A waste heat energy recovery system coupled with a large phase-change heat storage tank

A technology of phase change heat storage and heat energy recovery, which is applied in heating systems, heat storage equipment, household heating, etc., can solve the problems of long charging and discharging time, small heat exchange area and heat storage, and single function, and achieve Expand the heat exchange area, alleviate the difference between peak and valley, and improve the effect of economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

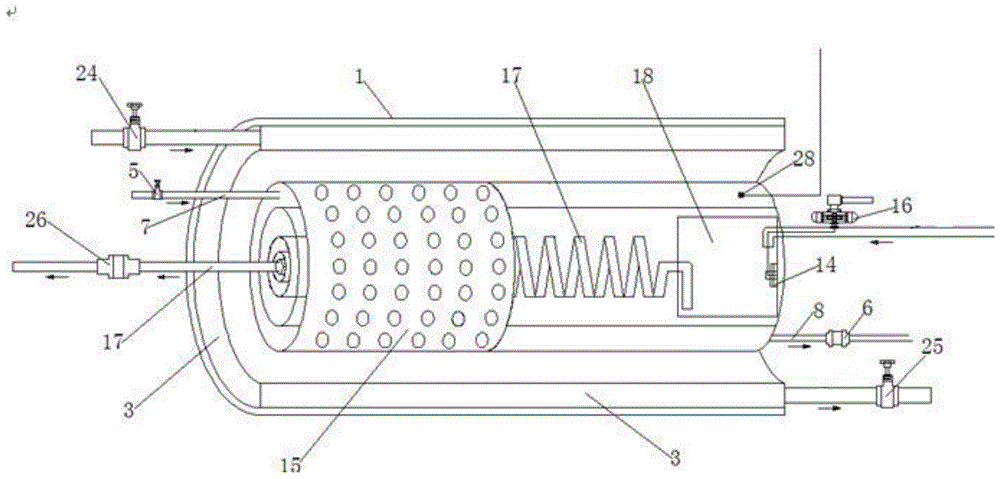

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

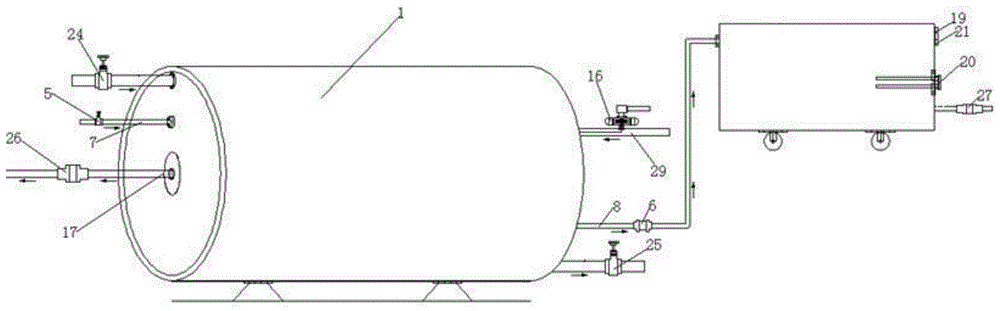

[0021] as attached figure 1 , 2 As shown in and 3, a waste heat energy recovery system coupled with a large phase-change thermal storage tank includes a large phase-change thermal storage tank assembly and a waste heat energy recovery assembly; the heat source inlet port of the large phase-change thermal storage tank assembly is connected to a waste heat source, The heat supply outlets of the phase change heat storage large tank assembly are respectively connected to direct heating and indirect heating equipment. The direct heating equipment is a heating room fan, and the indirect heating equipment is a waste heat recovery component.

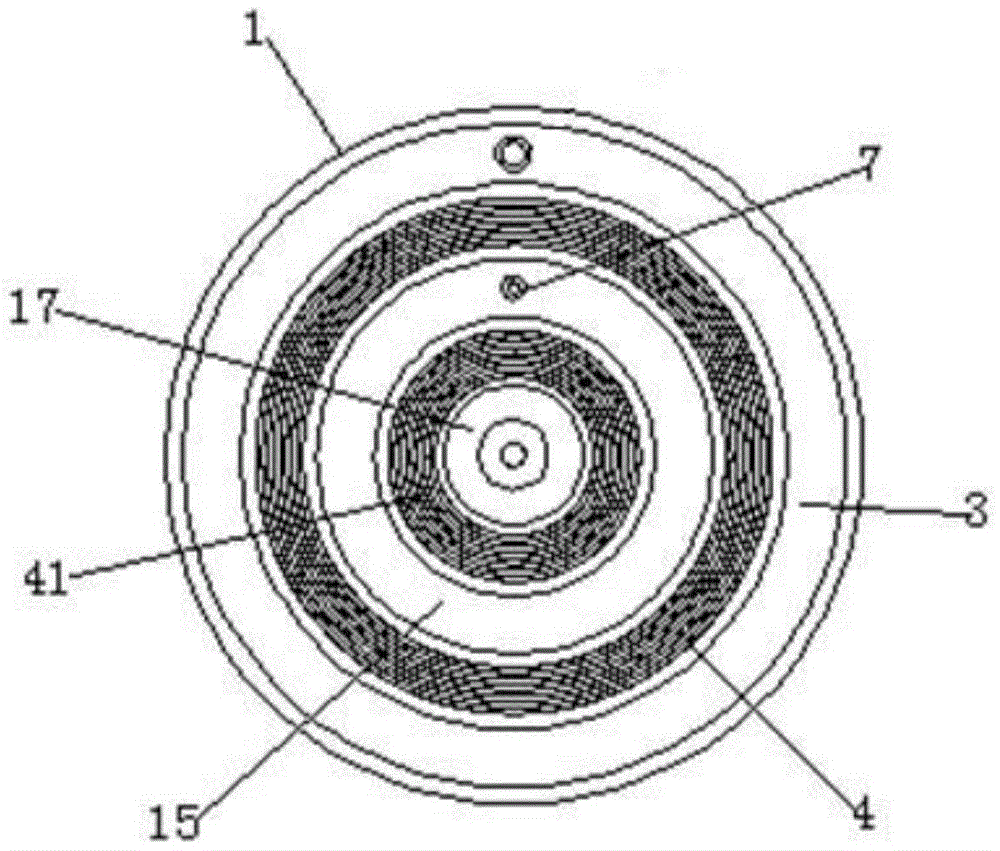

[0022] The large phase-change thermal storage tank assembly includes a large phase-change thermal storage tank 1, in which a drum-type waste water tank 3 and an outer phase-change medium paraffin layer are sequentially arranged in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com