Double-grade combined type planetary gear driving structure

A technology of planetary gear transmission and planetary gear, which is applied in the direction of gear transmission, transmission, belt/chain/gear, etc. It can solve the problems of affecting the service life of the reducer, large force at the end, obvious vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

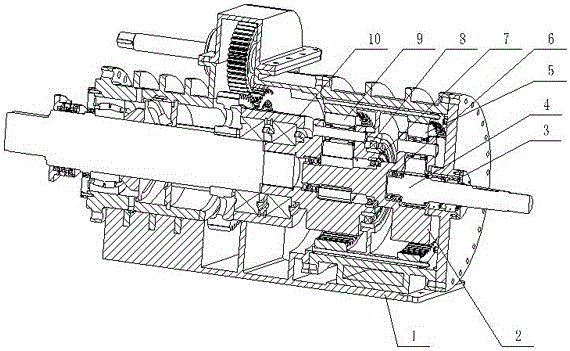

[0017] like figure 1 As shown, a two-stage combined planetary gear transmission structure includes a casing 1 and its internal first-level planetary gear structure and second-level planetary gear structure. The left end of the input shaft 4 enters from the right side of the casing 1 and then inserts the first-level planetary gear. The center of the gear structure is used as a primary sun gear and is connected with 5 teeth of each primary planetary gear. The input shaft 4 is provided with a bearing 3 where it enters the casing 1. The rotating shaft of each primary planetary gear 5 is respectively fixed to the right end of the primary planet carrier 2. Connection, the left end of the primary planetary carrier 2 is inserted into the center of the secondary planetary gear structure as the secondary sun gear and is connected with the teeth of each secondary planetary gear 9, and the rotating shaft of each secondary planetary gear 9 is fixedly connected to the secondary planetary car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com