Overhanging shaft positioning structure and motor transmission structure

A technology of positioning structure and motor transmission, applied in the field of transmission, can solve the problems of metal sleeve 3, such as high processing accuracy and alignment assembly requirements, non-recoverable pits, complex assembly process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described below based on examples, but the present invention is not limited to these examples.

[0025] The outrigger shaft positioning structure in the present application can be used for positioning all outrigger shafts bearing loads, which can reduce wear and increase the service life of the entire structure.

[0026] For the convenience of description, the outrigger shaft positioning structure in the present application will be described below by taking the outrigger shaft of a motor as an example.

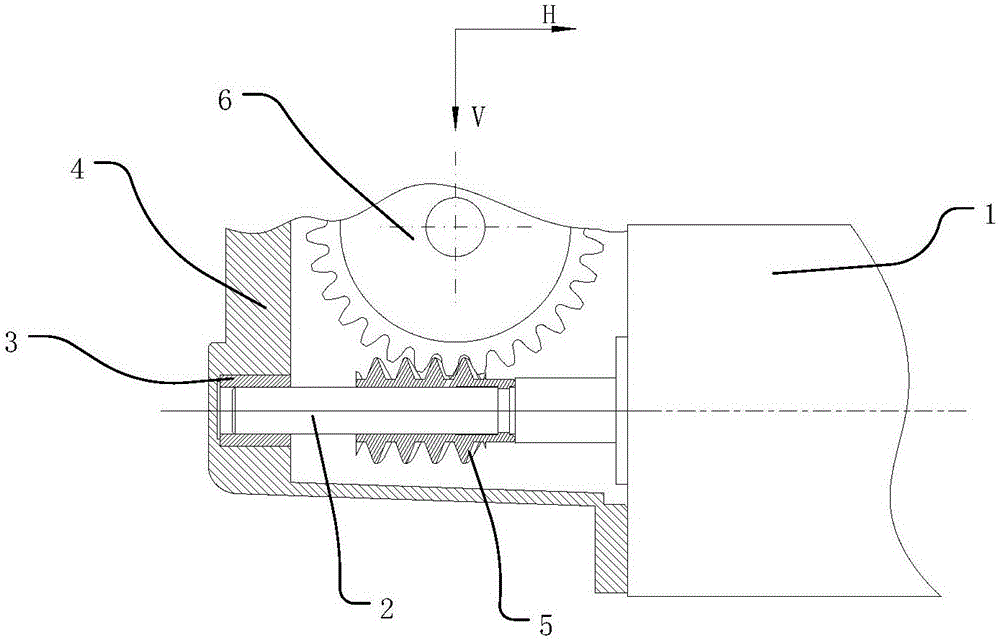

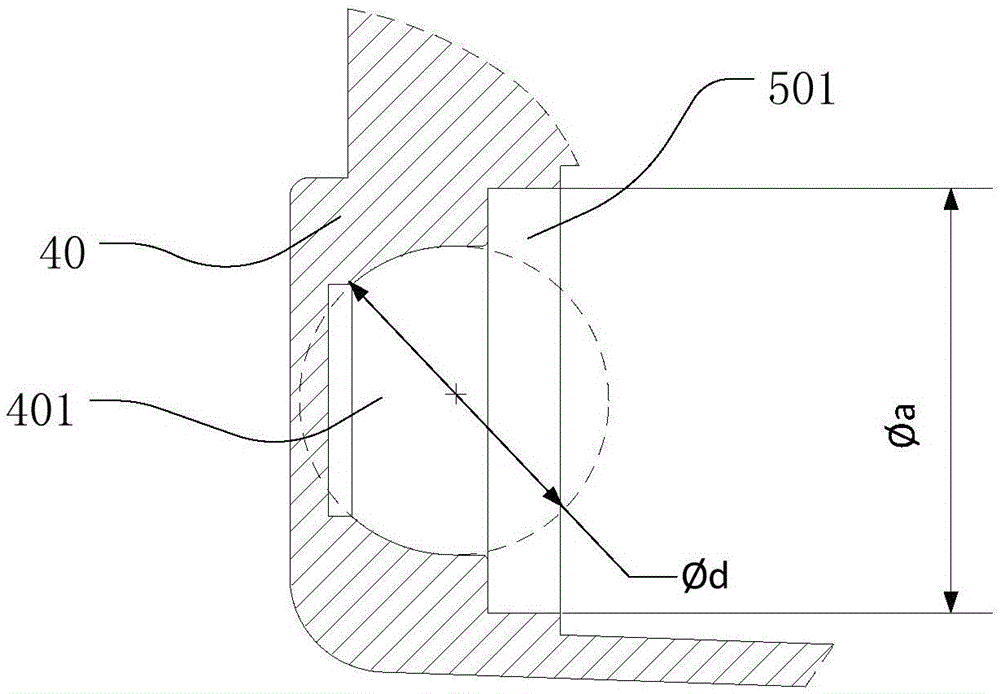

[0027] Such as Figure 2-3 As shown, the motor 10 has an extension shaft 20, one end of the extension shaft 20 is internally connected with the motor 10, and the other end is a free end. In the present application, the free end of the extending shaft 20 is connected with the fixing member 40 . The fixing member 40 can position and fix the free end of the outwardly extending shaft 20 . The fixing member 40 may be, for example, a box of a trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com