A kind of oil recovery method utilizing alkaline electrolysis water flooding

A technology of electrolysis of water and alkalinity, which is applied in chemical instruments and methods, production fluids, earth drilling and production, etc., can solve problems affecting the production efficiency of ASP flooding, increased operating costs, and difficulty in handling the produced fluid, and achieve emulsification Good effect, low cost and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Oilfield A was developed by water flooding, because the water content of the production wells produced by water flooding for many years is 99%, the salinity of the formation water is 5160 mg / L, and the viscosity of the crude oil is 110 mPa.s.

[0025] 1) Compatibility experiment: The pH of the alkaline electrolyzed water is 13.3, and the alkaline electrolyzed water is mixed with water injection to obtain the oil displacement liquid. Compared with the NaOH solution of the same pH value, the compatibility experiment with the formation water is as follows:

[0026] Table 1 Compatibility of flooding fluids with different concentrations and formation water

[0027] serial number

Alkaline electrolyzed water concentration

pH

Compatibility phenomenon

NaOH solution

Compatibility phenomenon

1

20%

10

No precipitation

20%

Precipitation is produced

2

40%

12.5

No precipitation

40%

Precipitation is produced

...

Embodiment 2

[0035] Oilfield B was developed by water injection. The water content of the production well was 65%, the salinity of the formation water was 10160 mg / L, and the viscosity of the crude oil was 20 mPa.s.

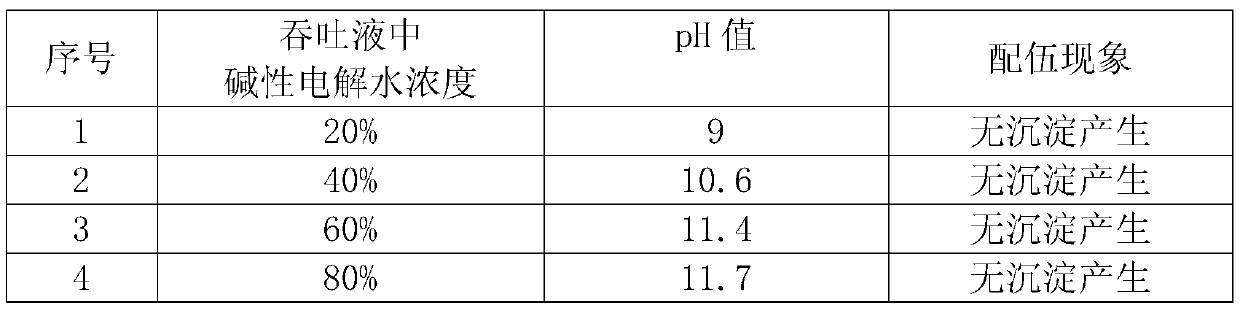

[0036] 1) Compatibility experiment: The pH of alkaline electrolyzed water is 13.9, and the alkaline electrolyzed water is mixed with water injection to obtain oil displacement. The compatibility experiment with formation water is as follows:

[0037] Table 3 Compatibility phenomenon of alkaline electrolyzed water with different concentrations and formation water

[0038] serial number

Alkaline electrolyzed water concentration

pH

Compatibility phenomenon

1

20%

12.8

No precipitation

2

40%

13

No precipitation

3

60%

13.2

No precipitation

4

80%

13.6

No precipitation

[0039] It can be seen that the range of the added concentration of alkaline electrolyzed water meets the water flooding condit...

Embodiment 3

[0046] Oilfield C, without water injection, the water content of the production well fluid is 98%, the salinity of the formation water is 10000mg / L, and the viscosity of the crude oil is 40mPa.s.

[0047] 1) Compatibility experiment: The pH of alkaline electrolyzed water is 11.8, and the alkaline electrolyzed water is mixed with water injection to obtain huff and puff. The compatibility experiment with formation water is as follows:

[0048] Table 5 Compatibility experiment of alkaline electrolyzed water with different concentrations and formation water

[0049]

[0050] It can be seen that the range of the added concentration of alkaline electrolyzed water meets the water flooding conditions of no precipitation and pH ≥ 8, and the specific concentration is screened by the effect of the core physical simulation oil displacement experiment.

[0051] 2) Huff and puff concentration experiment: The single-well huff and puff model experiment was carried out using alkaline electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com