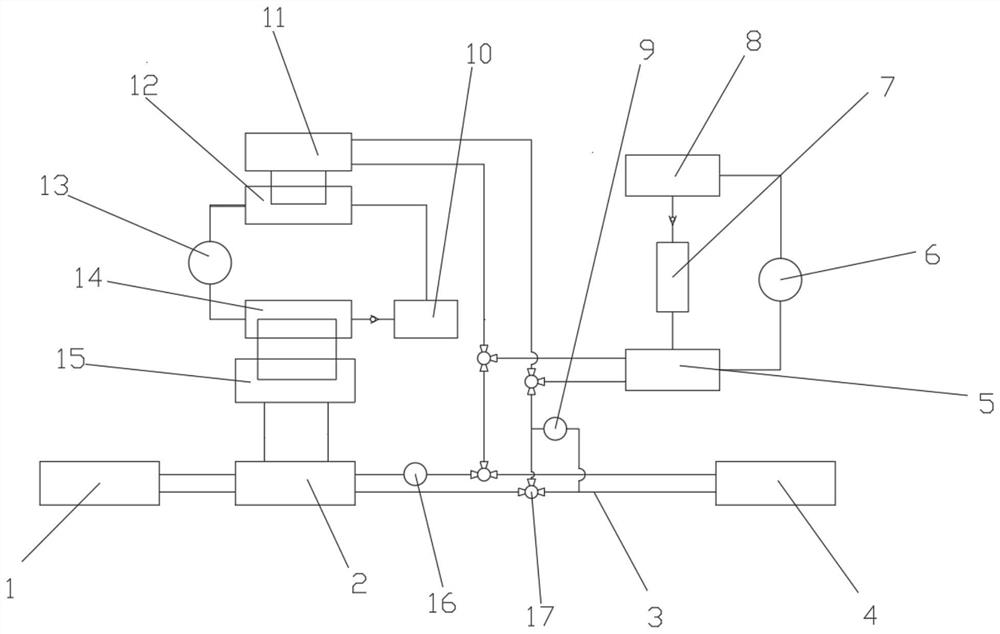

Solar energy and heat pump combined heat supply system and method suitable for alpine region

PendingCN112325372AAvoid damageReduce wasteSolar heating energyCentral heating with accumulated heatThermodynamicsCollector device

The invention discloses a solar energy and heat pump combined heat supply system and method suitable for an alpine region. According to the solar energy and heat pump combined heat supply system, a solar heat collector, a heat pump and a heat storage device are combined, so that the solar energy and heat pump combined heat supply system achieves stable and continuous heat supply in the alpine region, when the sun is insufficient or the temperature of external air is too low, the solar energy and heat pump combined heat supply system is overturned into equipment when not working, a heat collection pipe is protected, the heat collection pipe is prevented from being damaged by external impact, the service life of the equipment is greatly prolonged, and an arranged cleaning mechanism can be used for cleaning and maintaining the heat collection pipe, so that the situation that the solar heat collection efficiency is reduced due to dust attached to the heat collection pipe is avoided, the heat supply efficiency of the equipment is prevented from being reduced, the energy utilization rate is guaranteed, and the solar energy and heat pump combined heat supply system has the beneficial effects that heat supply is stable in connection, the service life of the equipment is long, the heat storage speed of the equipment is fast, the energy utilization rate is high, and the solar heat collector is cleaned and maintained.

Owner:山东齐昊新能源科技有限公司

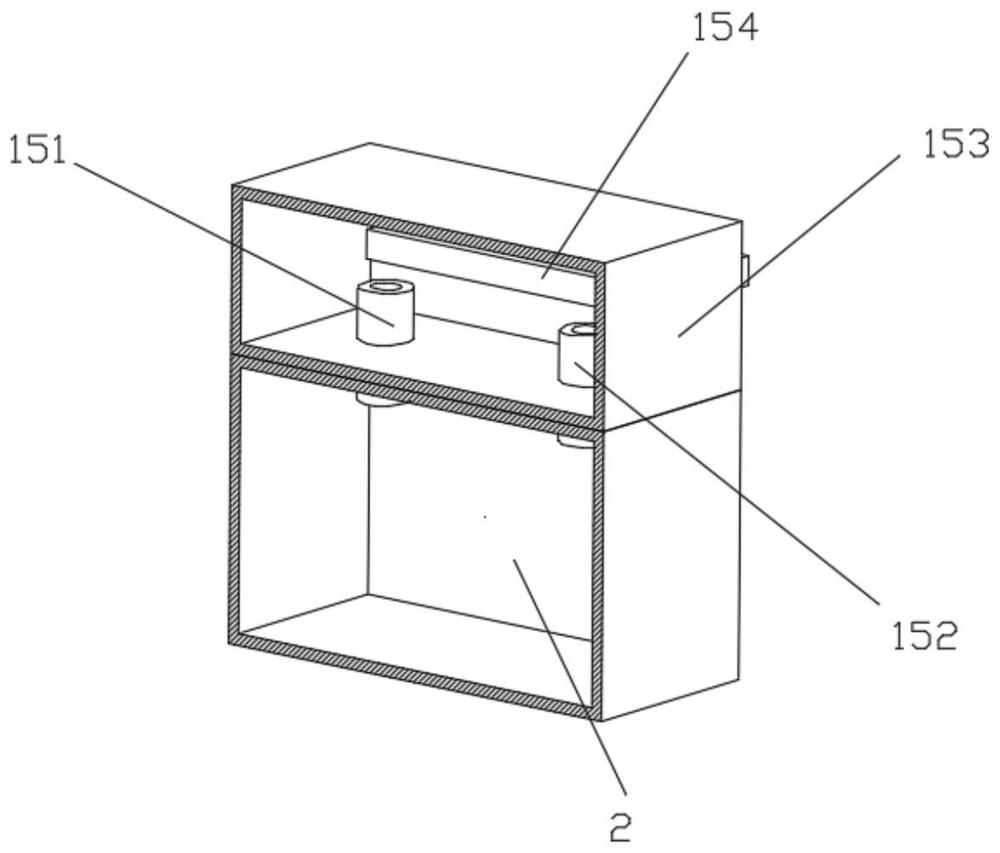

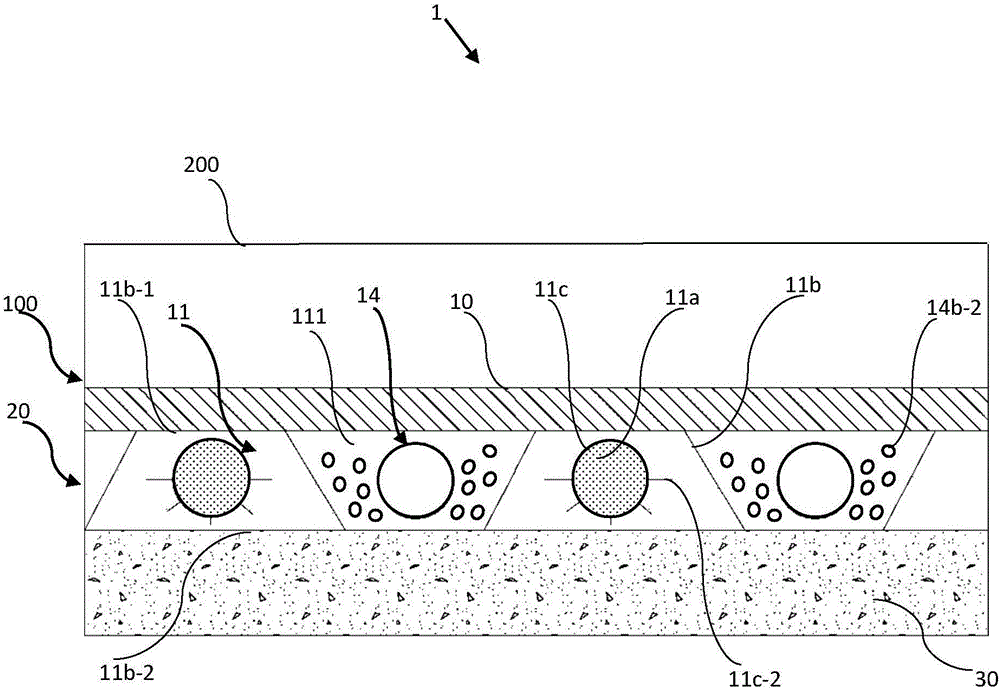

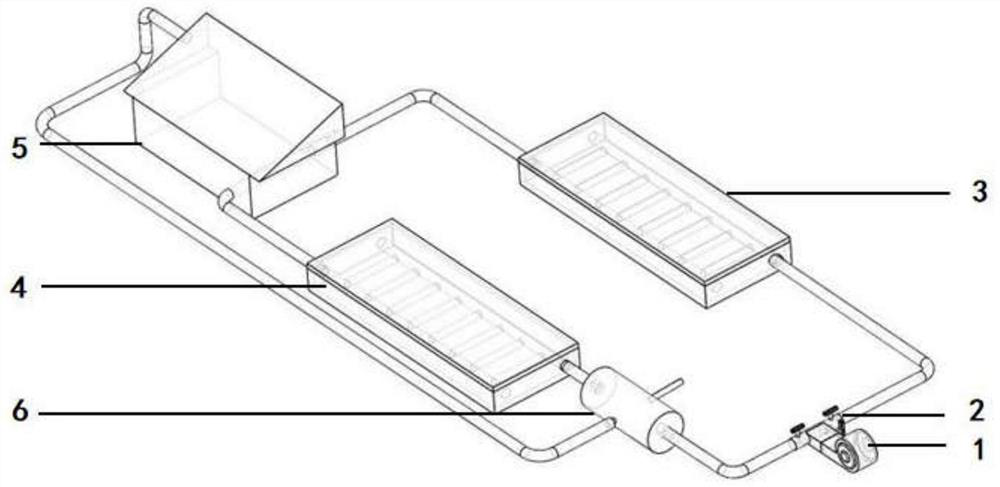

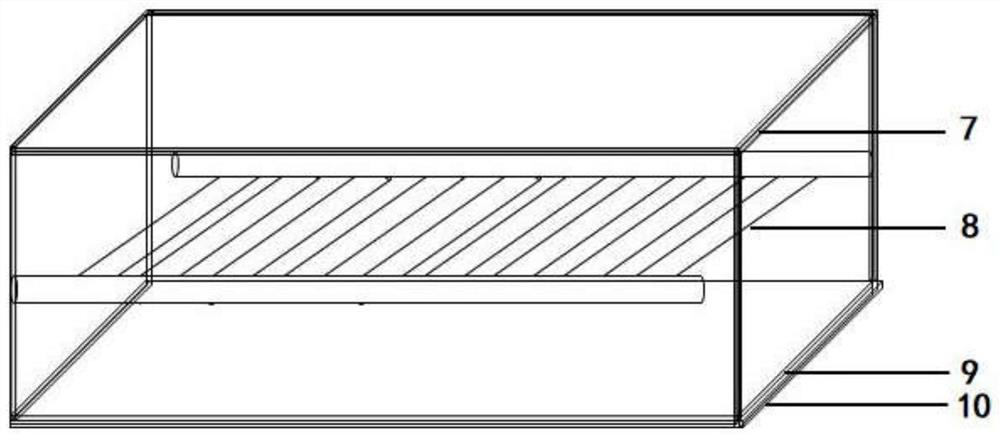

Phase change heat storage system

InactiveCN109945713AImprove efficiencyFast heat storageHeat storage plantsLayered structurePhase-change material

The invention relates to a phase change heat storage system which comprises a heat storage box body, a circulating fan and a heat insulation air pipe; a partitioning frame and heat exchangers are arranged in the heat storage box body; the two heat exchangers are separately arranged at two ends of the partitioning frame; the partitioning frame is of an upper-lower layered structure; a plurality ofheat storage units are arranged left and right; a heating plate and a phase change material plate are placed in each heat storage unit; and an air outlet and an air inlet which are formed in the leftend and the right end of the heat storage box body are connected by means of the heat insulation air pipe and the circulating fan. The phase change heat storage system has the advantages that fillingand replacing of the phase change material are more convenient and quicker, hot air is circularly utilized in the system, and the temperature of hot air in the inlet and the outlet can be controlled,so that the utilization efficiency of energy sources is improved, the cost is reduced, and the more environmental protection purpose is realized.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

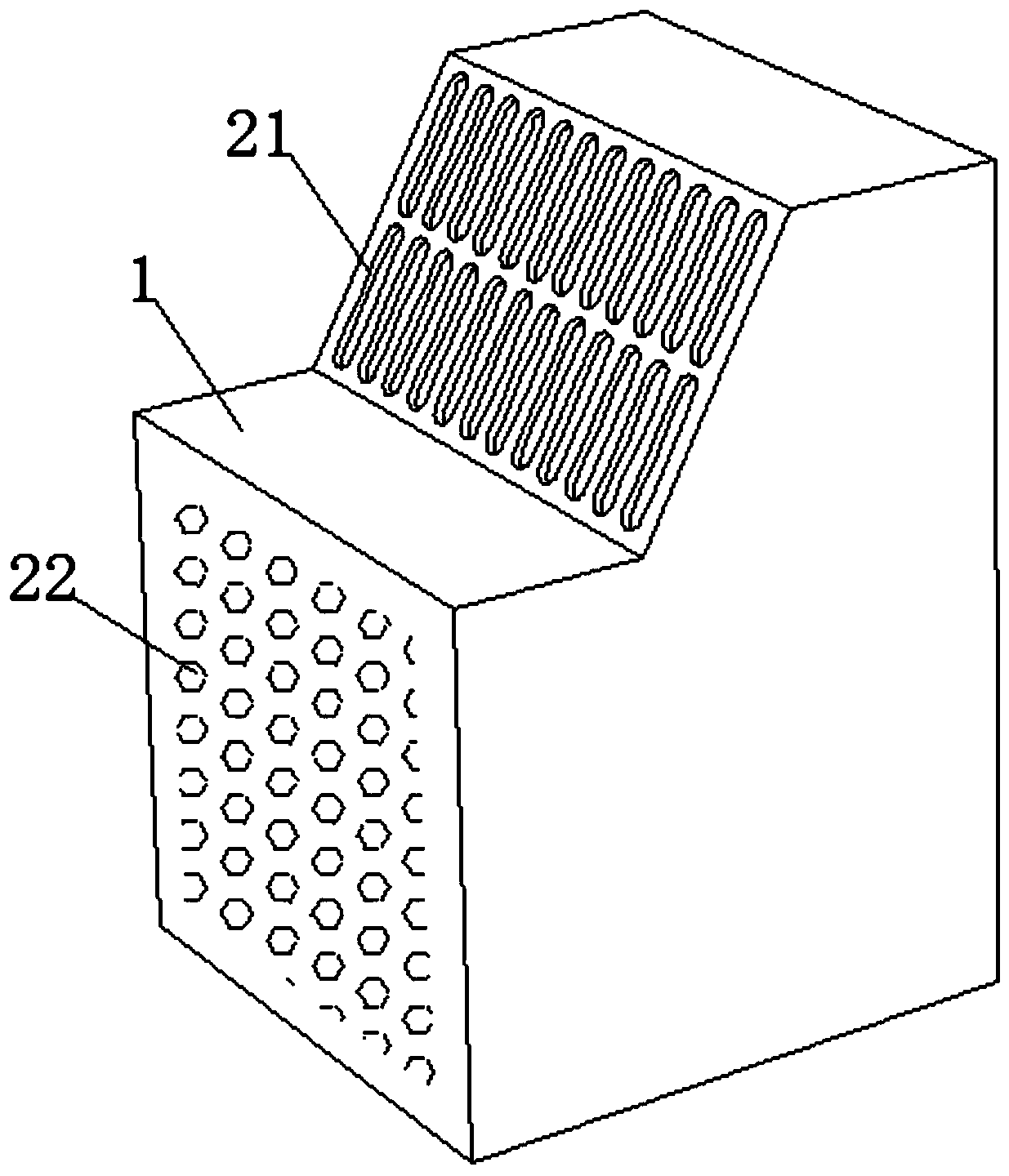

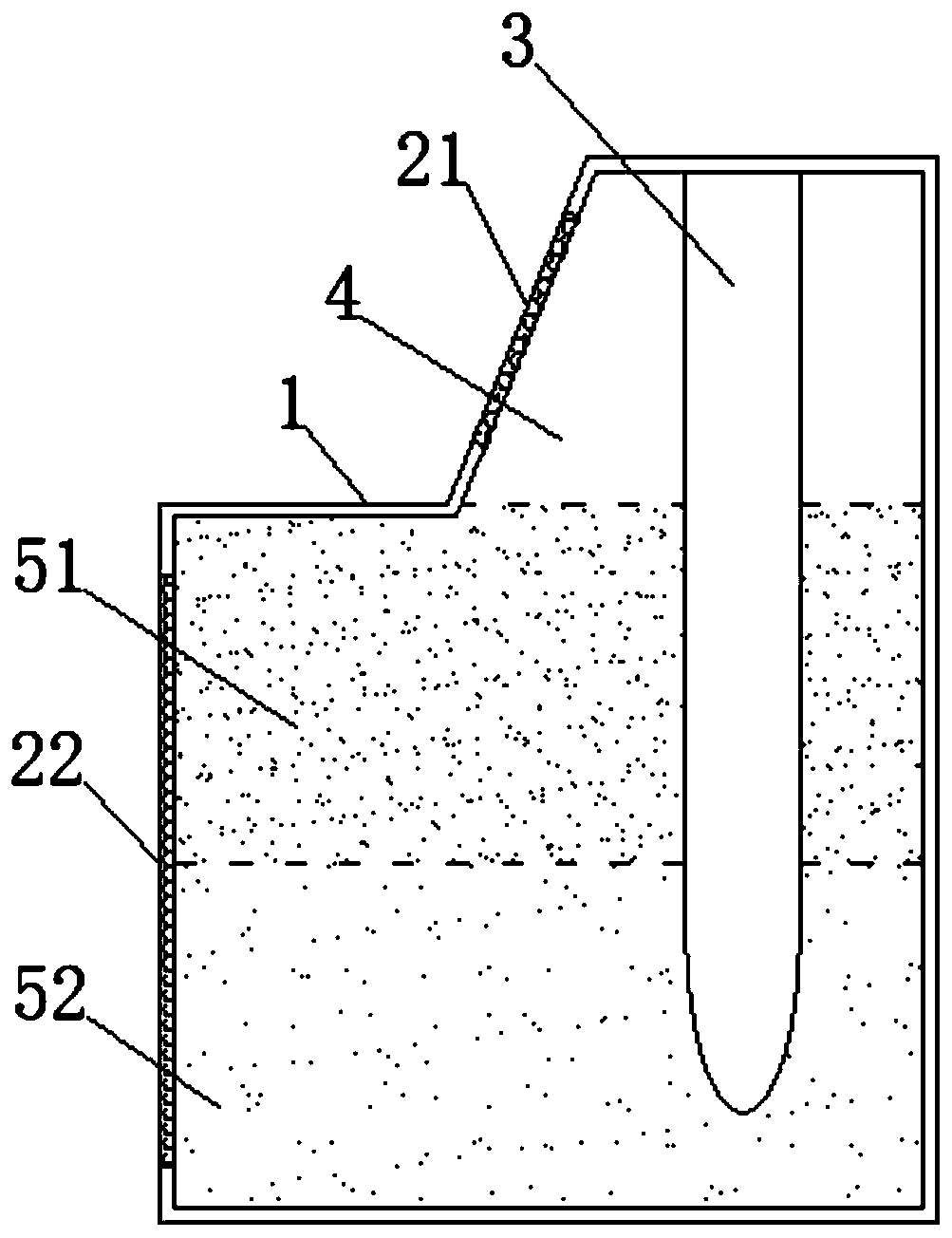

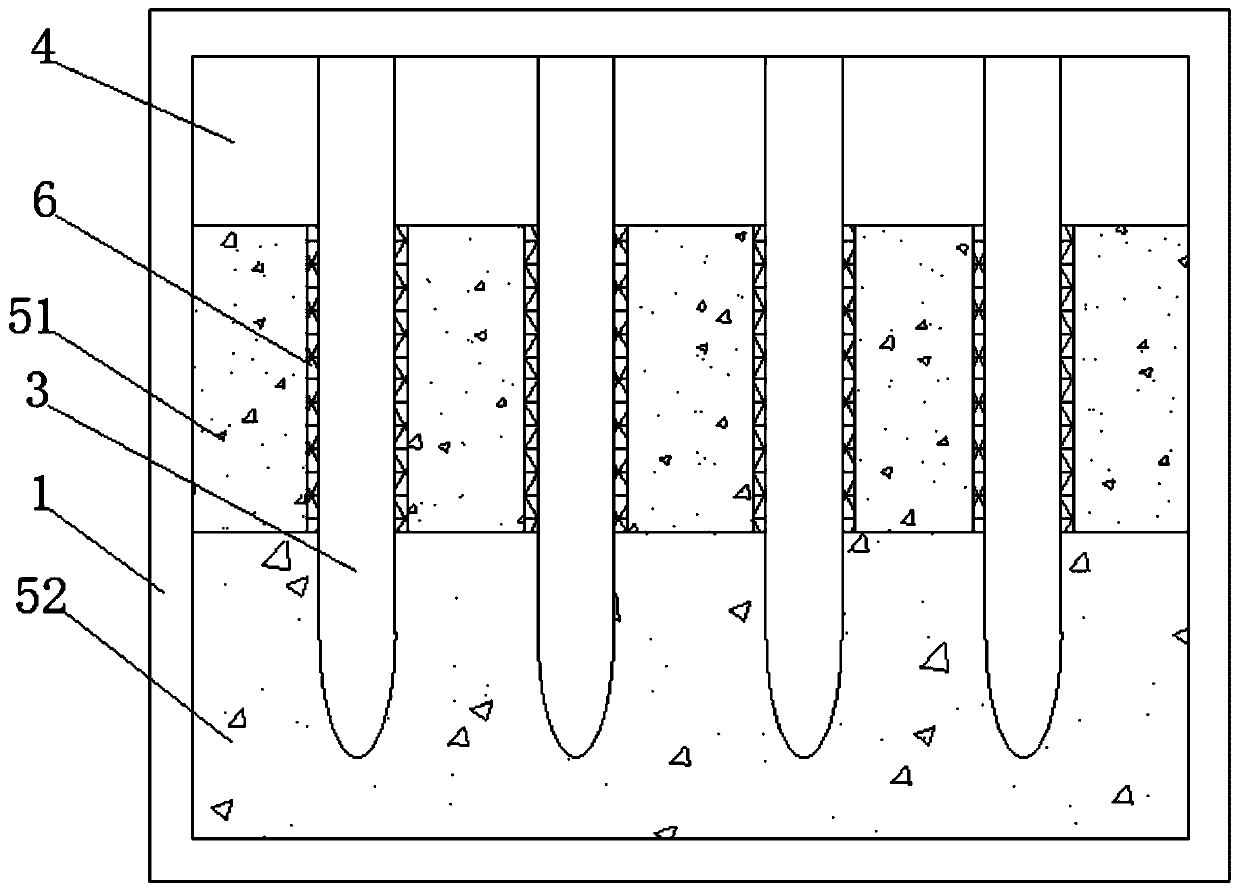

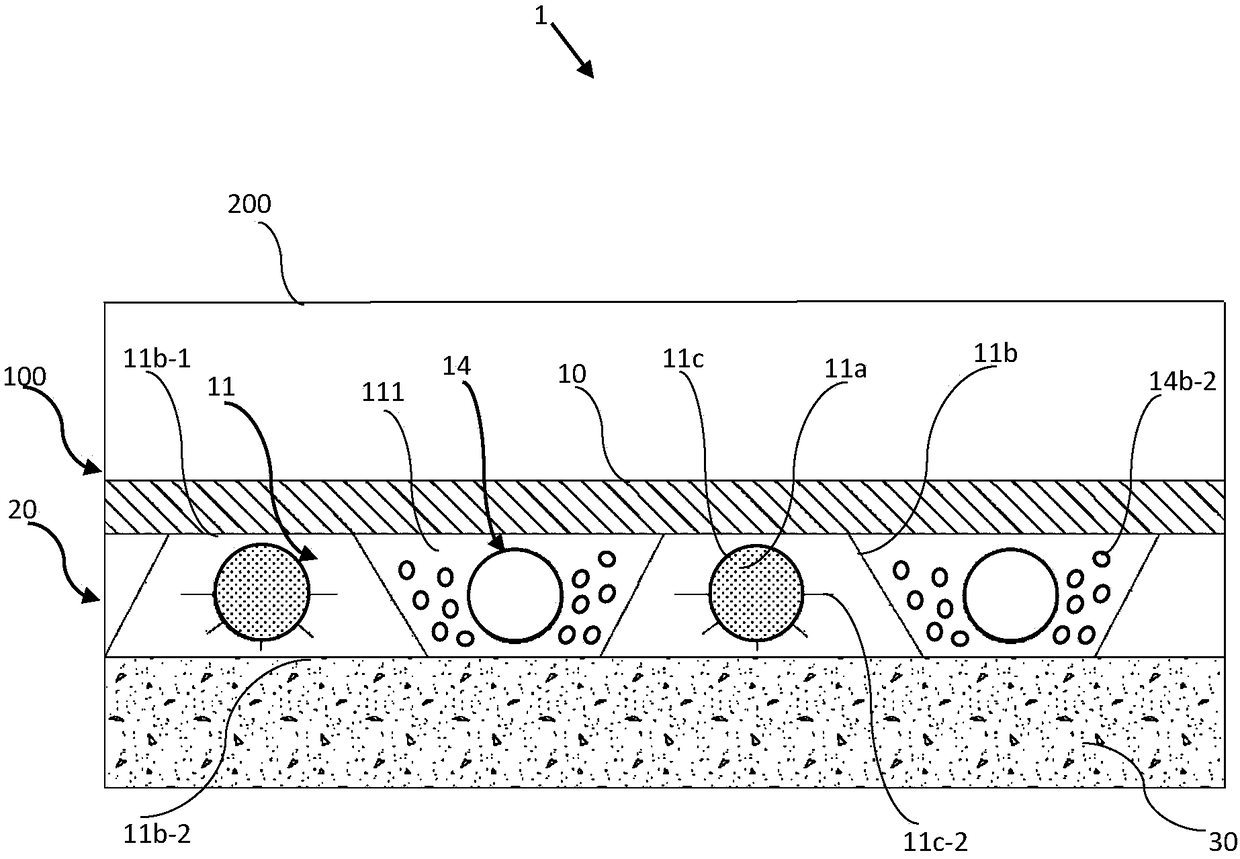

Capillary tube phase change insulation part, building wall comprising same and building

ActiveCN106351356ARapid cold storageFast heat storageWallsHeat storage plantsThermal insulationPhase-change material

The invention discloses a capillary tube phase change insulation part, a building wall comprising the same and a building. The capillary tube phase change insulation part is used for thermal insulation of the building wall and is characterized by comprising a phase change material, a phase change packaging body for packaging a phase change substance and a heat exchange part arranged in the phase change material, the heat exchange part and the phase change material perform contact heat exchange to adjust the temperature of the building wall, and the heat exchange part comprises at least one first capillary tube arranged in the phase change material.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

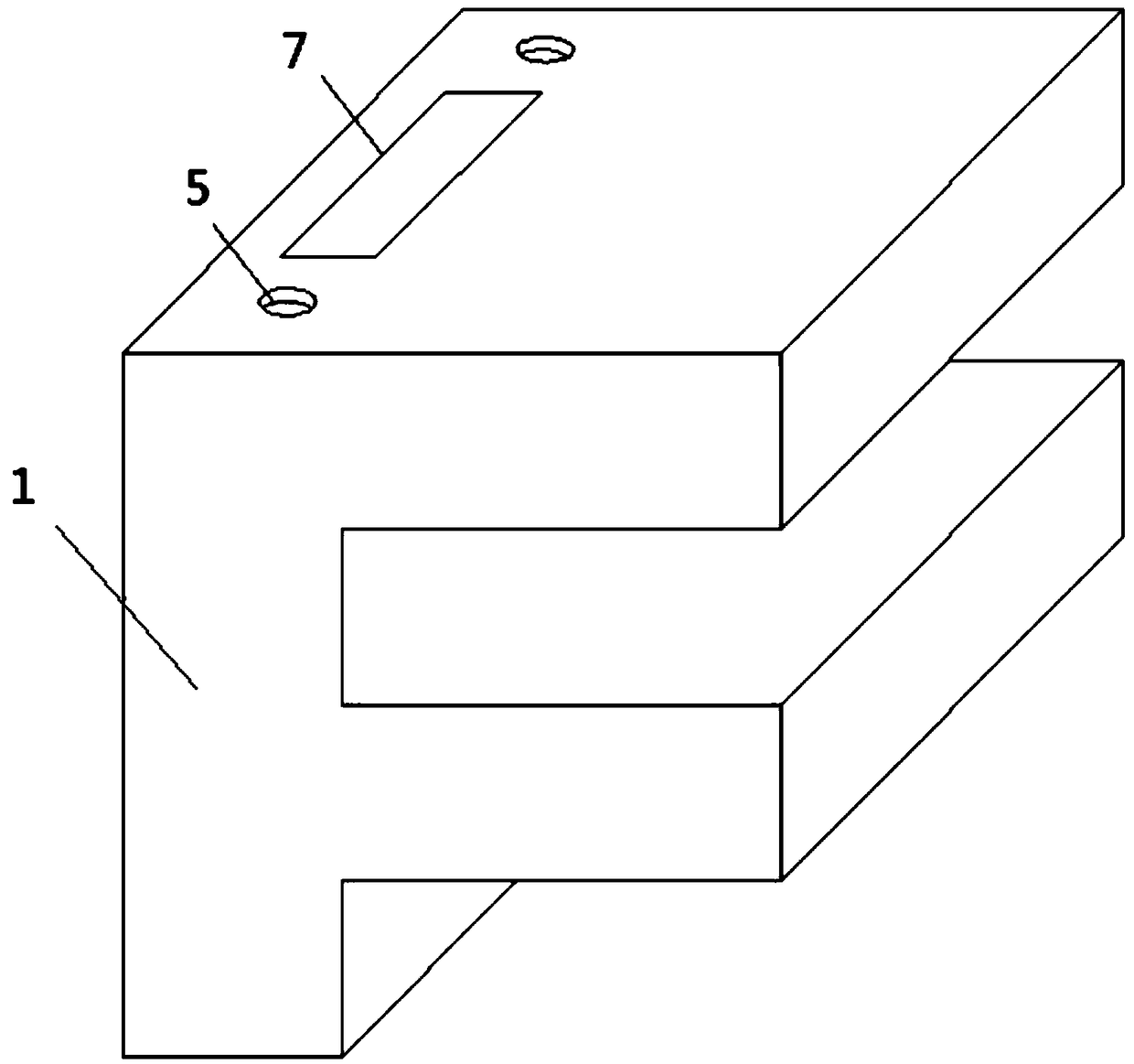

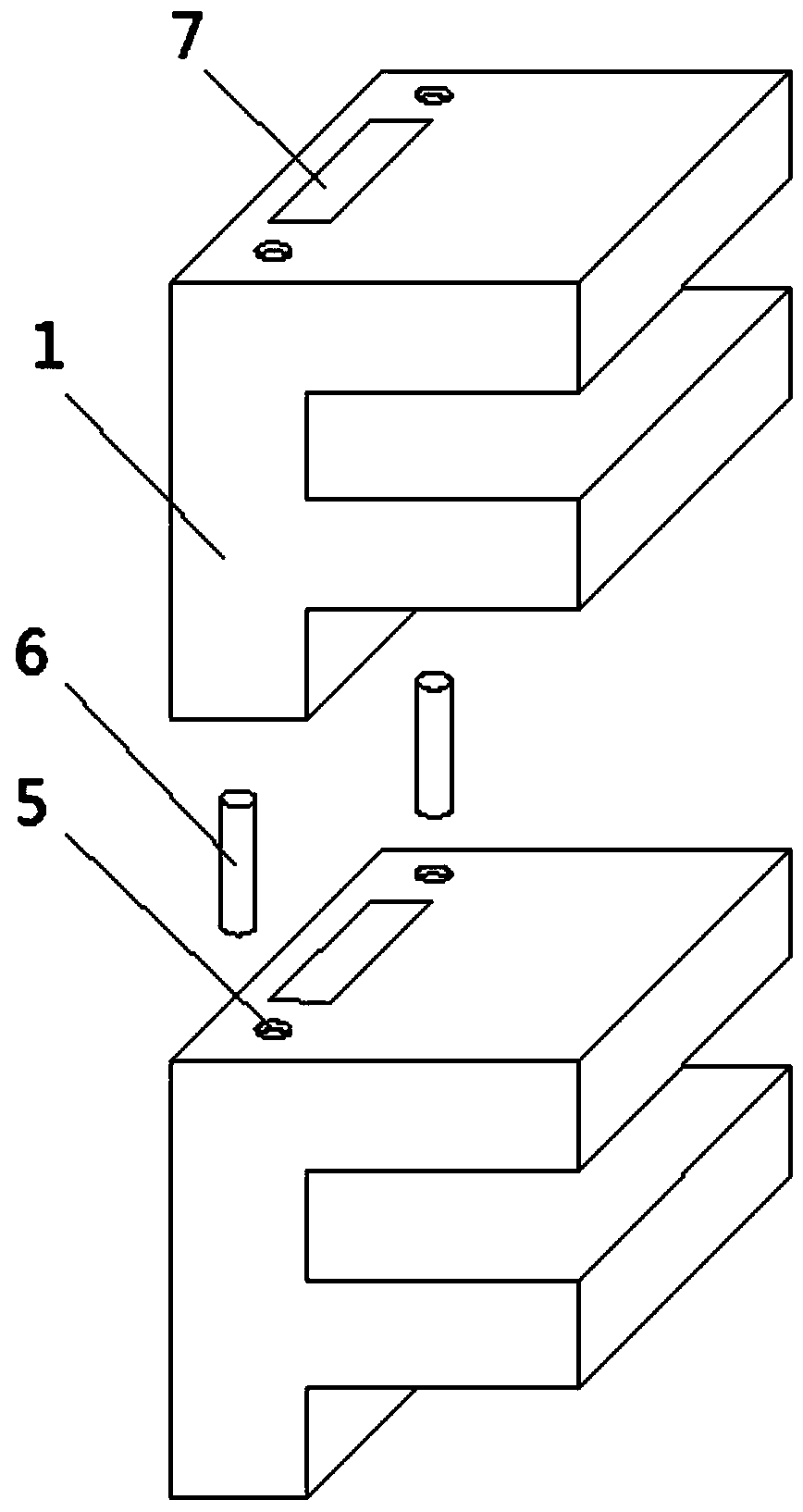

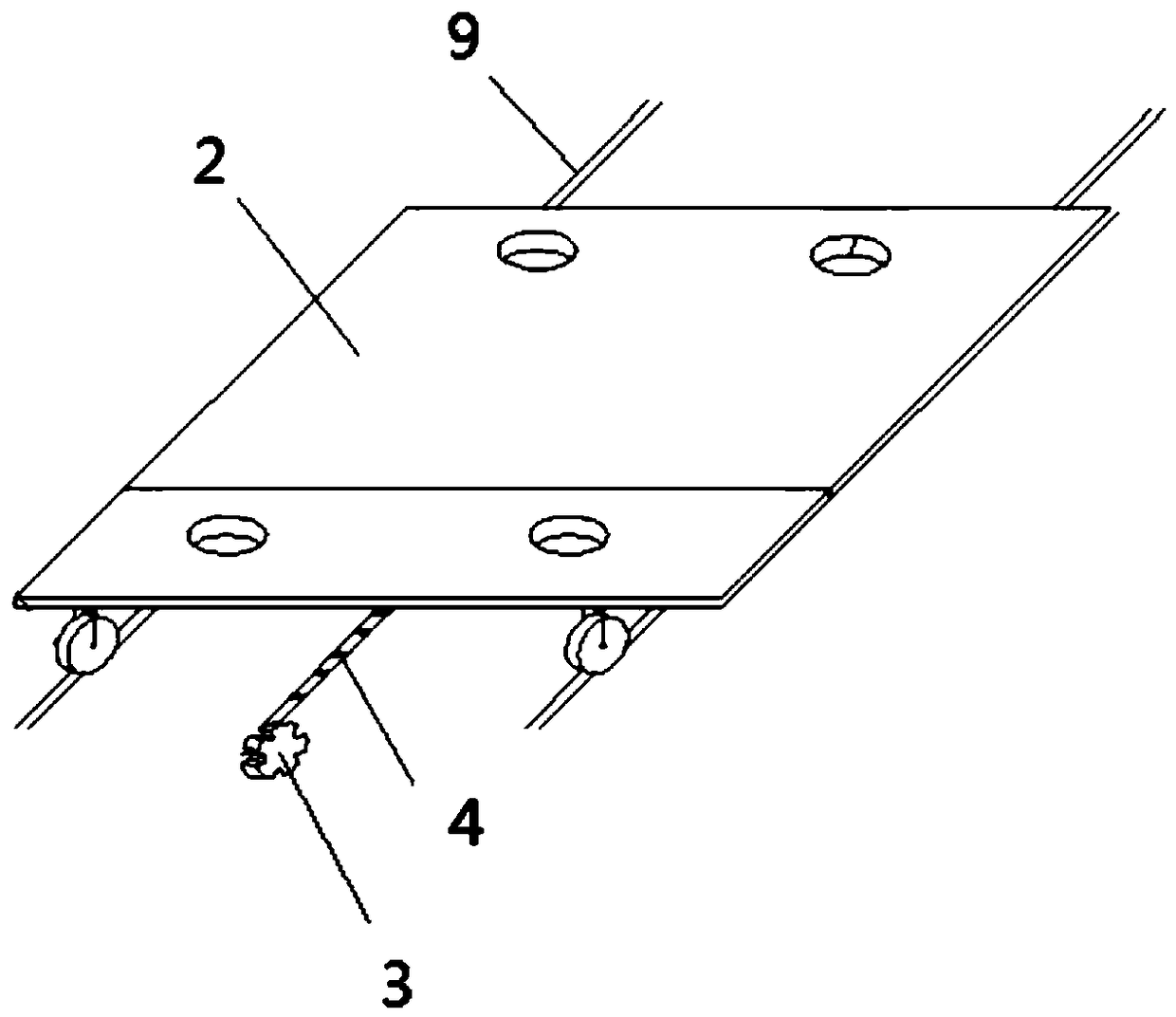

Solid heat storage device and application method

ActiveCN109029038AImprove distributionFast heat conductionHeat storage plantsProcess engineeringHeating energy

The invention discloses a solid heat storage device and an application method, and relates to the technical field of heat storage. The device comprises one or at least two heat storage units connectedwith each other; each heat storage unit comprises at least two heat storage blocks with concave-convex parts; the heat storage blocks of each heat storage unit are slidingly connected with each other, and are inserted through sliding of the concave-convex parts to form solid blocks without holes inside or are separated to form hollow blocks with size-variable through holes inside; and each heat storage block is provided with accommodating holes for accommodating heat sources. The device and the method can realize efficient heat storage and dissipation, and guarantees the utilization of heat energy to the greatest extent.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

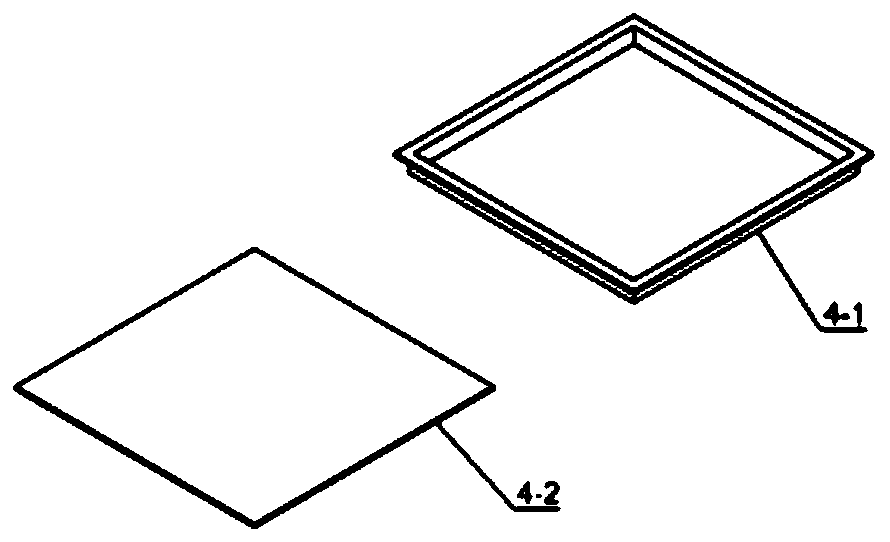

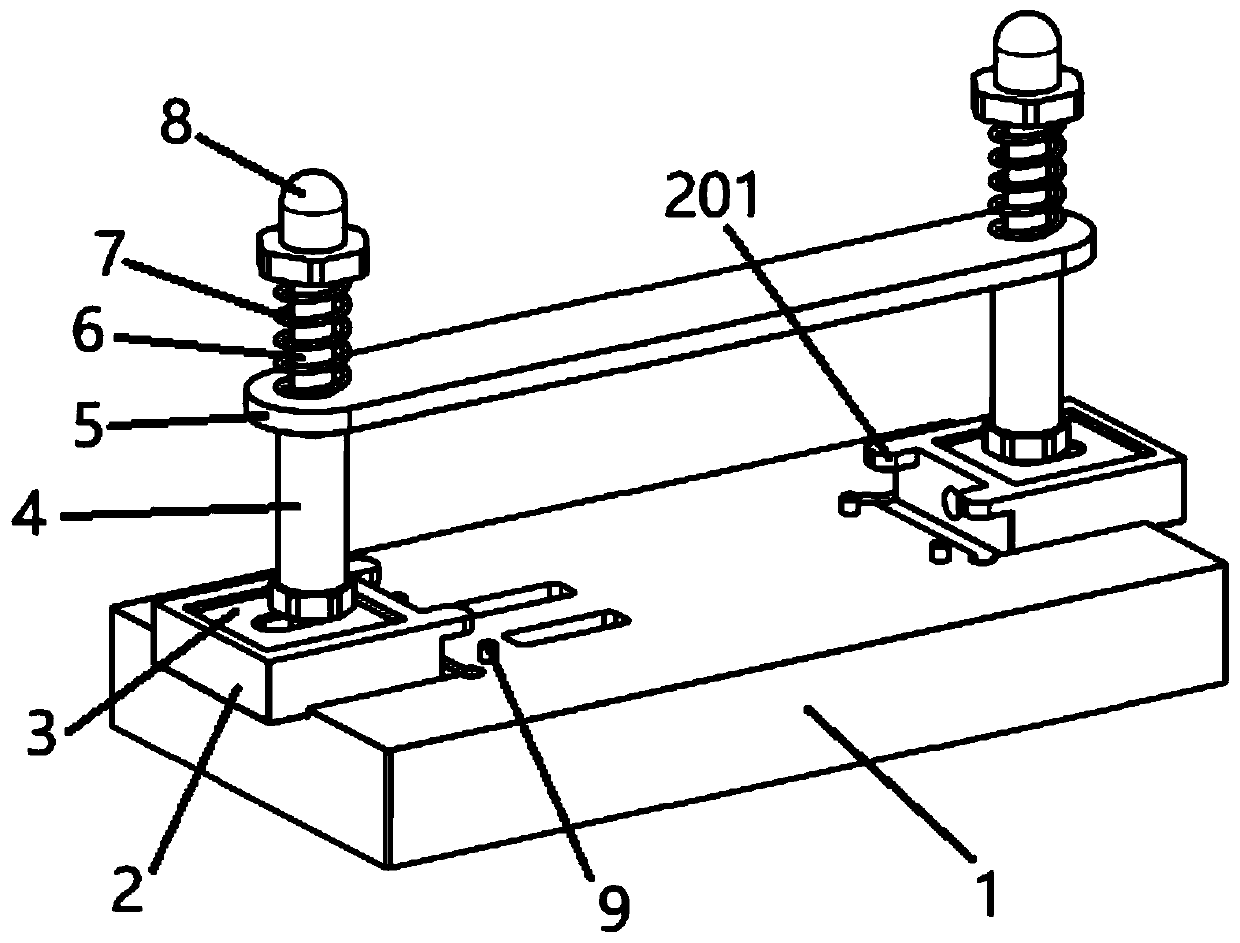

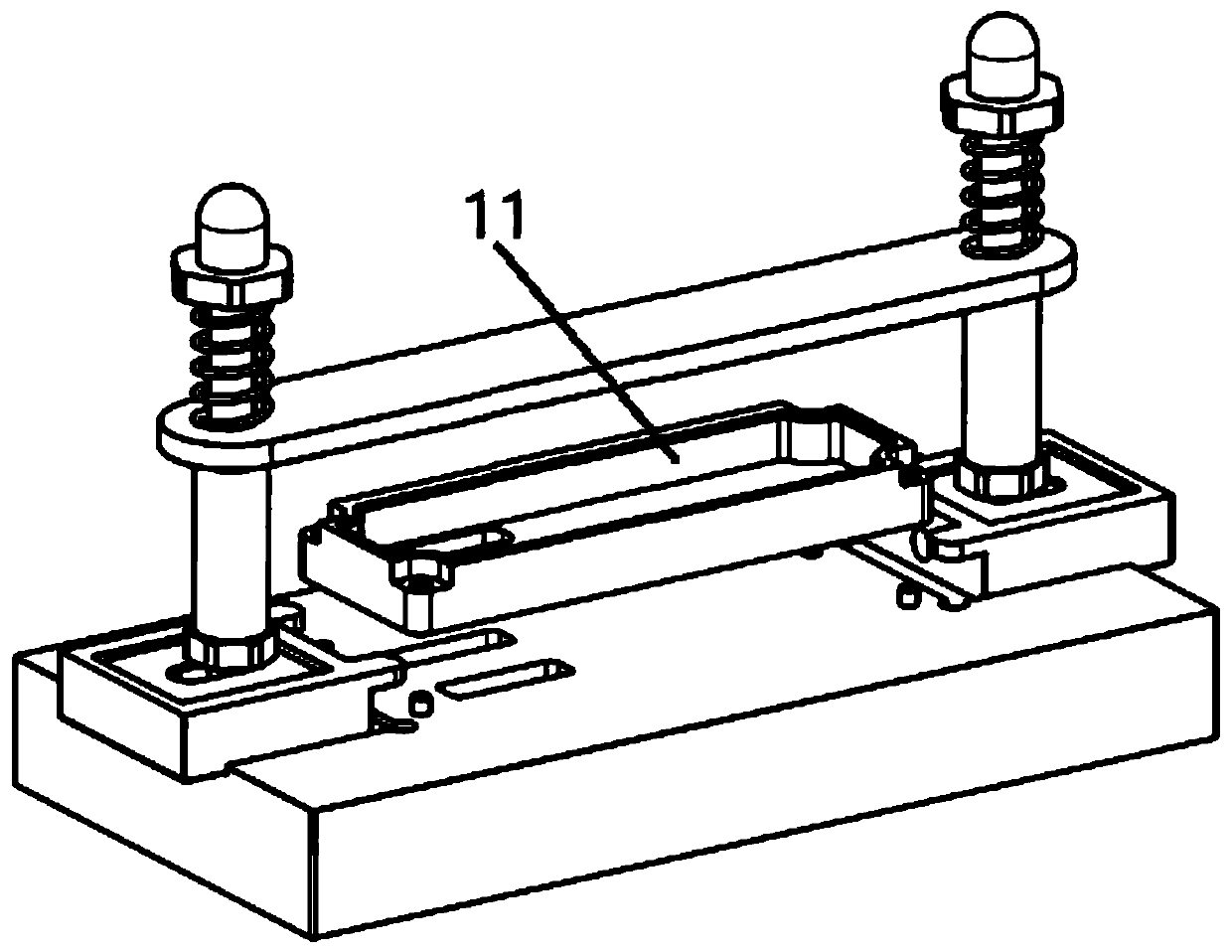

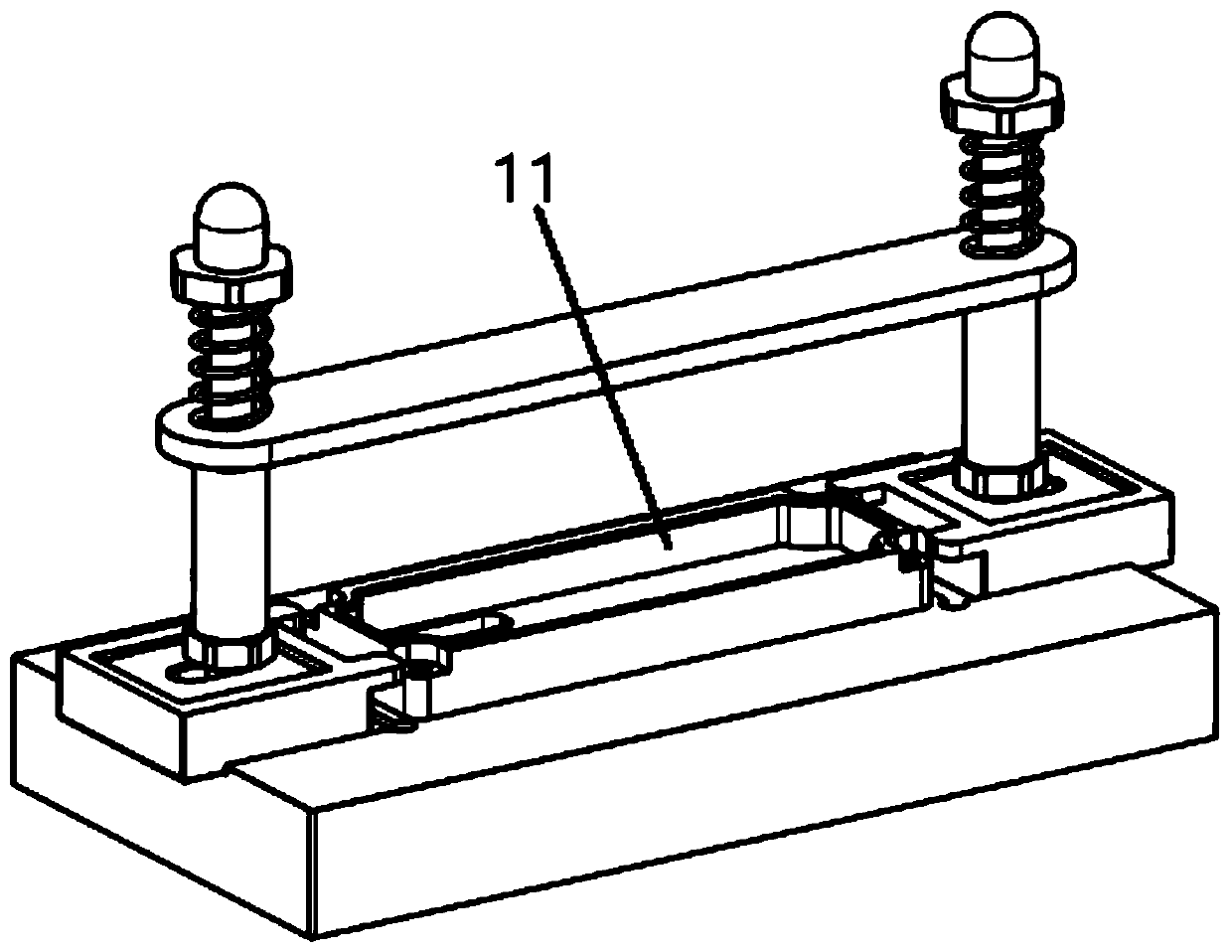

Reflow soldering clamping and positioning device of microwave assembly

PendingCN111097988AAccurate clamping and positioningReliable and precise wayPrinted circuitsMetal working apparatusReflow solderingEngineering

The invention discloses a reflow soldering clamping and positioning device of a microwave assembly. The microwave assembly comprises a shell and a circuit board, wherein the clamping and positioning device comprises a base, a plurality of positioning parts, at least two shell pressing assemblies and a circuit board pressing block assembly. Each positioning part is arranged on the base, and the positioning parts are used for positioning the relative position of the shell on the base; each shell pressing assembly is connected with the base, and the shell pressing assemblies are used for pressingthe shell on the base; and the circuit board pressing block assembly is connected with the base and used for pressing the circuit board on the shell. The reflow soldering clamping and positioning device of the microwave assembly can conveniently, quickly and accurately position and clamp the microwave assembly, and solves the technical problem in the prior art that the reflow soldering clamping and positioning device is not suitable for the microwave assembly containing the printed board or a microstrip board, the shell and electronic components.

Owner:SHANGHAI SPACEFLIGHT ELECTRONICS & COMM EQUIP RES INST

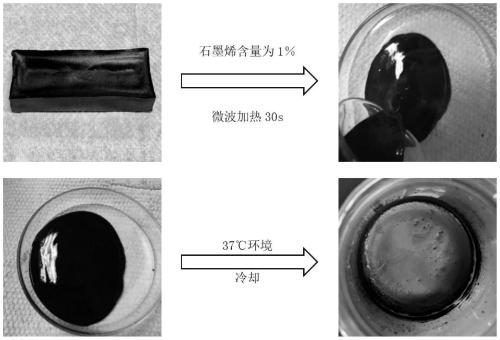

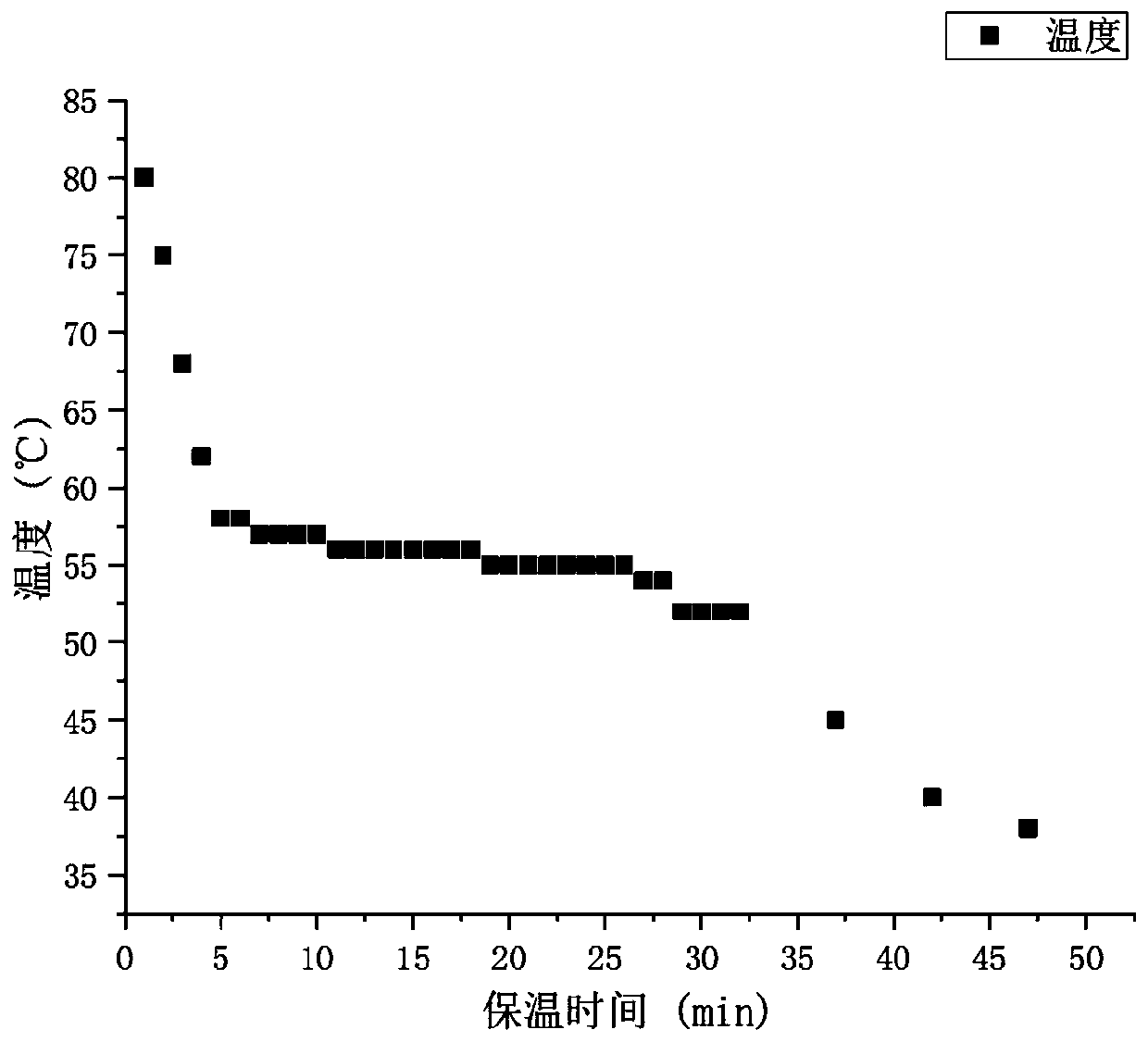

Warm bag

The invention discloses a warm bag. The warm bag comprises an inner container, and the interior of the inner container is provided with a paraffin / graphene composite phase-change material; and heat preservation energy storage is realized by microwave heating. According to the warm bag provided by the invention, the composite phase-change material arranged in the inner container is subjected to heat storage by microwaves, the composite phase-change material is heated uniformly, the heating time is short and only a few minutes or even tens of seconds, so that the warm bag is convenient for a user to use, can be reused for a plurality of times, and has wide application prospects.

Owner:XI AN JIAOTONG UNIV

Phase-change heat-storage-type salt water desalting device based on diurnal temperature variation and using method

InactiveCN109305708AEasy to collectIncrease condensation areaGeneral water supply conservationSeawater treatmentThermal energyWater storage tank

The invention discloses a phase-change heat-storage-type salt water desalting device based on a diurnal temperature variation and a using method. The phase-change heat-storage-type salt water desalting device comprises a water supplying device, a phase-change heat storage device, a sleeve and a water storage tank. The phase-change heat storage device is a solar energy heat collection and storage device which uses a phase-change material as a heat storage working medium. A salt water desalting method comprises the following steps: while receiving illumination at daytime, converting solar energyto heat energy for storing by the phase-change material; at night, salt water to be processed is heated to a certain temperature through a copper pipe in the heat storage device and flows into an inner pipe of the sleeve, part of the heated salt water is evaporated into water vapor, is condensed when encountering the inner wall of the outer pipe with a low temperature and is converged in the outer pipe, then flows to the water storage tank through the outer pipe. The heat storage device can store a large amount of heat and heat the salt water to the higher temperature. The salt water of whichthe temperature is reduced can be reflowed and reheated, so that a purpose of maximally using the heat is achieved. The device is capable of, through developing an efficient photo-thermal conversionphase-change heat storage material, improving a solar radiation utilization ratio, and reducing energy consumption for unit fresh water.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

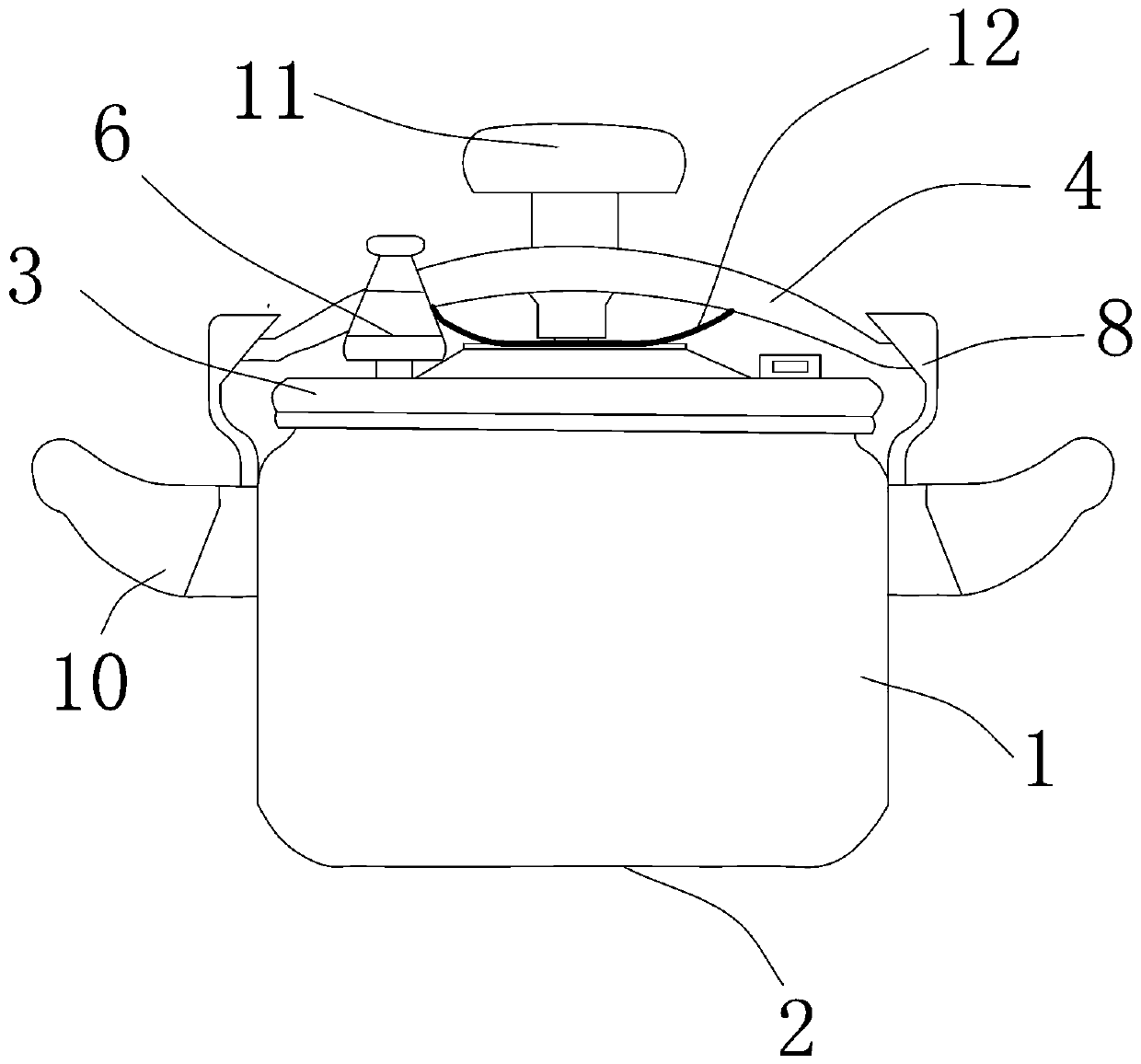

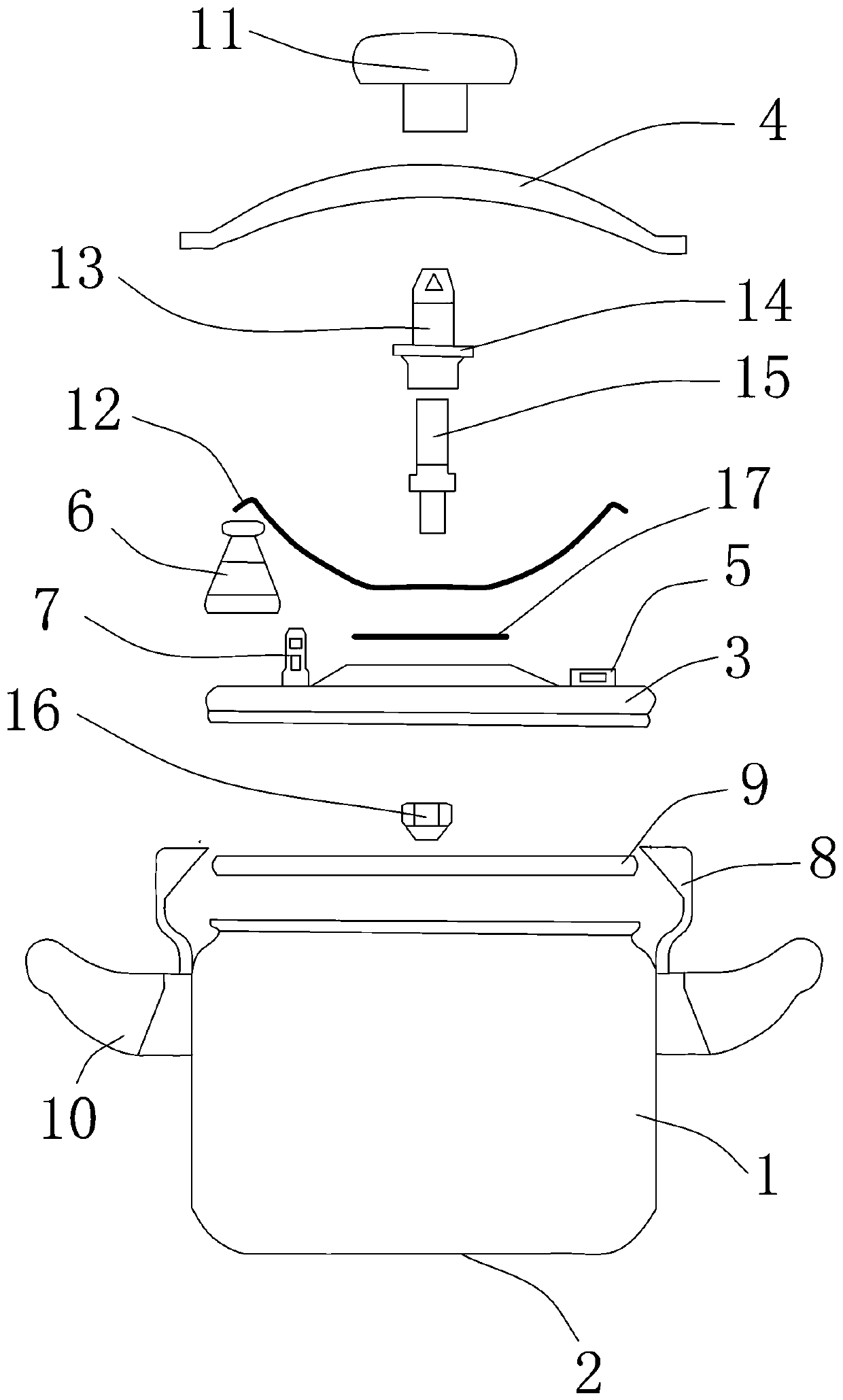

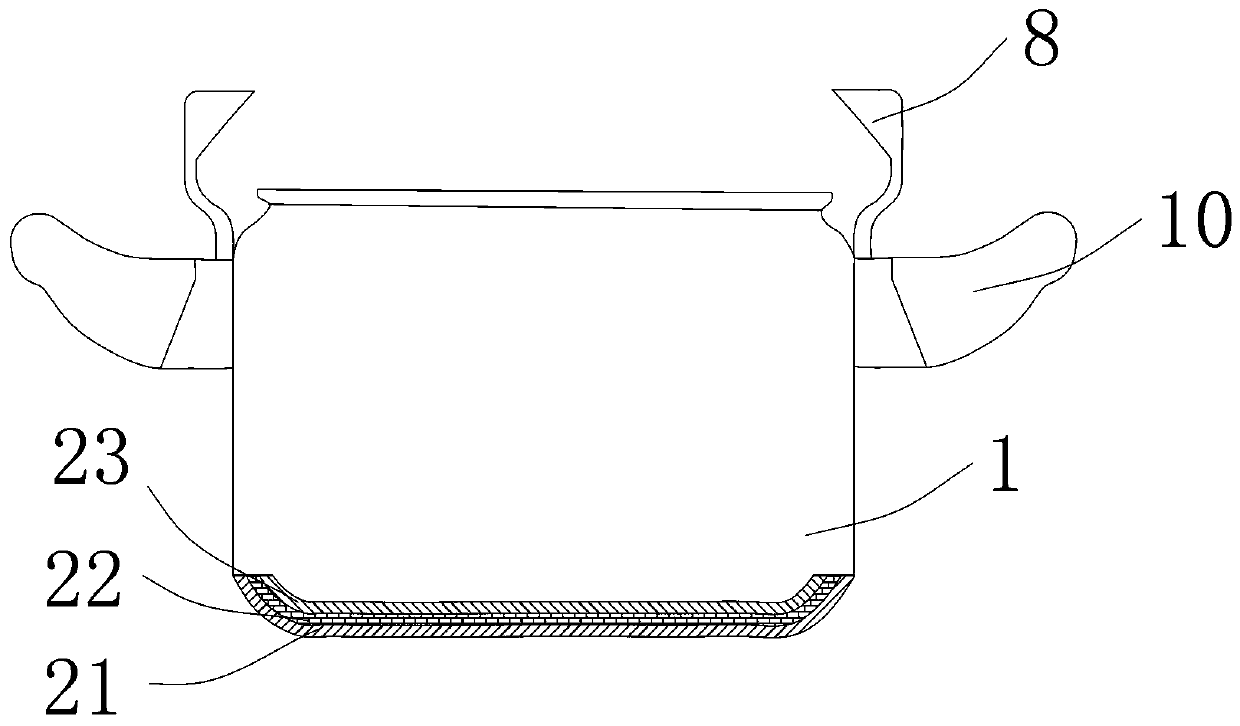

Gland type safety pressure cooker

InactiveCN111110024AGood adhesionFast heat conductionCooking-vessel materialsPressure-cookersRelief valveComposite structure

The invention discloses a gland type safety pressure cooker which comprises a pot body, a pot cover and a pot bottom. The pot body and the pot bottom are of an integrated structure. The pot bottom isof a three-layer composite structure, and comprises a magnetic stainless steel outer layer, an aluminum interlayer and a food-grade 304 stainless steel inner layer. The pot cover is provided with a pressing and holding beam, an opening and closing locking device, a safety valve, a pressure limiting valve and an exhaust pipe. The pressing and holding beam is fixed on the pot cover through the opening and closing locking device. Pot lugs used for buckling the two ends of the pressing and holding beam are arranged on the two sides of the pot body respectively. A circle of groove is formed in theperiphery of the bottom face of the pot cover, and a sealing ring is placed in the groove. The three-layer composite pot bottom is durable, fast in heat conduction, even in heating, suitable for various stoves such as gas stoves and induction cookers and good in universality. The sealing ring with a U-shaped or V-shaped section is good in sealing performance. The pot cover with the pressing and holding beam, the pressure limiting valve and the safety valve is good in anti-explosion performance, the situation of pot frying is avoided, and the safety performance is high. The pot lugs are of highstrength and are provided with blocking pieces. The pressing and holding beam cannot be displaced to leak air.

Owner:GUANGDONG SHUNFA HARDWARE PRODS

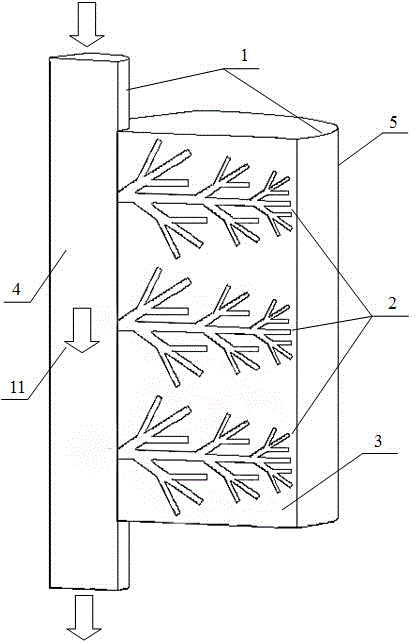

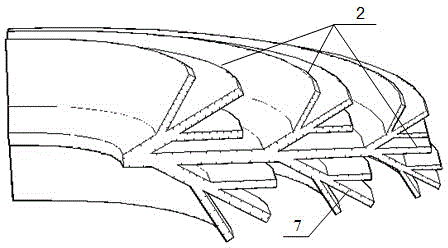

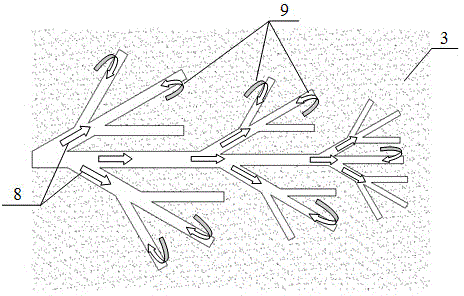

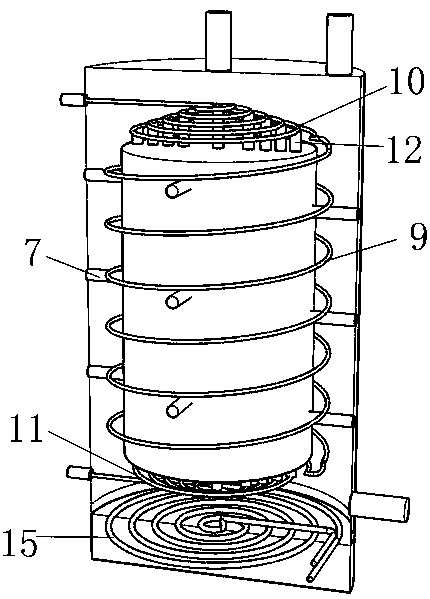

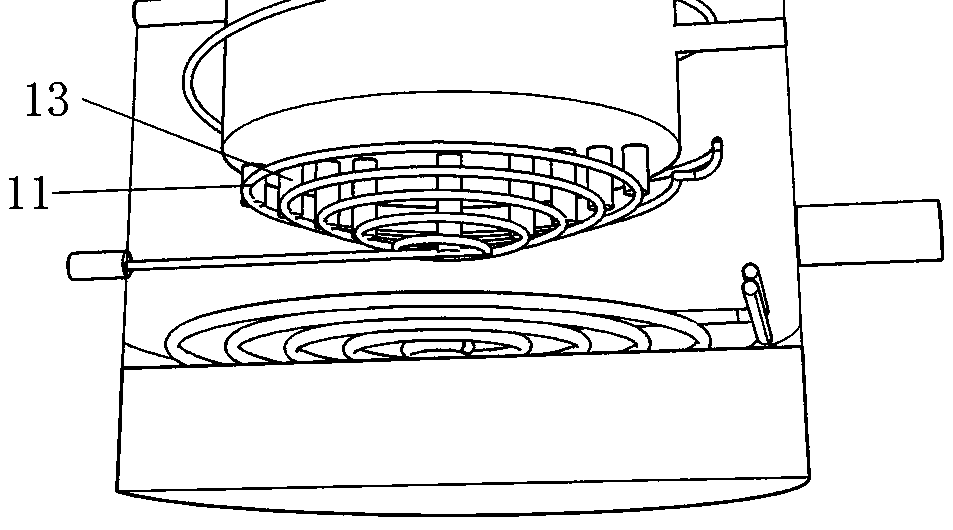

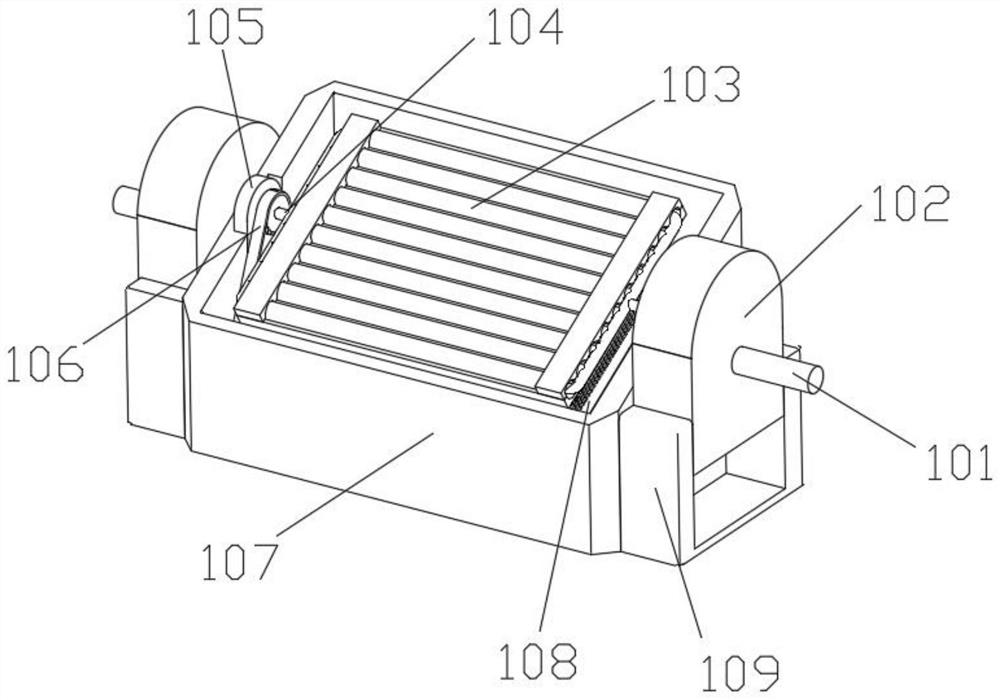

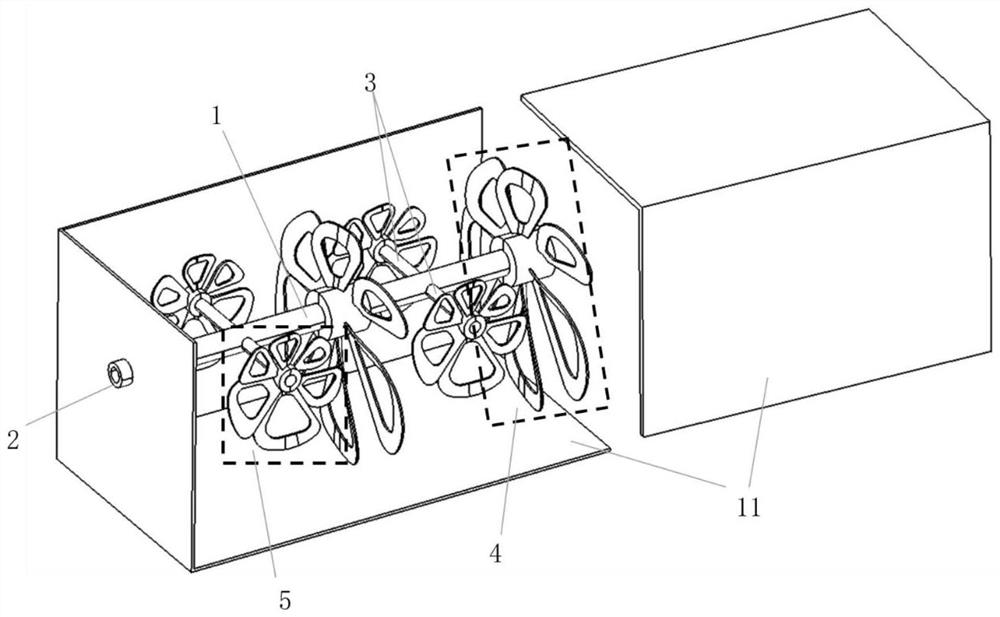

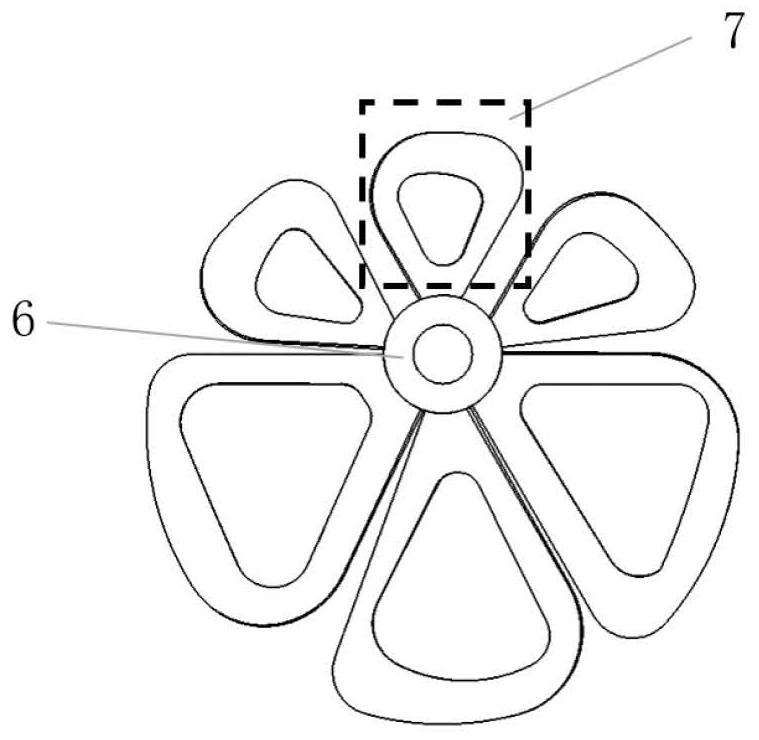

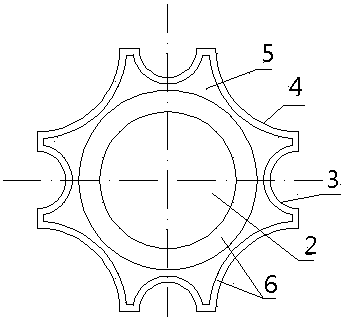

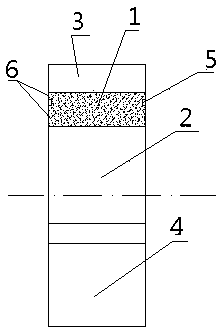

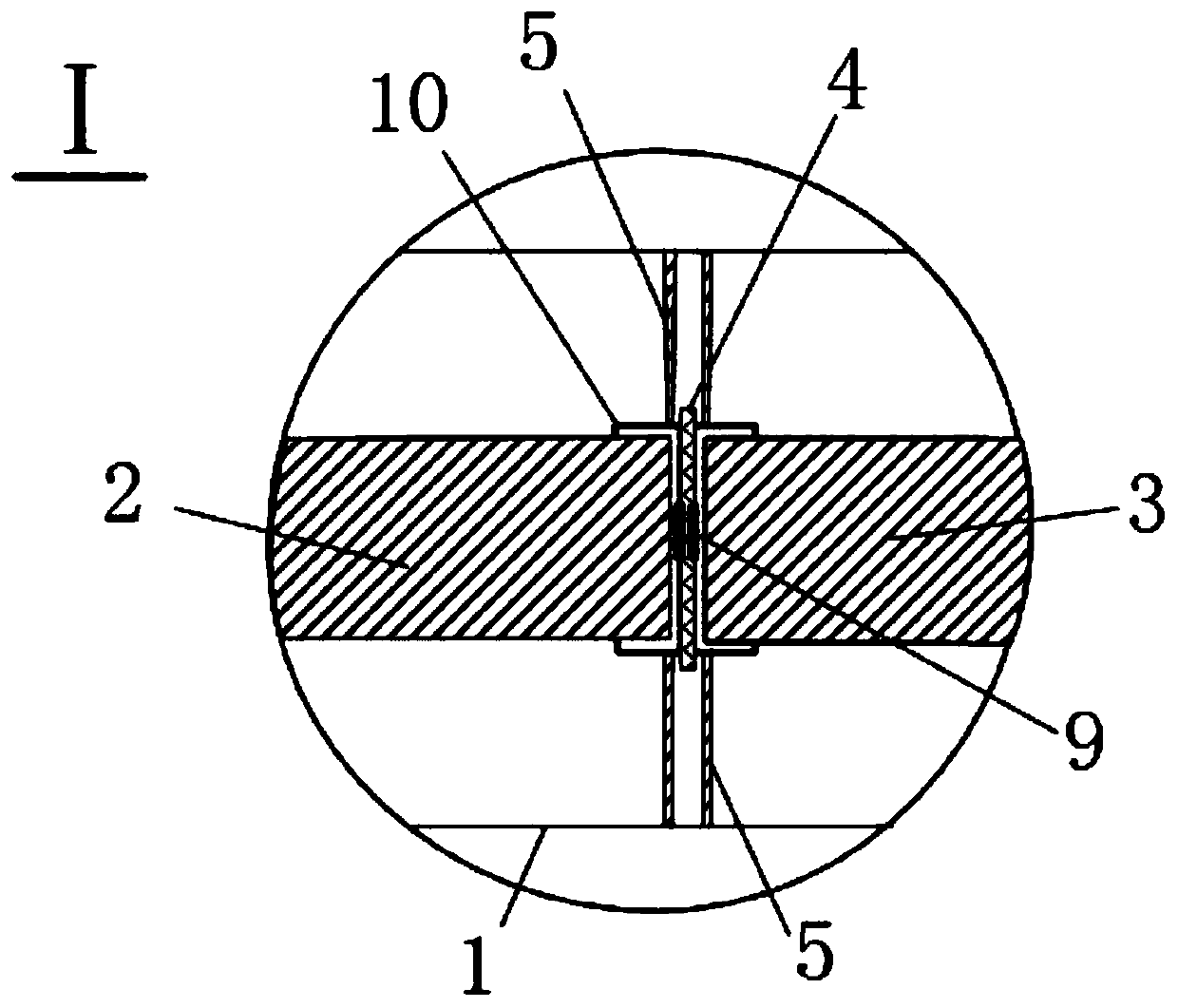

Disturbance mixing rapid heat storage module

The invention relates to a disturbance mixing rapid heat storage module which comprises a central columnar steam cavity, branch rod steam cavities, axial fan blade type fins, radial fan blade type fins and a phase change container. The central columnar steam cavity is arranged in the phase change container and is connected with the phase change container through a framework rotatable support. The branch rod steam cavities communicate with the interior of the central columnar steam cavity, and are symmetrically distributed along the radial direction of the central columnar steam cavity. The axial fan blade type fins and the radial fan blade type fins are each of an eccentric fan blade structure composed of a plurality of blade cavity ribs different in size and are in clearance fit with the outer surface of the center columnar steam cavity and the outer surfaces of the branch rod steam cavities respectively. Under the action of external impact or disturbance, due to center-of-gravity shift, working media in the phase change container can be promoted to be mixed in the axial direction and the radial direction respectively. The central columnar steam cavity, a plurality of groups of axial fan blade type fins and a plurality of groups of radial fan blade type fins are arranged in the phase change container, and other parts of the phase change container are filled with phase change working media with heat absorption and heat release functions.

Owner:XI AN JIAOTONG UNIV

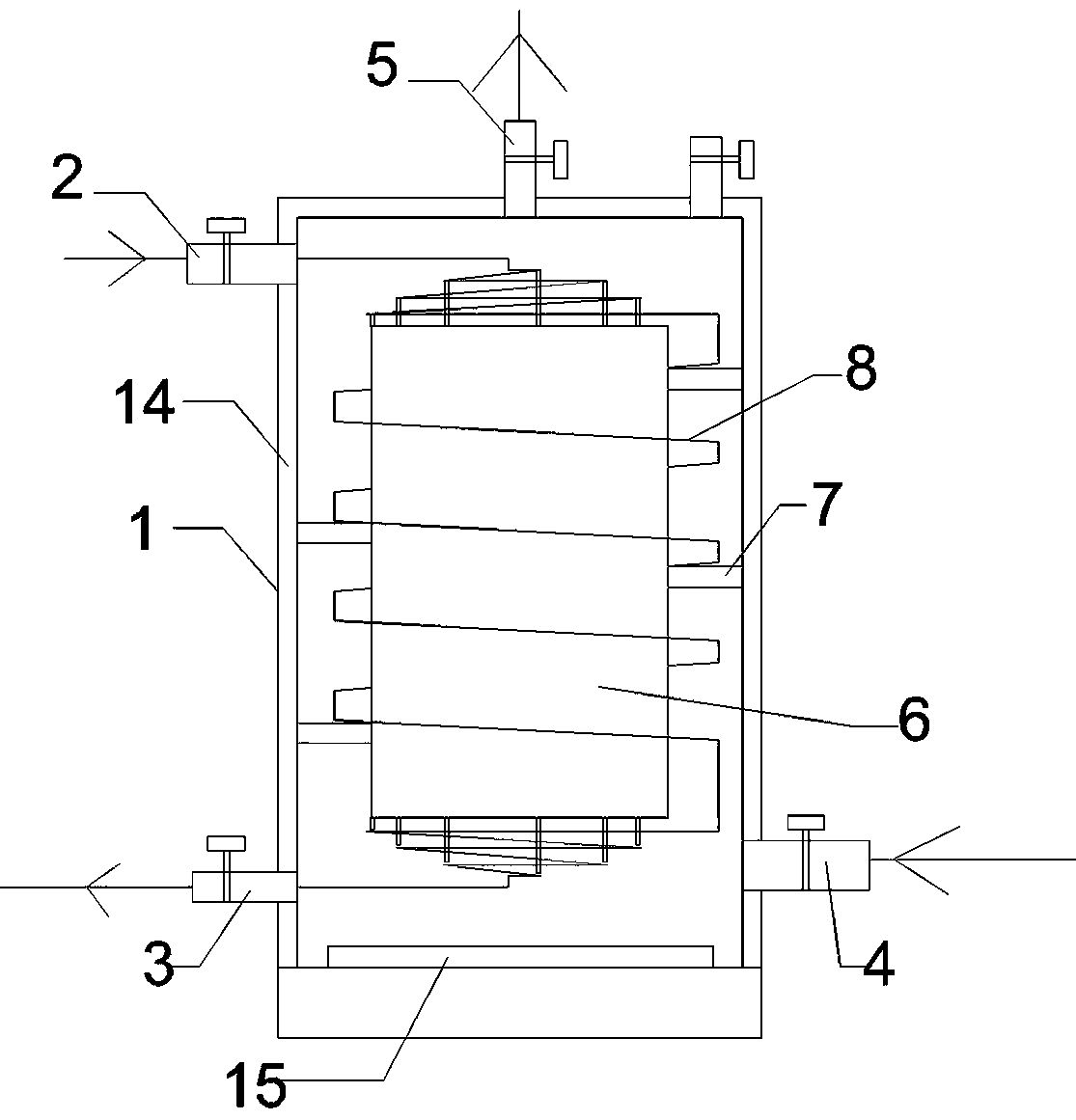

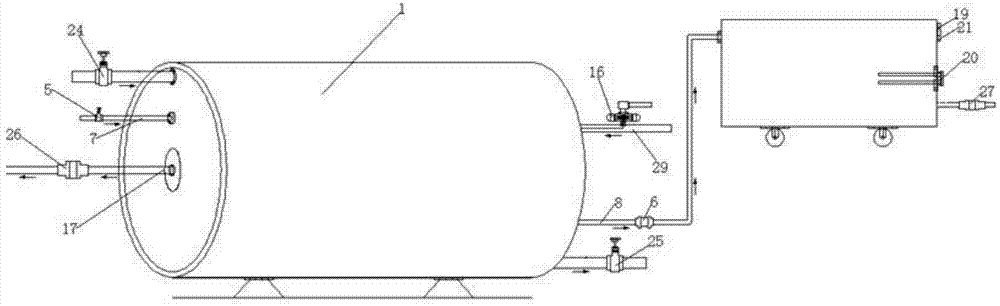

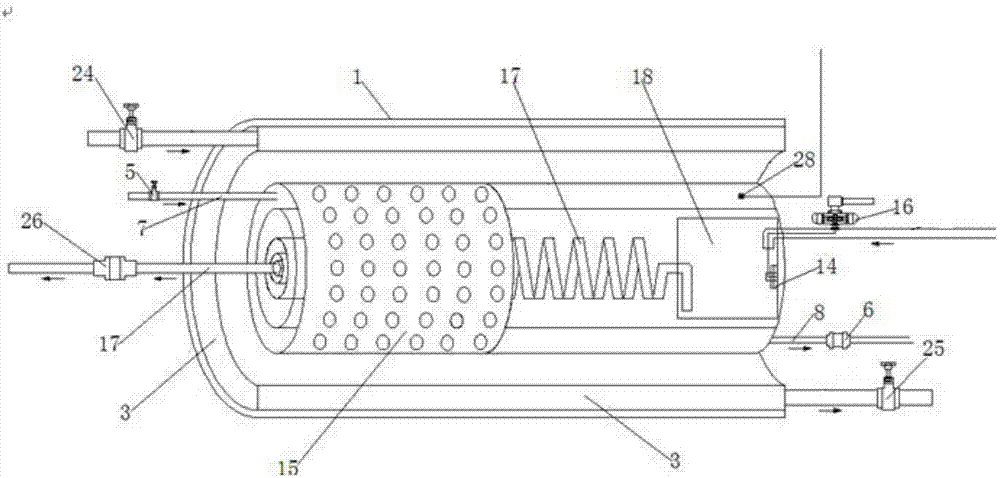

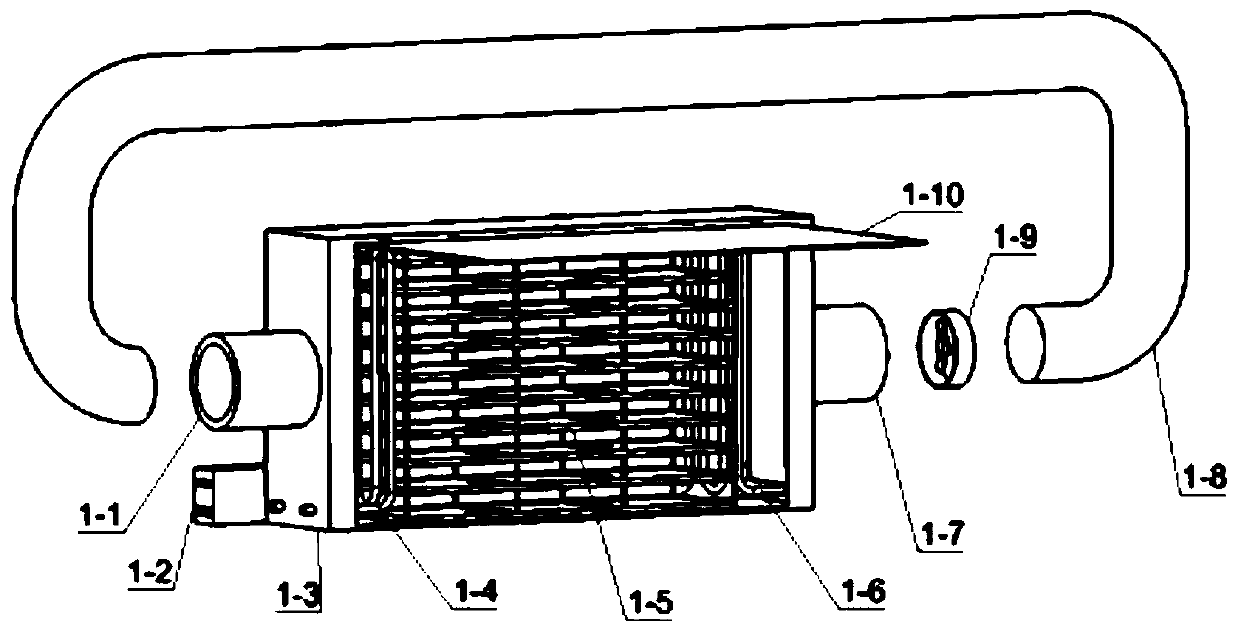

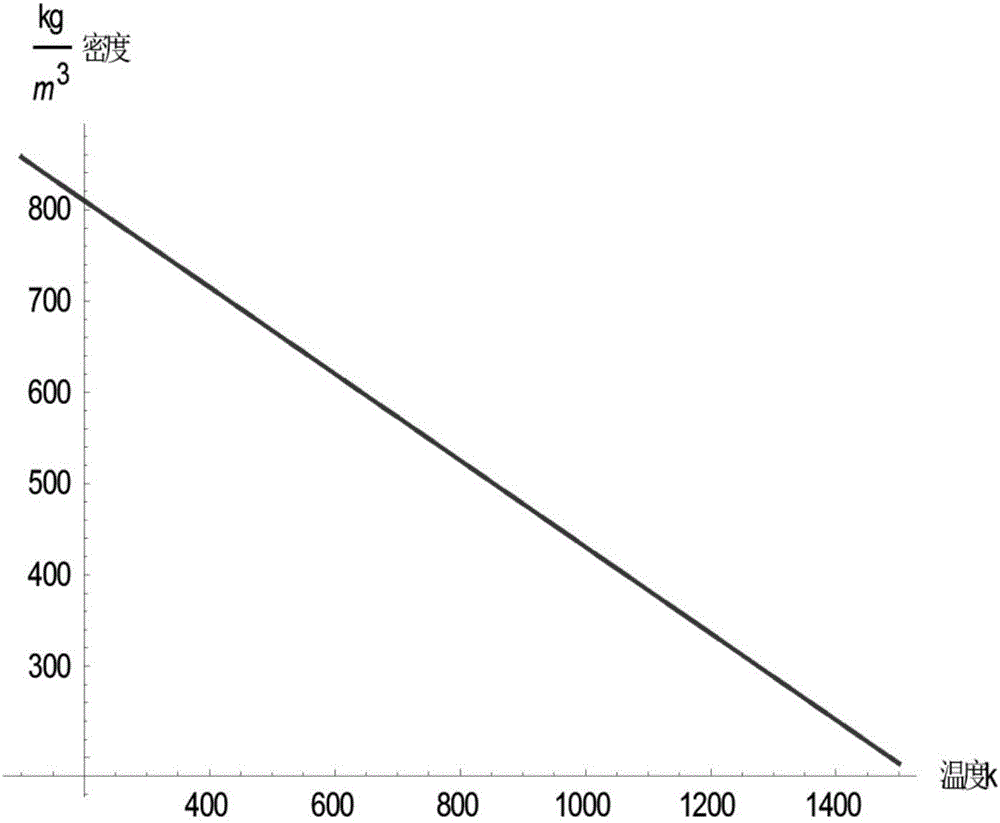

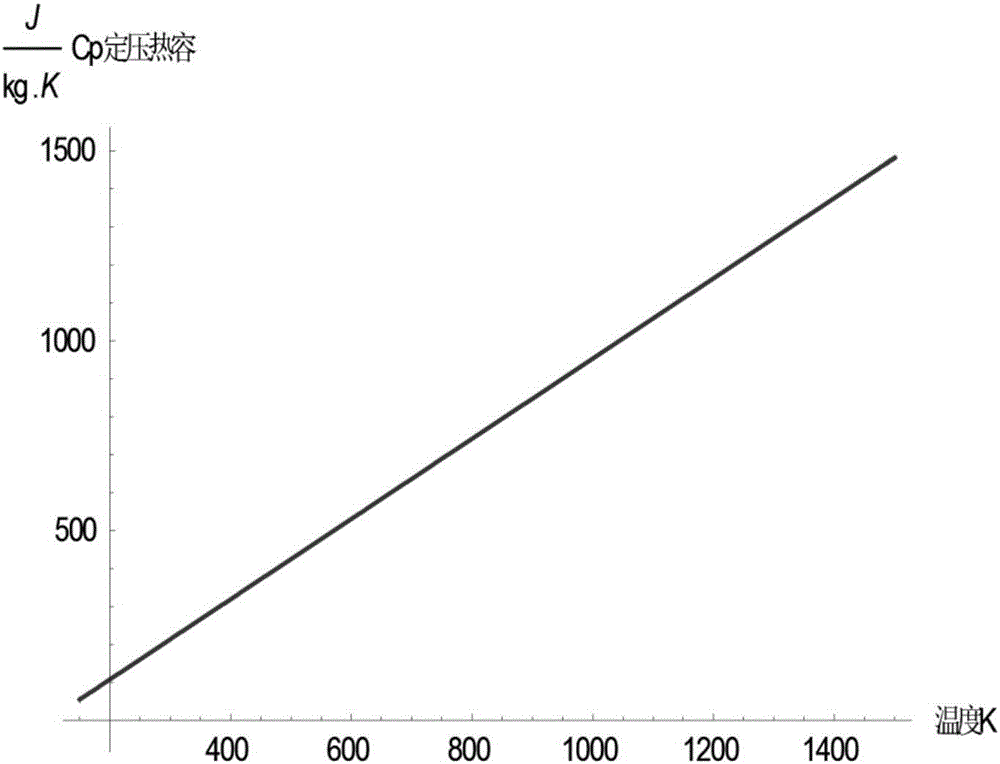

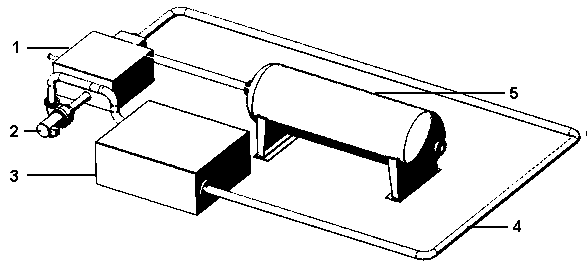

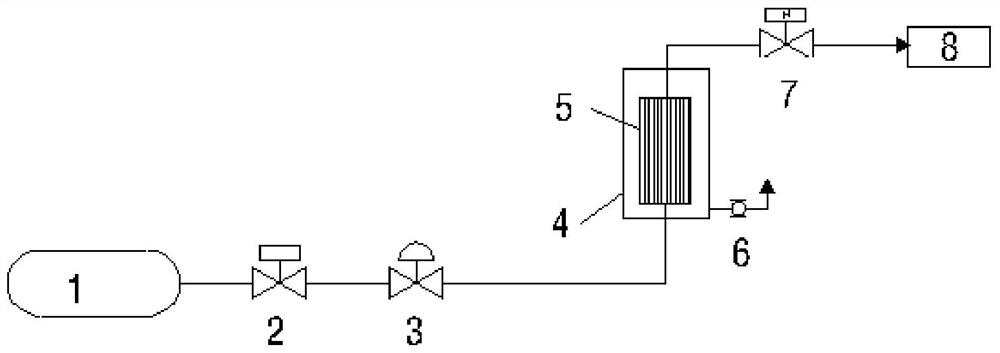

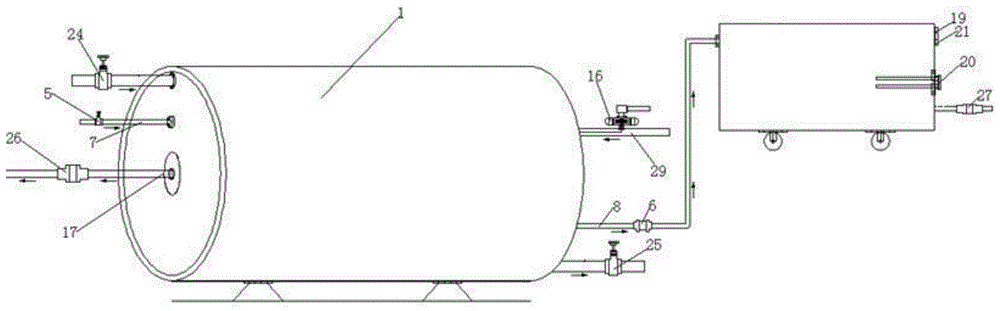

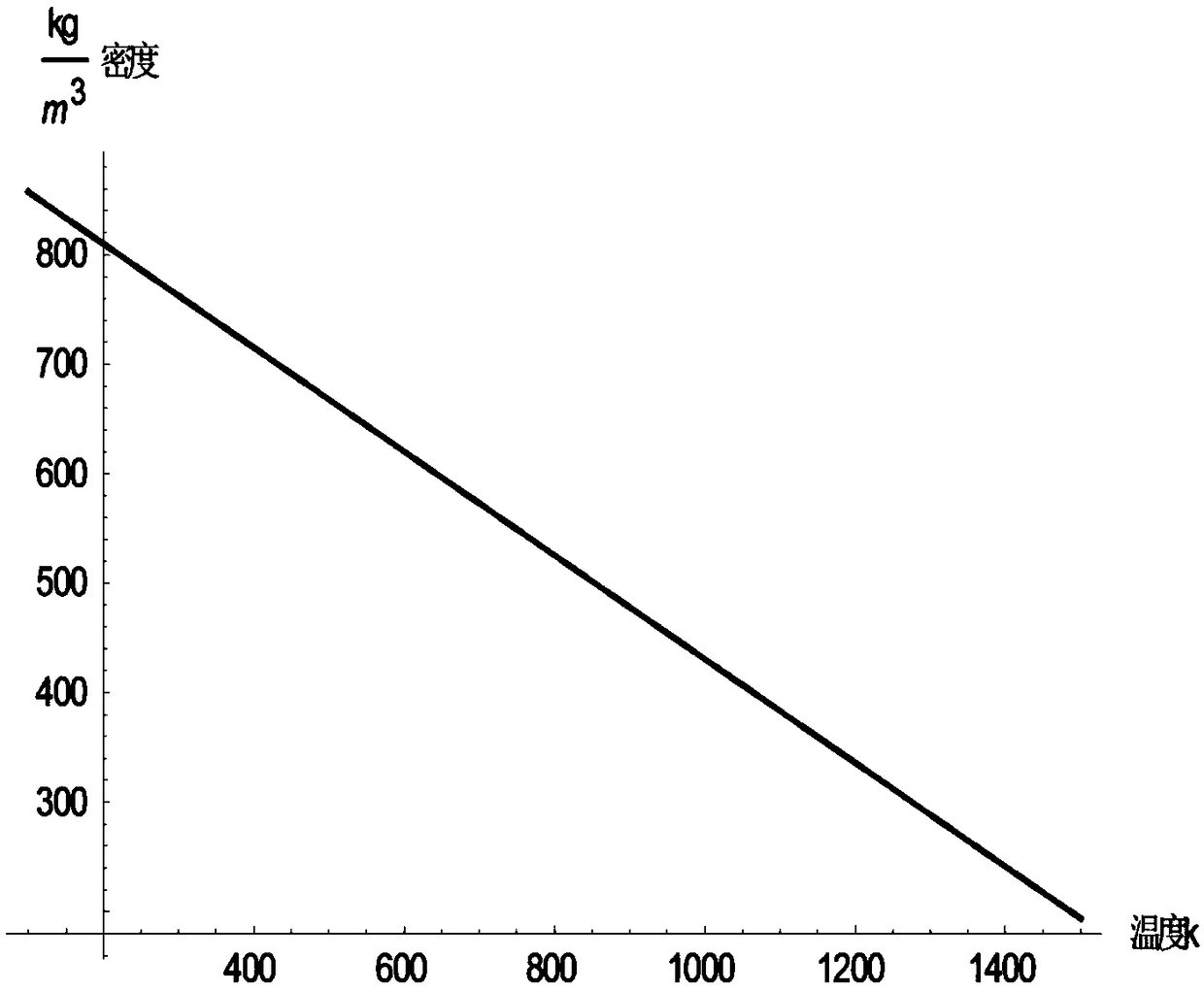

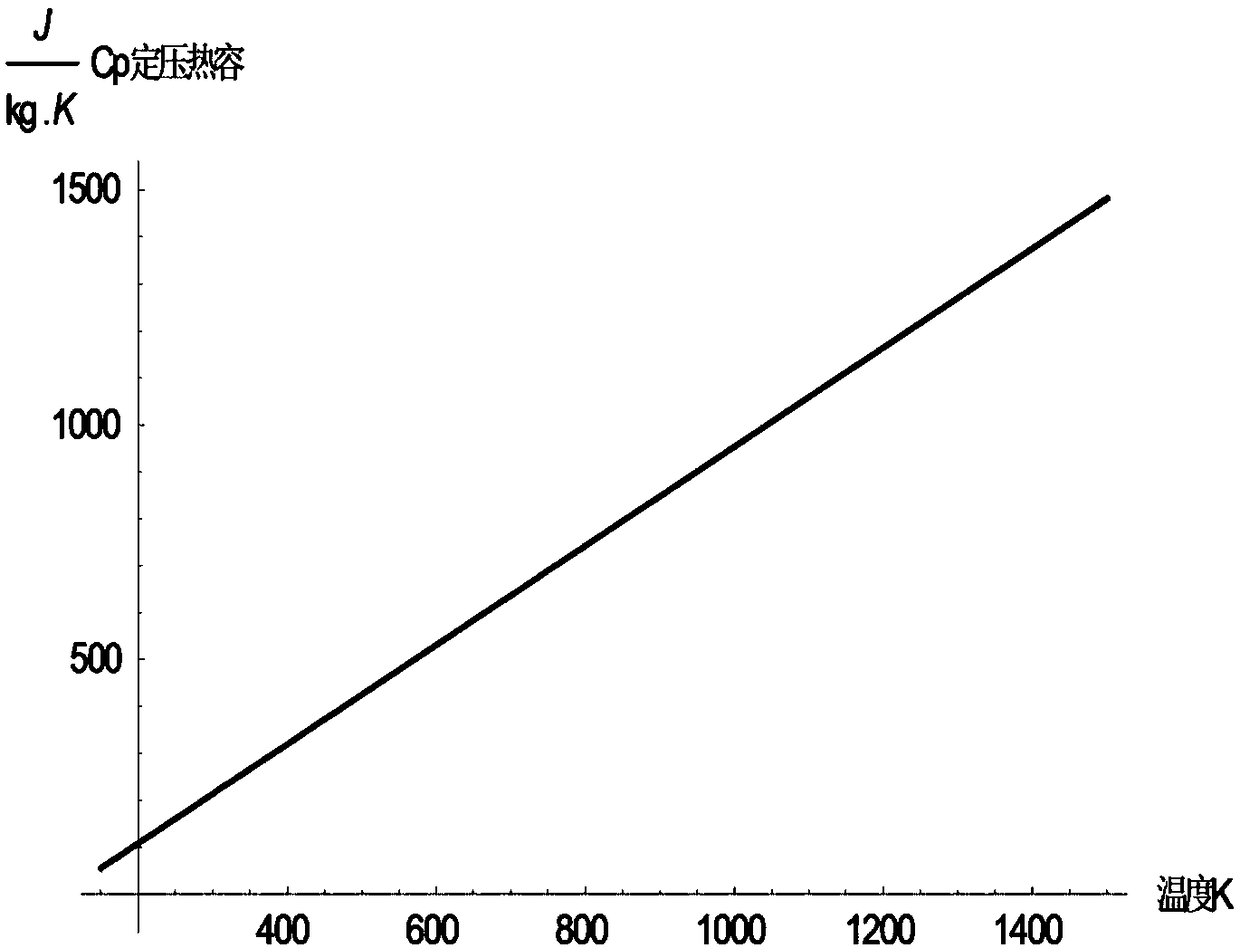

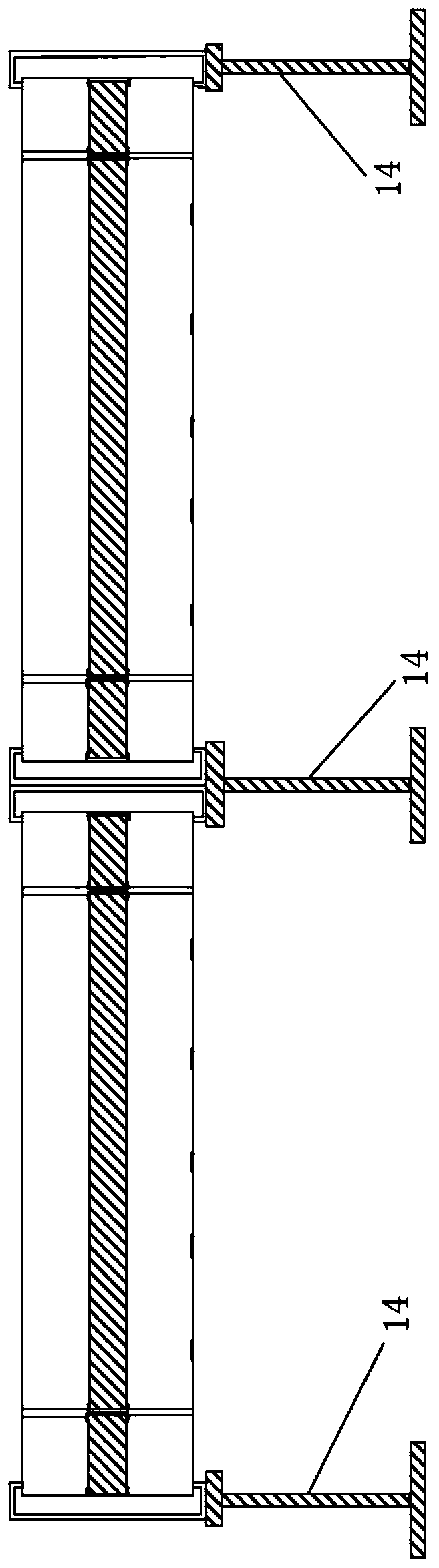

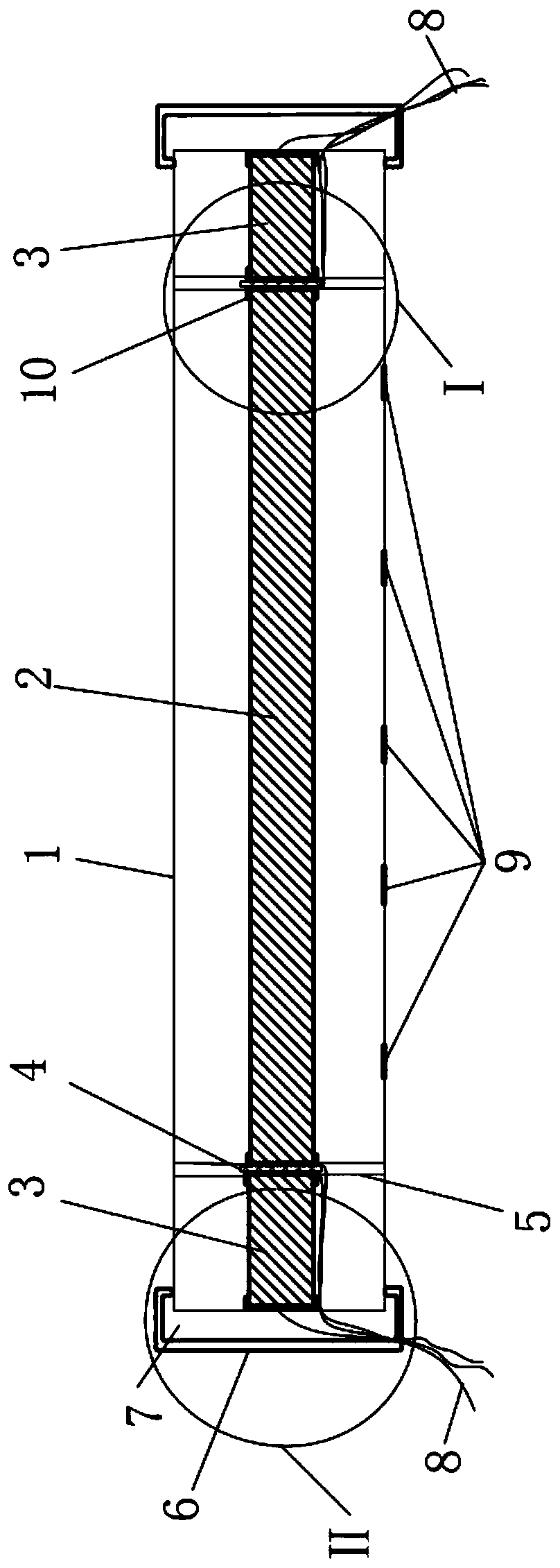

A test device for rapid heating of inert gas without pollution

ActiveCN109655276BFast heat storageHeating fastGas-turbine engine testingStorage heatersThermodynamicsEngineering

The invention discloses a no-pollution quick insert gas heating experiment device which belongs to the technical field of aerodynamic missile engine ground simulation experiment. The experiment comprises a graphite heat storage member, an electromagnetic induction coil and a pressure housing. The electromagnetic induction coil winds the graphite heat storage member. The electromagnetic induction coil is electrically connected with outer power distribution equipment. The graphite heat storage member is heated through electromagnetic induction. The graphite heat storage member and the outer electromagnetic induction coil are mounted in the pressure housing. Furthermore the air inlet channel and the air outlet channel of the graphite heat storage member penetrate the pressure housing. According to the experiment device, the graphite material is used as the heat storage member; the heat storage member is heated through the electromagnetic induction coil; after a preset temperature is reached, insert gas is introduced; the inert gas is heated by means of convection heat exchange between the surface of the heat storage member and the inert gas; and no-pollution heating to the inert gas can be quickly performed.

Owner:BEIJING POWER MACHINERY INST

A kind of solid-solid phase change material and preparation method thereof

ActiveCN110669475BHigh latent heat of phase changeLow costHeat-exchange elementsFiberInorganic salts

Owner:SHANDONG ANLENG NEW MATERIAL TECH CO LTD

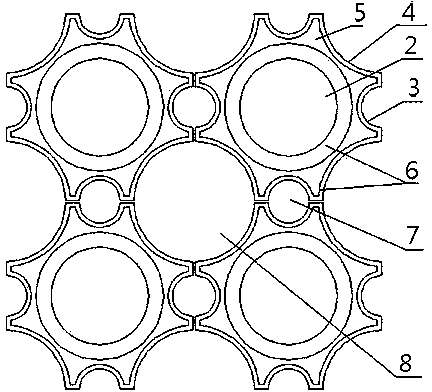

Flue gas purifier combination module

ActiveCN103816800ACorrosion resistantSimple structureDispersed particle separationFlue gasProcess engineering

The invention provides a flue gas purifier combination module. The flue gas purifier combination module comprises a cylinder filler body, the middle of the cylindrical filler body is provided with a central cylinder, four 1 / 2 arc surfaces are arranged on the outer wall of the central cylinder in every direction, a 1 / 4 arc surface is arranged between two adjacent 1 / 2 arc surfaces, each of the 1 / 2 arc surfaces and a 1 / 2 arc surface on an adjacent cylindrical filler body compose a small cylinder, each of the 1 / 4 arc surfaces and 1 / 4 arc surfaces on an adjacent four cylindrical filler bodies compose a large cylinder, bosses are arranged on the 1 / 2 arc surfaces and the 1 / 4 arc surfaces and at the edges of two ends of the central cylinder on the upper and lower end surfaces of the cylindrical filler body, a groove is formed between the bosses, and the diameter of the external circle of each of the bosses at two ends of the central cylinder is same to the diameter of the large cylinder composed of the four 1 / 4 arc surfaces.

Owner:启东恺峰农副食品有限公司

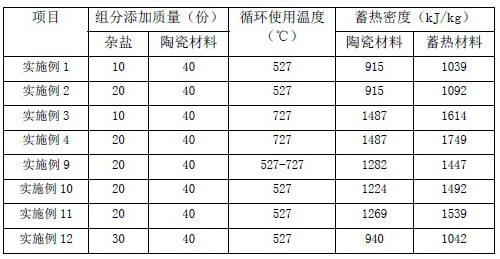

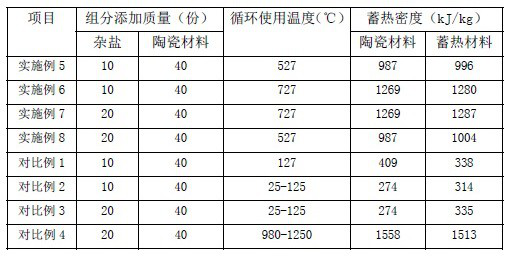

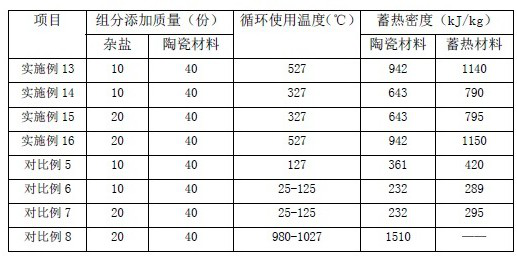

Impurity salt heat storage material and preparation method thereof

PendingCN114181673AFast heat storageFast heat releaseHeat-exchange elementsLatent heat storageHeat storage material

The invention provides a preparation method of a carnallite heat storage material, which comprises the following steps: (1) screening a ceramic material, and determining the addition amount of carnallite and the ceramic material; (2) calcining the carnallite to remove impurities; and (3) mixing the ceramic material screened in the step (1) with the carnallite calcined in the step (2), carrying out high-temperature pre-oxidation and hot press molding to fully sinter the sample, and cooling to room temperature to obtain the product. According to the carnallite heat storage material disclosed by the invention, carnallite is subjected to resource utilization, and the carnallite heat storage material has the advantages of a solid sensible heat storage material and a latent heat storage material and also overcomes the defects of the solid sensible heat storage material and the latent heat storage material, so that the carnallite heat storage material has the specific properties of rapid heat release, rapid heat storage and large heat storage density.

Owner:TIANJIN ENVIRONMENTAL PROTECTION TECHNICAL DEV CENT DESIGNING INST

Chinese herbal medicine solar energy phase change heat storage drying device and drying method

ActiveCN112082277BImprove thermal conductivityImprove heat storage capacitySolar heating energySolar heat storageMedicinal herbsThermodynamics

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

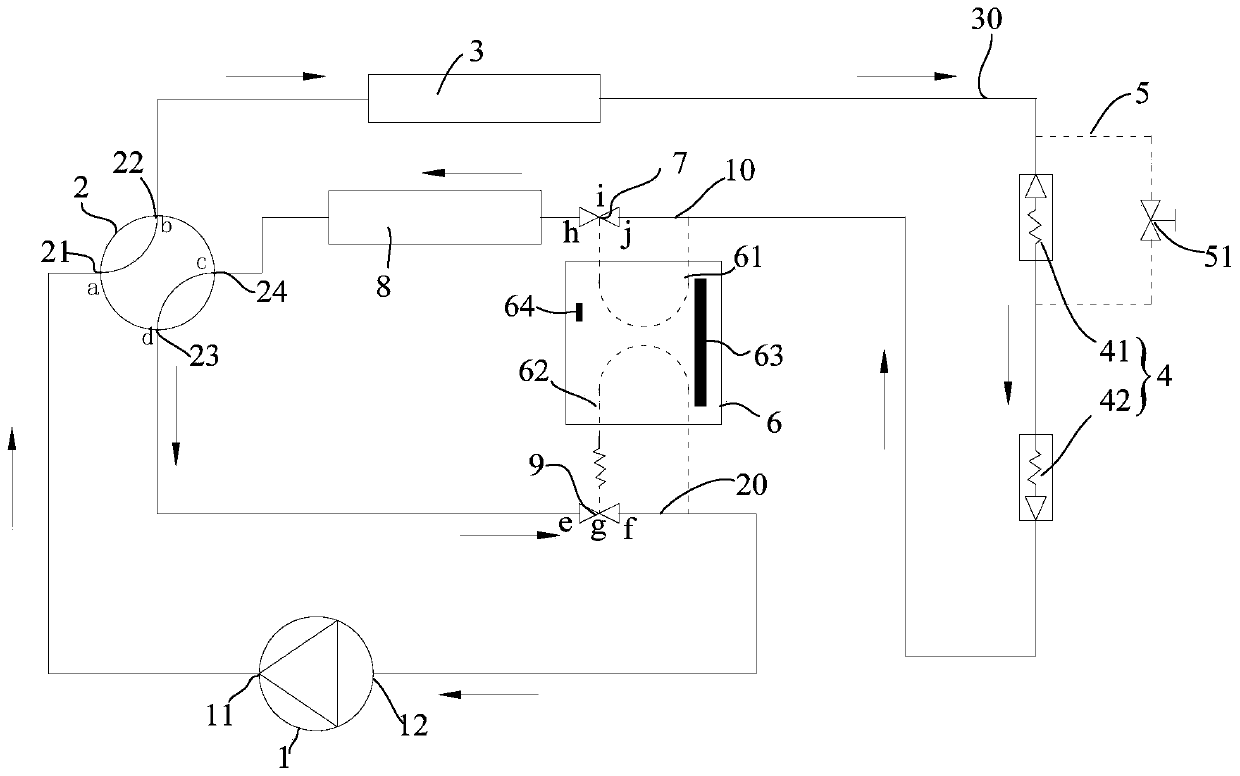

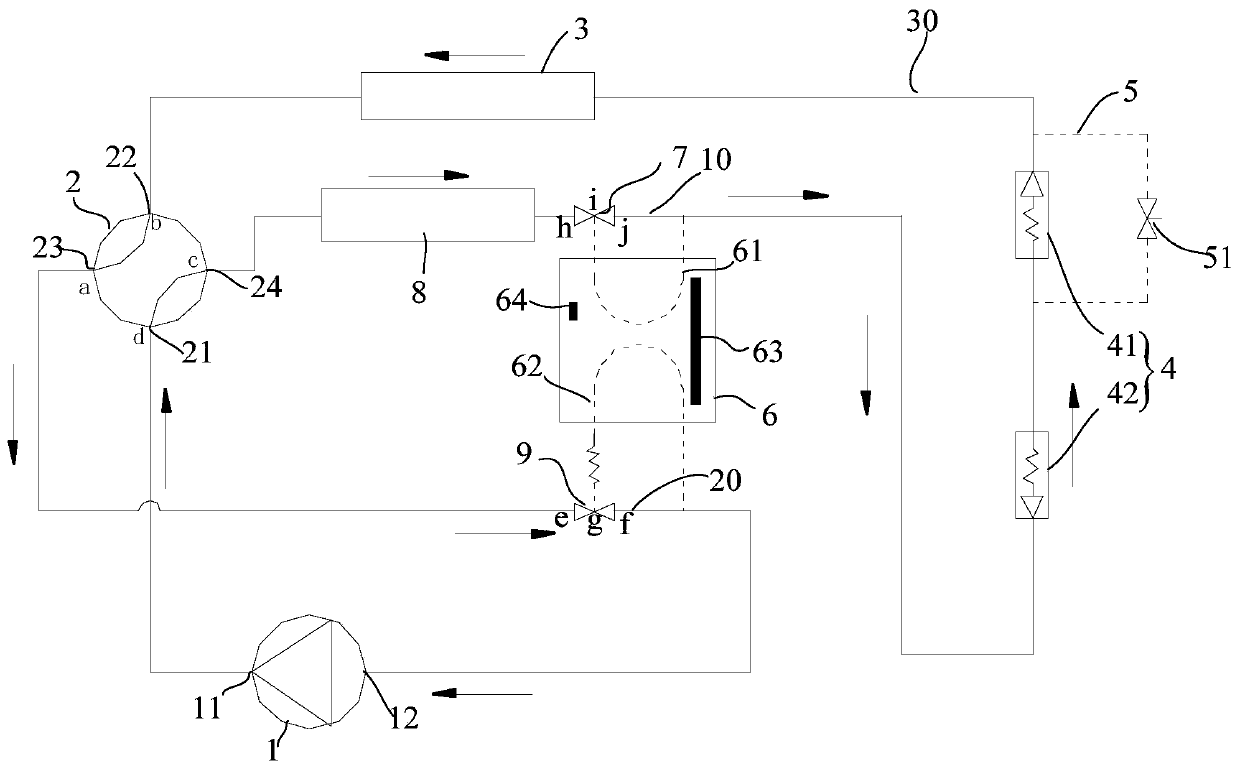

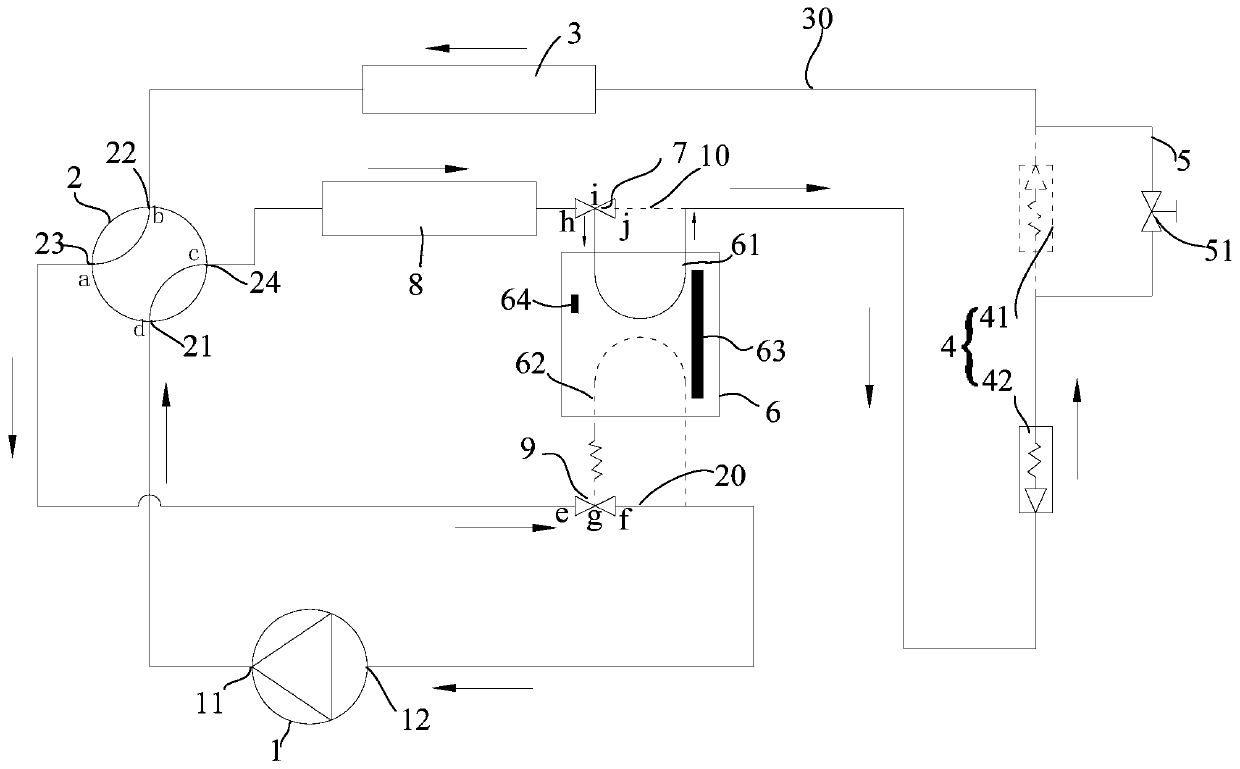

Air conditioner, control method thereof, control device and computer readable storage medium

ActiveCN110715486ALittle effect on heating capacityReduce heat lossMechanical apparatusCorrosion preventionProcess engineeringCold medium

The invention provides an air conditioner, a control method thereof, a control device and a computer readable storage medium. A heat accumulator comprises a first heat exchange tube and a second heatexchange tube, one end of the first heat exchange tube is connected with a third interface, the first heat exchange tube is connected with a first pipeline in parallel, and the second heat exchange tube is connected with a second pipeline in parallel. According to the air conditioner, in a defrosting mode, a first reversing element does not change the direction and can continuously supply heat tothe indoor, heating of the air conditioner is not influenced, and the use comfort of a user is not influenced. Due to the fact that the heat accumulator is arranged between a second end of an indoor heat exchanger and a second end of an outdoor heat exchanger, during heat storage, a refrigerant flows through the first heat exchange tube after flowing through the indoor heat exchanger, then the influence on the heating amount of the air conditioner during heat storage is small, the heat loss is reduced, and indoor temperature fluctuation is avoided.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

Heat storage type electric heater

ActiveCN110207244AIncreased efficiency in delivering heatImprove heating effectHeating fuelLighting and heating apparatusThermal expansionEngineering

The invention discloses a heat storage type electric heater, and belongs to the field of heating equipment. By installing a hollow cavity and a heat storage layer, the heat storage and the heating ofsurrounding gas are synchronously carried out, and the heating rate when the heater is just started is effectively improved; and meanwhile, in the using process, by arranging an inner heat conductionnet, the local overheating phenomenon caused by caking can be effectively avoided under the condition that the surface of an electric heating tube does not need rough treatment, and under the action of the hollow cavity, a lower-layer heat storage and an expansion gap, the volume increase of the heat storage layer caused by thermal expansion of the heat storage layer can be compensated at the sametime from the upper portion, the lower portion and the inner portion, the safety hazard caused by excessive expansion of the heat storage layer is effectively avoided, and the safety of the heater isobviously improved.

Owner:BEIJING GUDE ENERGY ENG

A waste heat energy recovery system coupled with a large phase-change heat storage tank

ActiveCN104501290BSuitable for waste heat recoveryFast heat storageHeat storage plantsSpace heating and ventilation detailsWater sourceCoupling

The invention provides a coupling type waste heat energy recovering system for a large phase-change heat storage cylinder. The system comprises a large phase-change heat storing cylinder assembly and a waste heat energy recovering assembly; the hot source inlet end of the large phase-change heat storing cylinder assembly is connected with a waste heat water source, and the heat supply outlet end of the large phase-change heat storing cylinder assembly is respectively connected with a direct heating device and an indirect heating device. The system is simple in structure; the heat of waste water is fully recovered and recycled; therefore, the function of fast storing heat and radiating heat can be achieved; the system is suitable for recycling of afterheat from the waste heat of liquid.

Owner:SOUTHEAST UNIV

A capillary phase-change thermal insulation piece, a building wall including the same, and a building

ActiveCN106351356BFast heat storageImprove heat transfer effectWallsHeat storage plantsThermal insulationEngineering

The invention discloses a capillary tube phase change insulation part, a building wall comprising the same and a building. The capillary tube phase change insulation part is used for thermal insulation of the building wall and is characterized by comprising a phase change material, a phase change packaging body for packaging a phase change substance and a heat exchange part arranged in the phase change material, the heat exchange part and the phase change material perform contact heat exchange to adjust the temperature of the building wall, and the heat exchange part comprises at least one first capillary tube arranged in the phase change material.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Low-water-level horizontal steam distributing pipe bottom-heating steam-jetting heat storage device

The invention discloses a low-water-level horizontal steam distributing pipe bottom-heating steam-jetting heat storage device, which comprises a heat storage device body, a heated steam distributing pipe and a steam connecting pipeline, wherein the heated steam distributing pipe is horizontally arranged on the lower part of a water space inside a heat storage device shell along the length direction of the heat storage device, two ends of the heated steam distributing pipe are closed, the inner sides at quarter length of the heated steam distributing pipe are respectively provided with a steam inlet, and an upper semicircular pipe wall of the heated steam distributing pipe is provided with a plurality of steam jetting holes; and the steam connecting pipe comprises a first connecting pipe, two second connecting pipes and a third connecting pipe, wherein one end of the first connecting pipe is communicated with a steam inlet pipe, the other end of the first connecting pipe is communicated with the middle part of the third connecting pipe, two steam outlets facing downwards on two ends of the third connecting pipe are respectively communicated with the middle parts of the two second connecting pipes, and two ends of each second connecting pipe are respectively connected with the steam inlets at the inner side of the heated steam distributing pipe. Due to the adoption of the steam heat storage device, the economic benefit and the social benefit of energy conservation, emission reduction and carbon reduction of the heat storage device can be improved.

Owner:BEIJING MINGCHENG TECH DEV

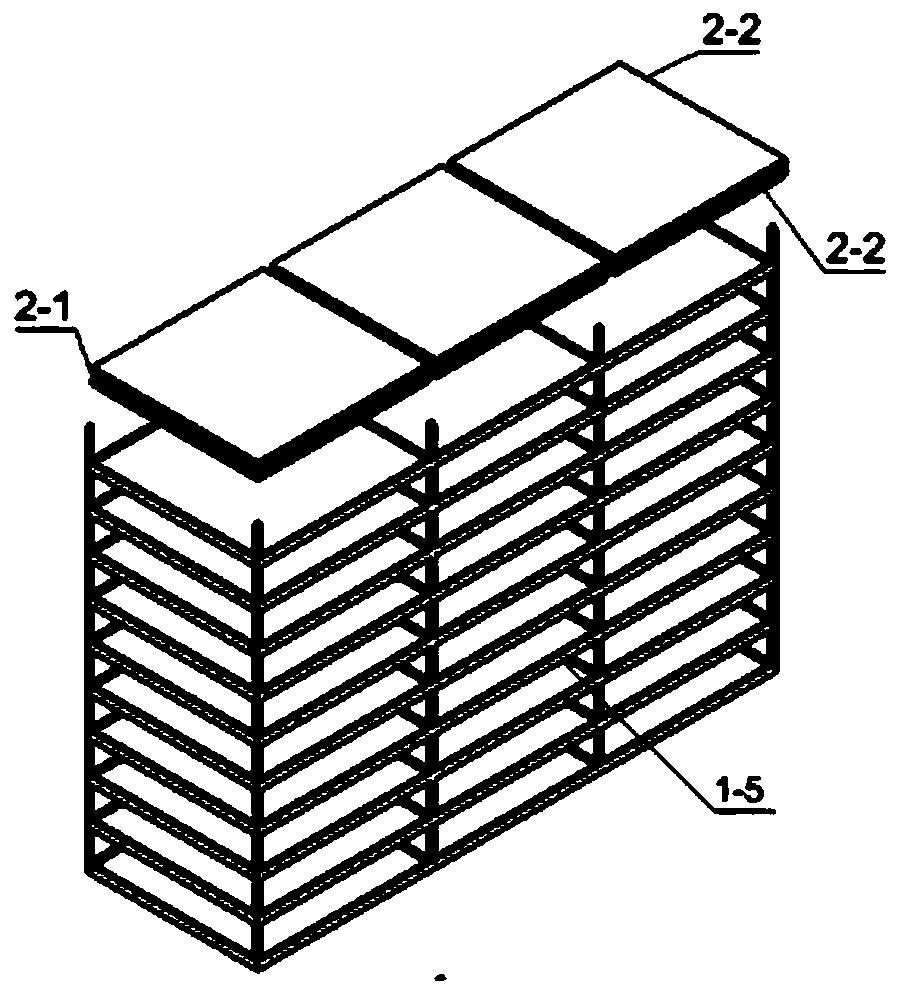

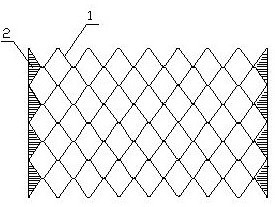

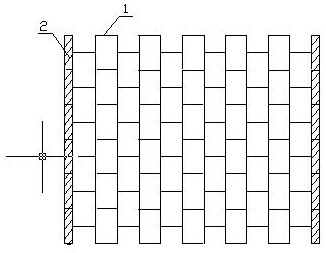

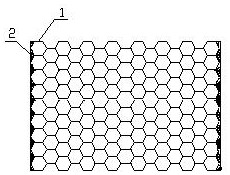

A large-scale integral honeycomb ceramic regenerator and its preparation method

The invention discloses a large-scale integrated honeycomb ceramic heat accumulator and a preparation method thereof. The preparation method comprises the following steps: rolling a preform body intocorrugated blank slices through a rolling machin; stacking the corrugated blank slices into an integrated honeycomb type corrugated green body by using an adhesive according to a peak-to-peak, valley-to-vallye and rib-to-rib way; drying, flatly cutting two ends of the corrugated green body which stretches along ripples, forming corrugated grooves vertical to a stretching direction, filling and flatly repairing the corrugated grooves by using the preform body, and sealing the two ends of the corrugated green body which stretches along the ripples; then setting decompression grooves in the end surface of the corrugated green body; putting the corrugated green body in a kiln, firstly rising the temperature to 600 DEG C at a low speed, keeping warm for 1 to 1.5 hours, then quickly rising the temperature to 1200 to 1600 DEG C, keeping warm for 2 to 4 hours, and discharging after furnace cooling, thus obtaining the integrated honeycomb ceramic heat accumulator. According to the large-scale integrated honeycomb ceramic heat accumulator and the preparation method thereof, disclosed by the invention, the original advantages of shape regularity, attractiveness and practicability, good thermal stability, small back pressure, large specific surface area, fast heat exchange and good slag resistance are kept, organic volatile matters cannot be generated during firing, the environment cannotbe polluted, and the production cost can also be reduced.

Owner:JIANGXI BOCENT TEC CO LTD

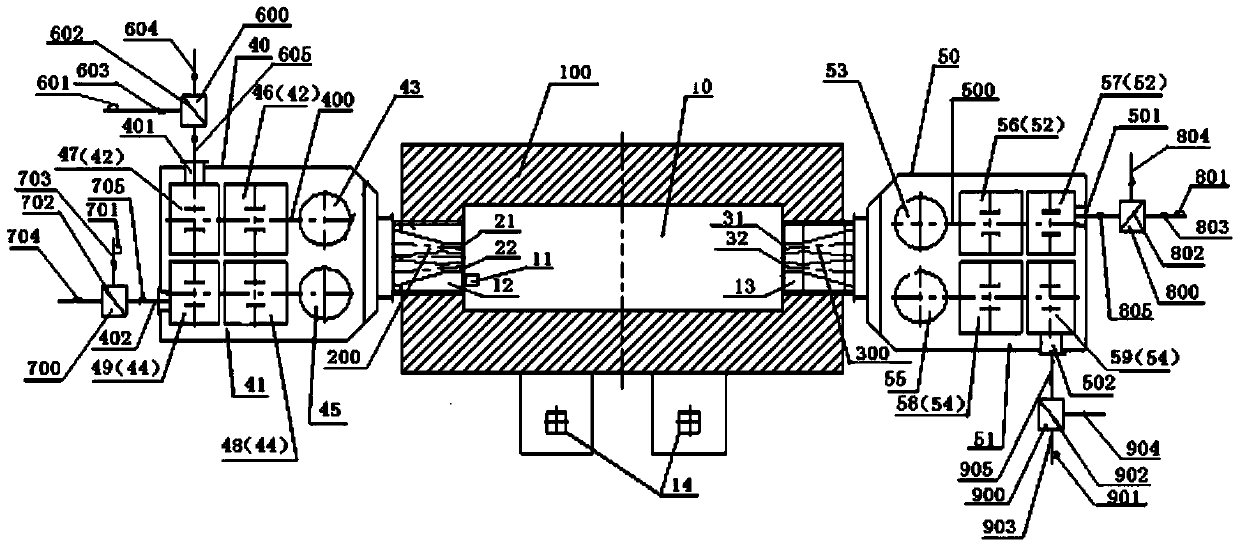

Reduction smelting regenerative combustion system and method for smelting using the system

ActiveCN105402732BAvoid destructionAvoid local oxidationIncreasing energy efficiencyIndirect carbon-dioxide mitigationCombustion systemProcess engineering

The invention discloses a reductive smelting heat-accumulation type combustion system and a smelting method using the same. The reductive smelting heat-accumulation type combustion system comprises a furnace body, a first nozzle, a second nozzle, a first heat accumulation device, a second heat accumulation device, a first air three-way valve, a first coal gas three-way valve, a second air three-way valve and a second coal gas three-way valve. The first heat accumulation device comprises a first shell. A first heat storage space is defined in the first shell. A first air heat accumulator, a first settling chamber, a first coal gas heat accumulator and a second settling chamber are arranged in the first heat storage space. The second heat accumulation device comprises a second shell. A second heat storage space is defined in the second shell. A second heat accumulator, a third settling chamber, a second coal gas heat accumulator and a fourth settling chamber are arranged in the second heat storage space. By the adoption of the reductive smelting heat-accumulation type combustion system, waste heat in smoke can be efficiently recovered, and thus the energy utilization rate is remarkably increased.

Owner:SHENWU TECH GRP CO LTD

A high-efficiency and high-precision natural convection heat release coefficient measurement experimental device

ActiveCN107064209BGuaranteed calorific valueReduce axial heat lossMaterial heat developmentThin film thermocouplesEngineering

The invention provides a high-efficiency and high-precision measurement experimental device for a natural convection heat transfer coefficient. The device comprises a unit-pipe pipe wall, a primary heating rod, an auxiliary heating rod, an insulating sheet, a heat-insulation jacket, heat-isolation end covers, a film thermocouple, terminal sleeves, an A / D (Analog / Digital) converter, a computer, a control box and a bracket. The insulating sheet is inserted between the primary and auxiliary heating rods of the device to form close connection; pipe cavities at an effective experimental section and an auxiliary experimental section which are corresponding to the primary and auxiliary heating rods respectively are spaced by using the annular heat-insulation jacket; the temperatures of the adjacent terminal sleeves of the primary and auxiliary heating rods are controlled to be the same through regulating the current and the voltage of the auxiliary heating rod, so as to reduce the axial heat loss of the primary heating rod; the internal surface silvered heat-isolation end covers are sleeved at each unit-pipe port; high-temperature-resistant heat-isolation foam mats are filled in gaps among the heat-isolation end covers and unit pipes, so as to reduce the heat loss due to radiation at an auxiliary-section port; the external surfaces of the unit pipes are slivered, and the internal surfaces of the unit pipes are plated with high-radiance materials, so as to shorten an experimental time. The measurement problem of the natural convection heat transfer coefficient is solved highly efficiently and highly precisely.

Owner:XIANGTAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com