Flue gas purifier combination module

A purifier and flue gas technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of large construction investment, large floor space, and high operating costs, and achieve high denitrification rate and large heat storage , fast denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

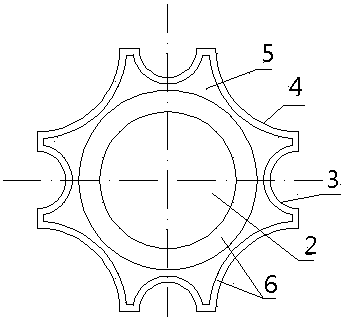

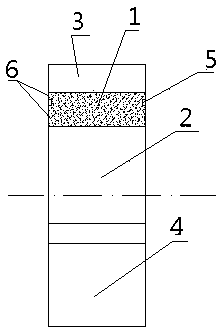

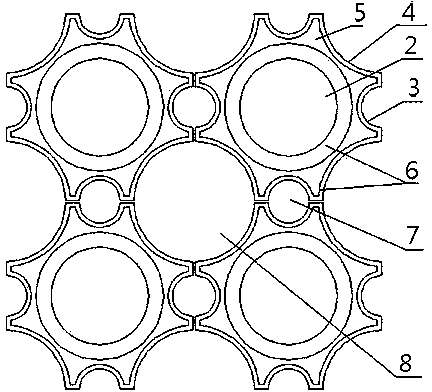

[0015] As shown in the attached figure, a honeycomb-shaped purifier is built by staggering the combined modules layer by layer. After the flue gas enters the purifier, it is mixed with the atomized reducing agent to reduce the nitrogen oxides in the flue gas and eliminate nitrogen oxides. The concentration of pollutants reaches pollution-free discharge, and the staggered arrangement of masonry enables the modules to bite each other. The adjacent modules and the layers are cemented and sealed by refractory cement, which greatly improves the sealing and firmness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com