Mine waste heat cascade utilization integrated system

A mine and waste heat technology, applied in mine/tunnel ventilation, mining equipment, mining equipment, etc., can solve the problems of excessive heat utilization in shallow layers, large water demand for heat dissipation, high noise, etc., to avoid heat damage problems, The effect of meeting building energy consumption and reducing mine temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

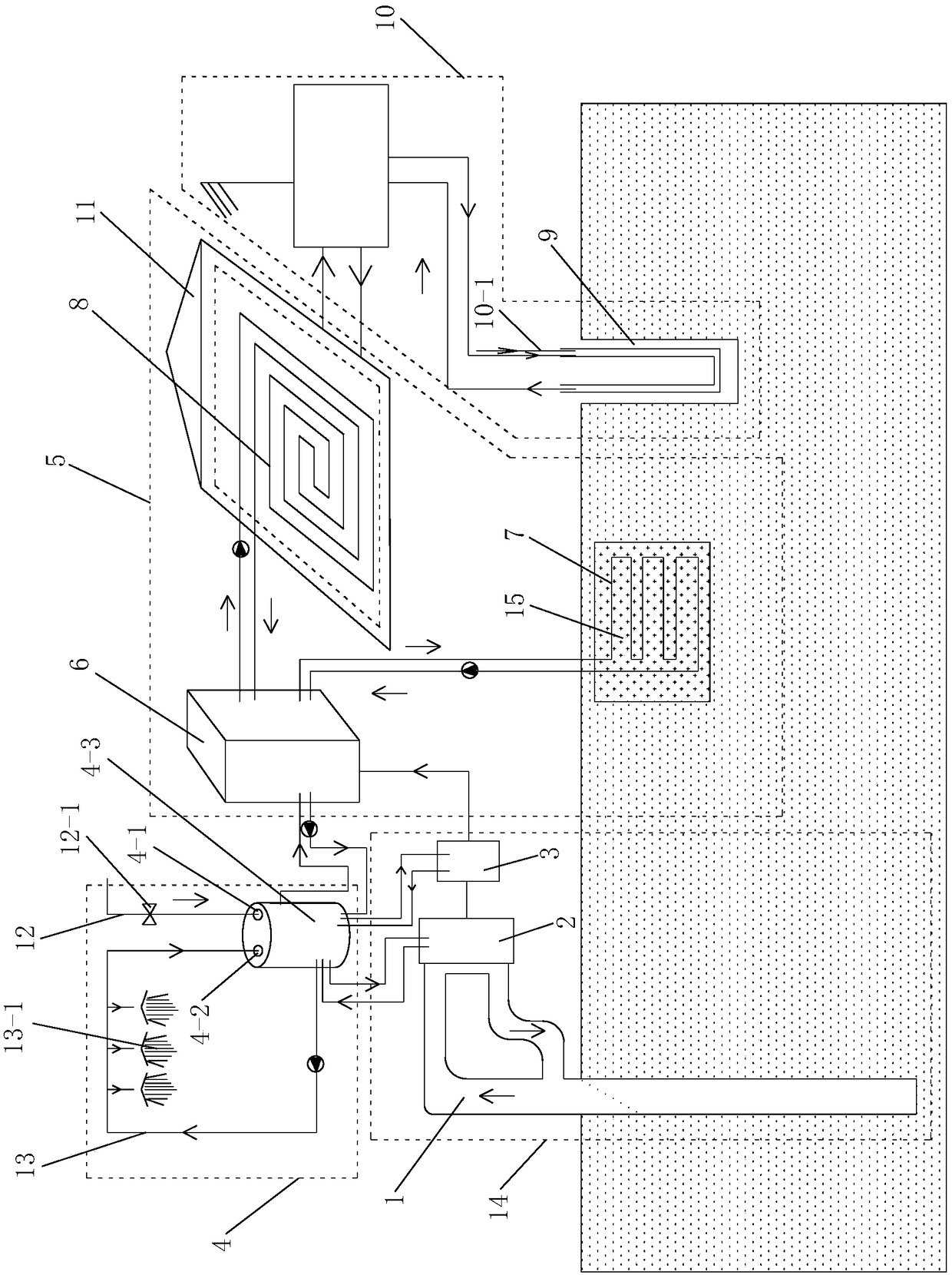

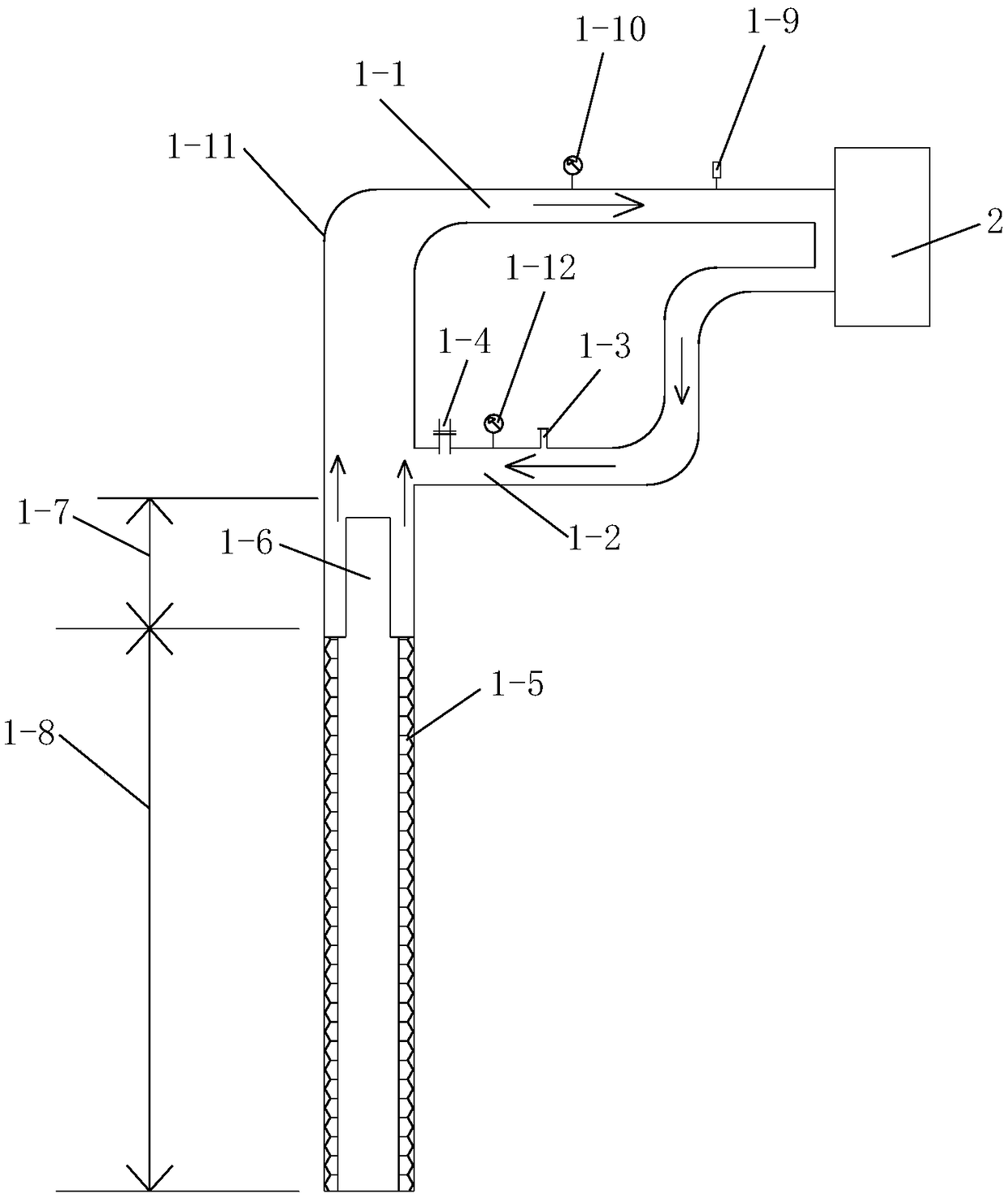

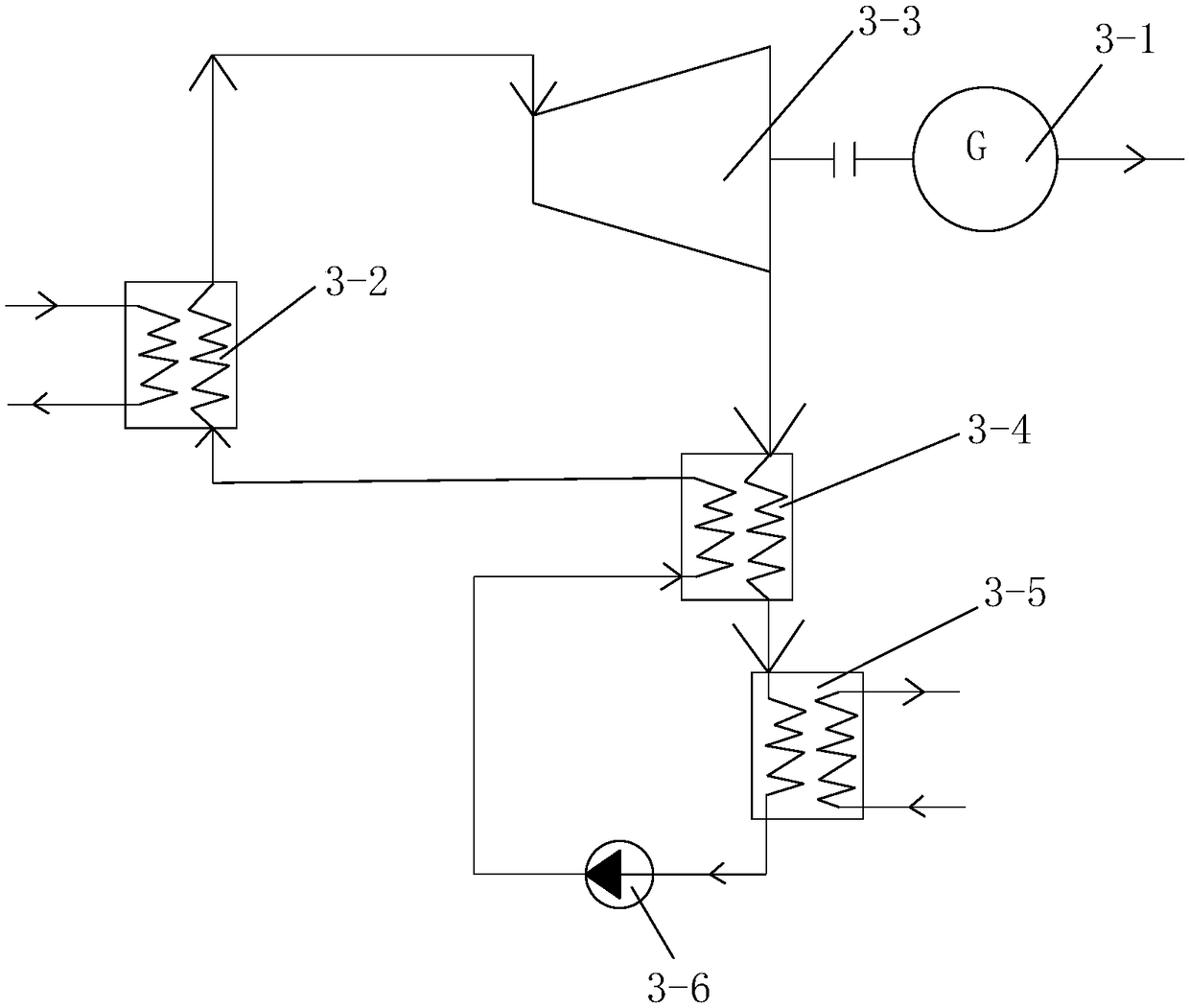

[0044] Such as figure 1 As shown, the present invention includes a deep mine waste heat utilization system for extracting mine deep waste heat for power generation to supply building HVAC equipment and domestic hot water, and a mine shallow waste heat utilization system for extracting mine shallow waste heat for indoor heating and cooling. The mine deep waste heat utilization system includes a power supply system 14 and a hot water supply system 4. The power supply system 14 includes a deep waste heat heat pipe collection system 1, a first heat exchanger 2 and a power generation system 3 connected in sequence. The first heat exchange Both the device 2 and the power generation system 3 are connected to the hot water supply system 4; the mine shallow waste heat utilization system includes a water heating and cooling system 5 and a fresh air treatment system 10, and the water heating and cooling system 5 includes underground pipes 7, The heat pump unit 6 and the floor radiant tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com