Gland type safety pressure cooker

A lid-pressing and pressure cooker technology is applied in the field of kitchen utensils, which can solve the problems of the left and right displacement of the pressure-holding beam, the uneven heat conduction of the bottom of the pot, and the inability to adapt to stoves, etc., and achieves good versatility, good adhesion performance, and tightness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

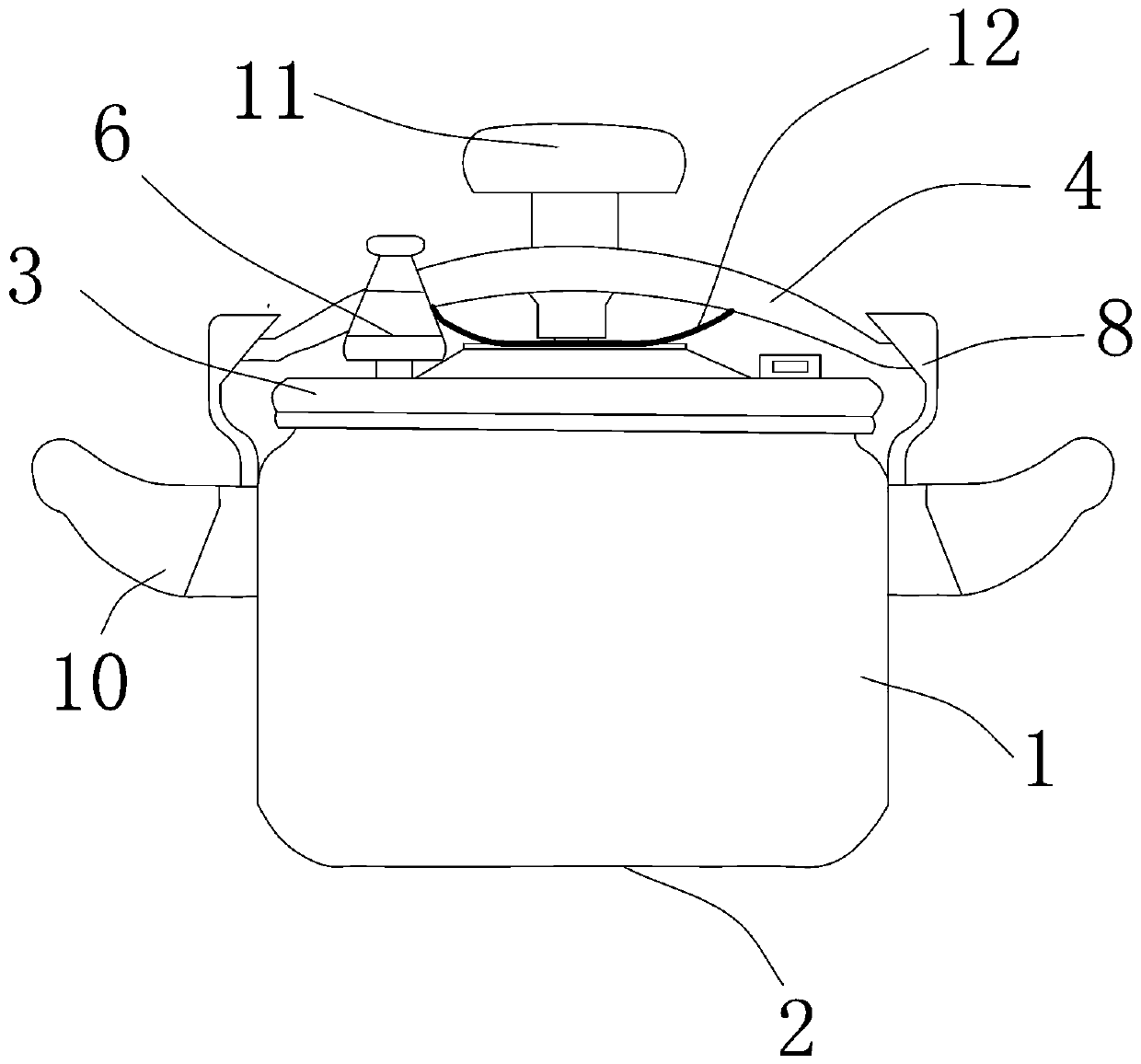

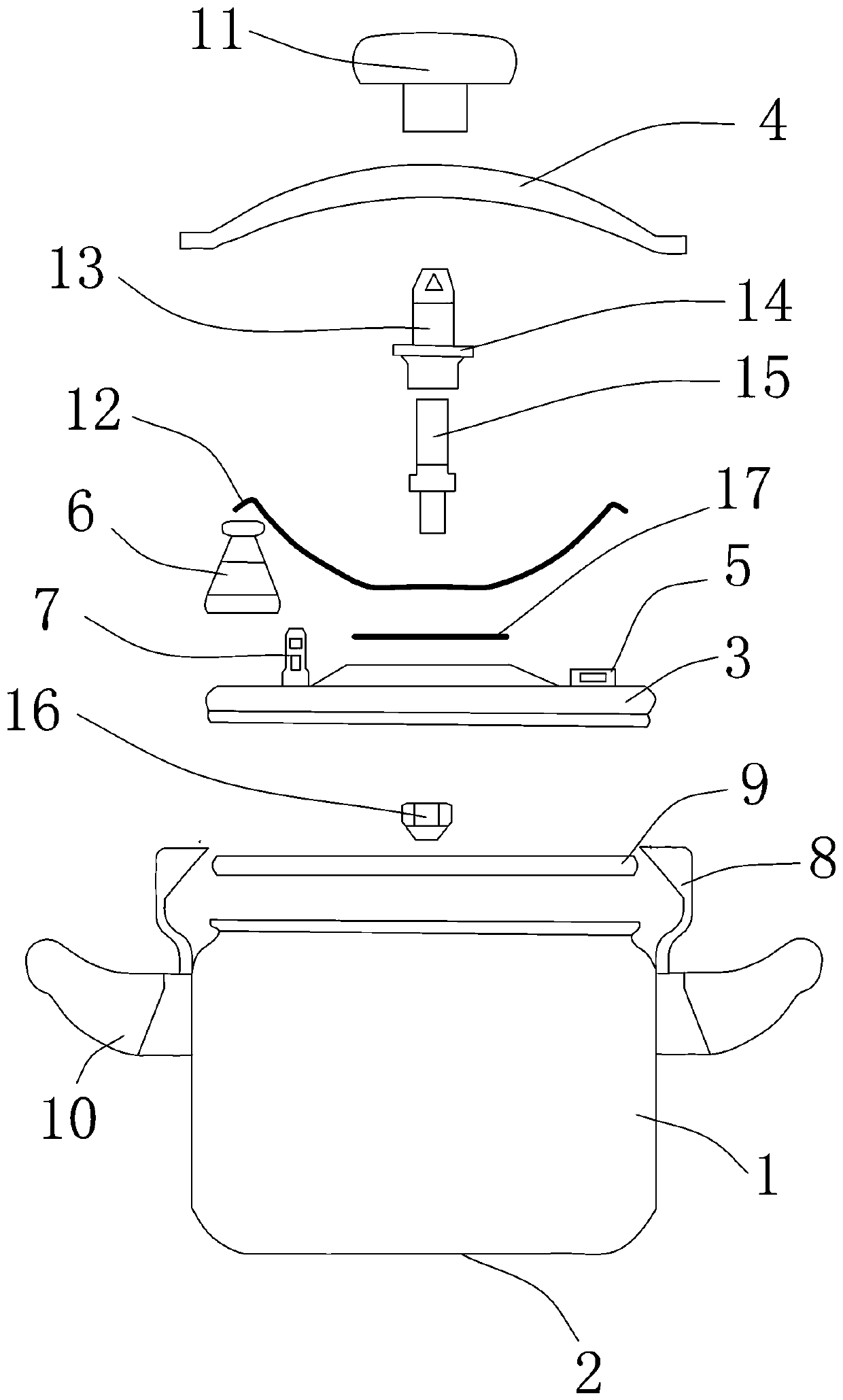

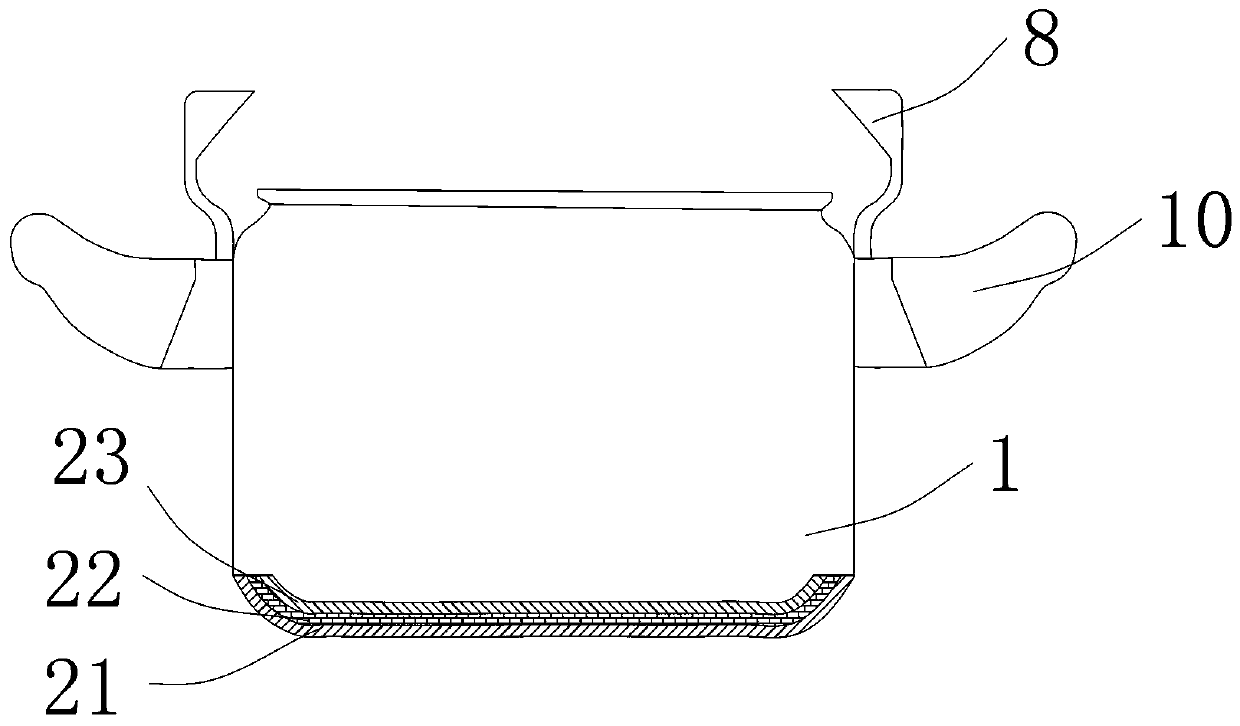

[0015] see Figure 1-3 As shown, the present invention relates to a gland type safety pressure cooker, comprising a pot body 1, a pot bottom 2 and a pot cover 3, the pot body 1 and the pot bottom 2 are an integrated structure, and the pot bottom 2 is a three-layer composite structure, including a guide Magnetic stainless steel outer layer 21, aluminum interlayer 22 and food-grade 304 stainless steel inner layer 23, three-layer composite pot bottom, made of 1600 tons of friction pressure, durable, and the lid 3 is equipped with a pressure beam 4, opening and closing Locking device, safety valve 5, pressure limiting valve 6 and exhaust pipe 7, the holding beam 4 is fixed on the pot cover 2 through the opening and closing locking device, and the two sides of the pot body 1 are respectively provided with one for buckling the holding beam 4 The pot ears 8 at both ends, the pot ears include a horizontal section, a vertical section, a fixed section extending from the bottom of the ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com