Disturbance mixing rapid heat storage module

A heat storage and module technology, applied in heat storage equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as uneven heat transfer, slow heat storage and release rates, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

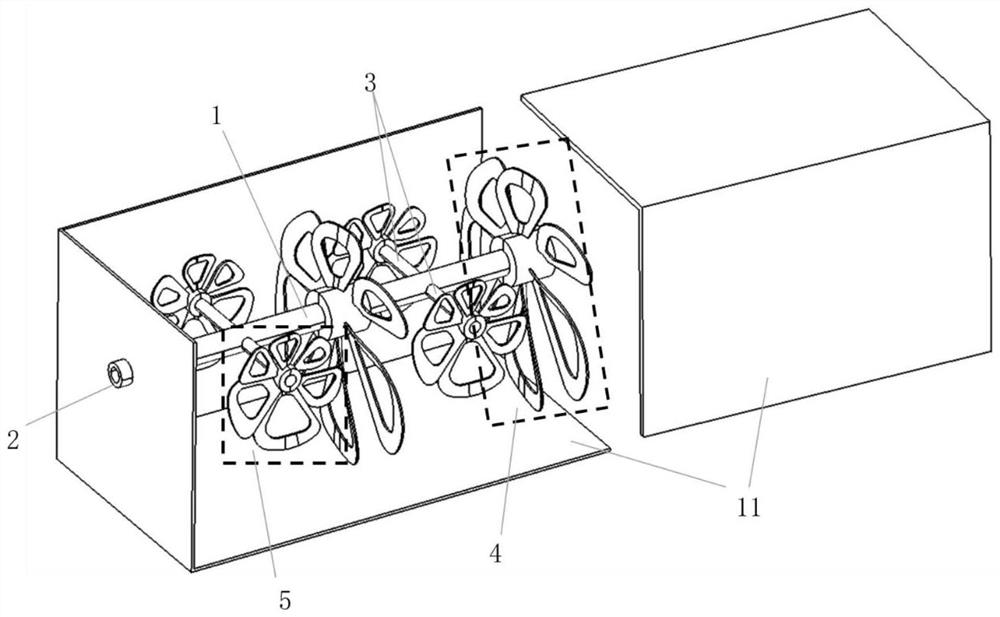

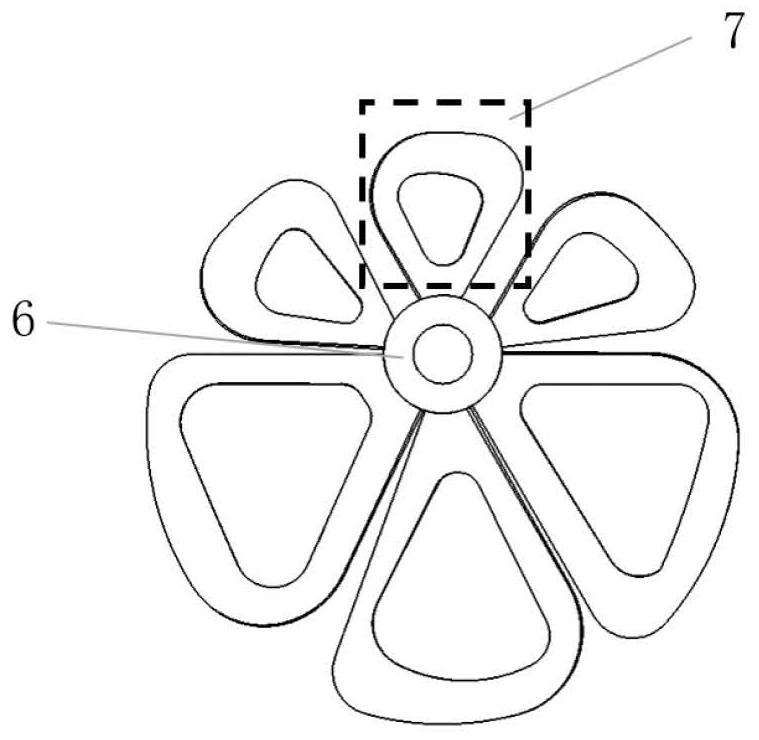

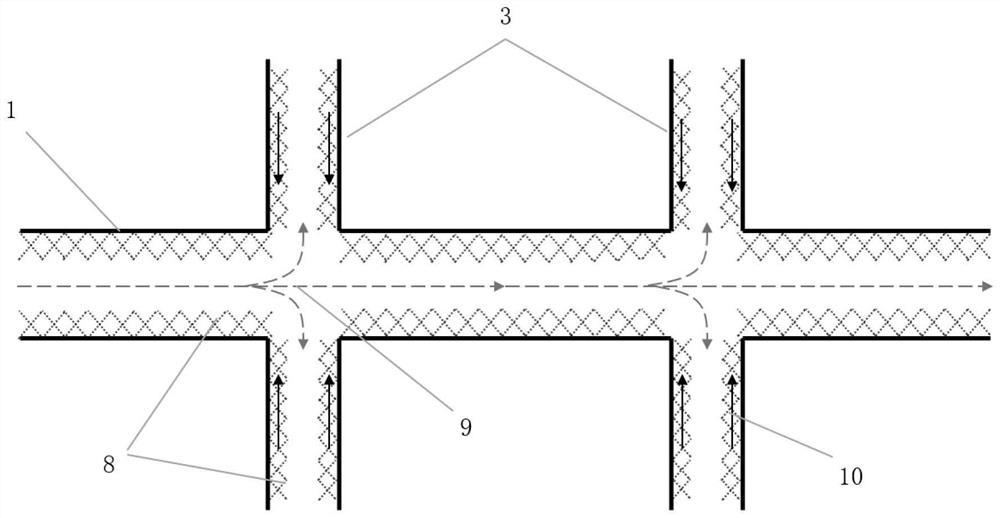

[0027] Figure 1-Figure 4 It is a structural schematic diagram of each part of the turbulent mixing fast heat storage module provided by the present invention.

[0028] The present invention will be specifically described below in conjunction with the accompanying drawings. A disturbance mixing rapid heat storage module, its overall structure consists of a central columnar steam chamber 1, a skeleton rotatable support 2, a branch steam chamber 3, axial fan-shaped fins 4, and radial fan-shaped fins 5 And phase change container 11 forms. The outer walls of the columnar steam chamber 1 and the branch steam chamber 3 are made of materials with high thermal conductivity (such as copper and aluminum), and the central columnar steam chamber 1 has a rotatable degree of freedom in connection with the phase change container 11 through the rotatable support 2 of the skeleton. , under the action of external impact or disturbance, because the symmetrically distributed branch steam chambe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com