Continuous-casting two-cooling-section waste heat power generation method and equipment based on organic working medium Rankine cycle

A Rankine cycle, waste heat power generation technology, applied in mechanical equipment, machines/engines, steam engine installations, etc., can solve the problems of poor heat exchange effect and low utilization rate of waste heat, and achieve easy popularization and application, excellent safety, and satisfaction. The effect of exothermic heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

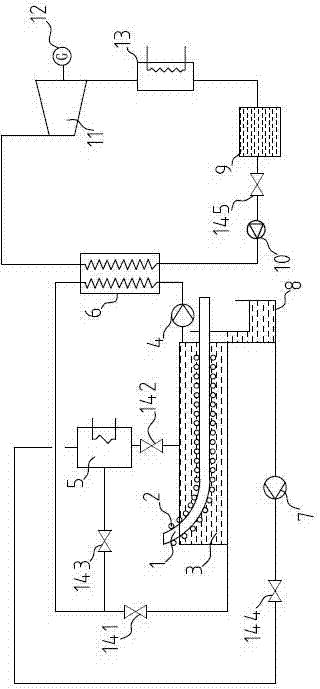

[0016] Depend on figure 1 The schematic diagram of the waste heat power generation method and equipment embodiment in the secondary cooling section of continuous casting based on the organic working medium Rankine cycle shows that it includes a waste heat recovery system, a heat exchanger 6 and an organic working medium connected to the heat exchanger 6 Rankine cycle power generation system. Wherein, the waste heat recovery system includes a medium-temperature salt bath 3 with a roller shaft 2 inside and a medium-temperature molten salt furnace 5 connected to the medium-temperature salt bath 3 , and the medium-temperature salt bath 3 is connected to a heat exchanger 6 . In addition, the medium-temperature salt bath 3 is connected with a liquid collection pool 8 , and the liquid collection pool 8 is connected with the medium-temperature molten salt furnace 5 . The heat exchanger 6 is also connected to the power generation system. The organic working medium Rankine cycle power ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com