Diagonal splicing connection structure of all aluminum furniture frame

A connection structure and frame technology, which is applied in the direction of furniture connections, furniture connectors, connection components, etc., can solve the problems of unfavorable furniture production costs and high cost of corner codes, and achieve the goal of eliminating cutting processes, reducing manufacturing costs, and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the embodiments of the drawings.

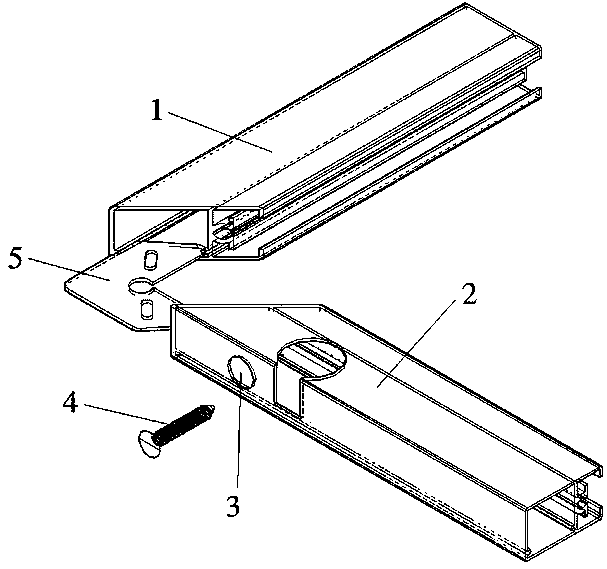

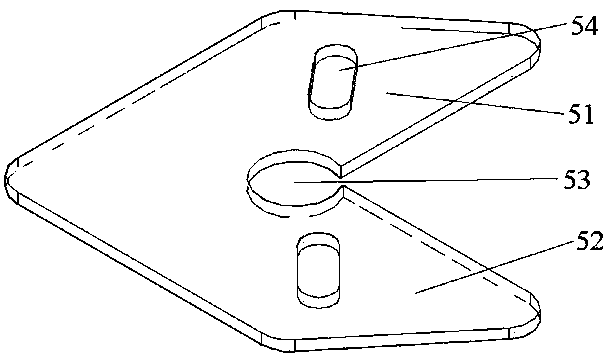

[0038] Such as Figure 1~Figure 3 As shown, an all-aluminum furniture frame diagonal connection structure in this embodiment includes a first frame 1 and a second frame 2. The first frame 1 and the second frame 2 are arranged perpendicular to each other, and the first frame The first frame 1 and the second frame 2 are connected by connecting screws 4;

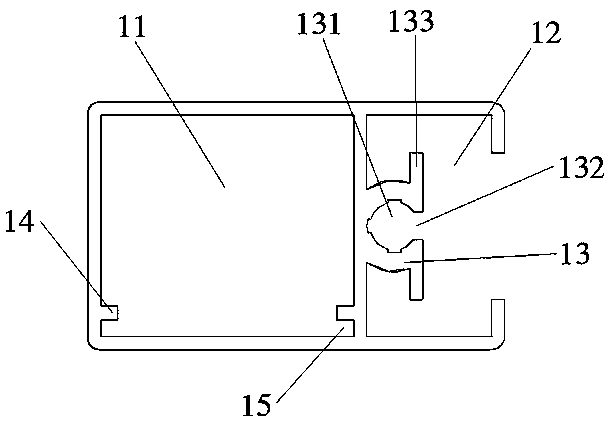

[0039] The first frame 1 includes an abdominal cavity 11 and a slot 12, a screw connection portion 13 is provided in the abdominal cavity or the slot of the first frame 1, and the connecting screw 4 changes from the long side to the short side of the second frame 2 It extends in the direction to be connected with the screw connection portion 13 in the abdominal cavity or the slot of the first frame 1;

[0040] A mounting hole 3 is opened on the outer side wall of the second frame 2;

[0041] The structure of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com