System and method for generating electricity by means of temperature difference of heat pipe

A technology of thermoelectric power generation and thermoelectric power generation sheets, which is applied to generators/motors, collectors, electric vehicles, etc., and can solve problems such as inability to maintain a high temperature difference, inability to solve power generation efficiency, and low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

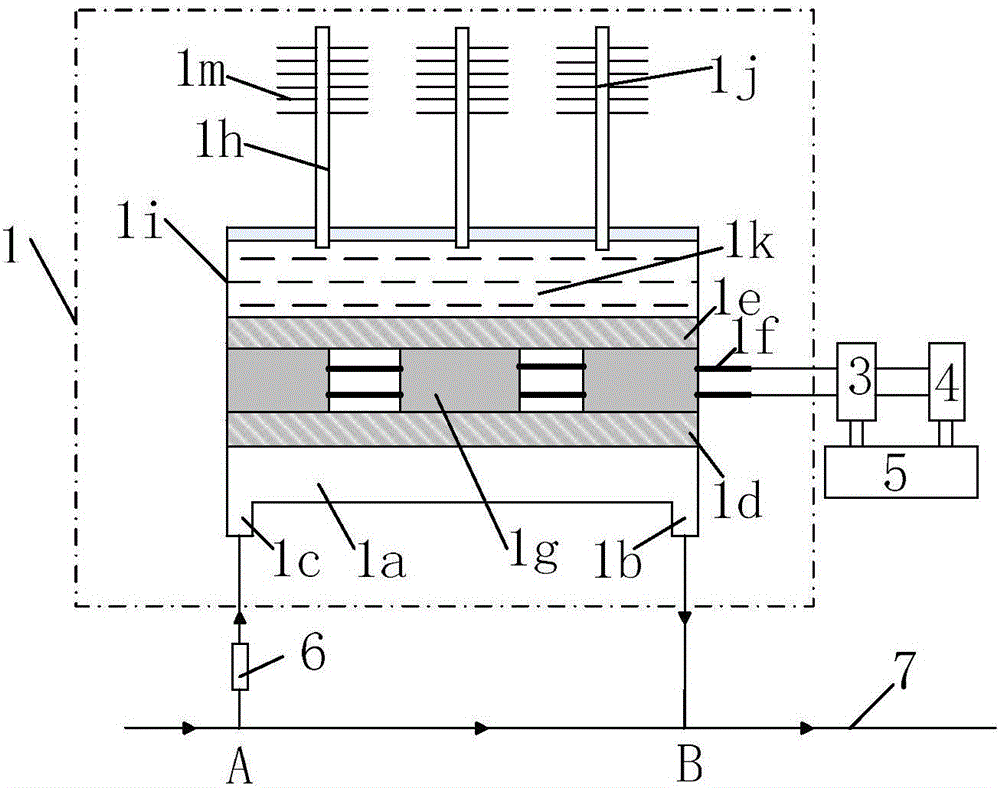

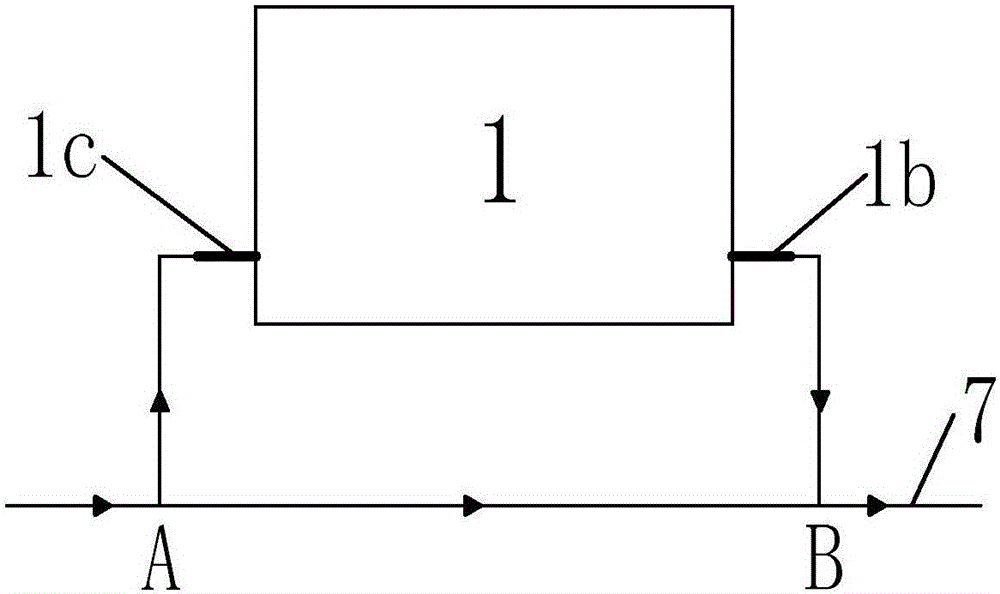

[0068] Example 1: Participation figure 1 with figure 2 .

[0069] A system that utilizes heat pipe temperature difference to generate power, mainly used for power supply for temperature and pressure monitoring instruments in heating pipe wells, including: thermoelectric power generation system 1, control circuit 3, power storage device 4, equipment that needs power supply 5, high-temperature pipeline 7 and cooling source environment. The high-temperature pipeline 7 is the water supply pipeline of the heating system, and the cold source environment is the air environment outside the tube well. Among them, the temperature difference between cold and heat of the thermoelectric power generation system comes from the high-temperature pipeline and the cold source environment with a certain temperature difference. The thermoelectric power generation system 1 supplies power to the equipment 5 through the control circuit 3 .

[0070] Specifically, such as figure 1 with figure 2...

Embodiment 2

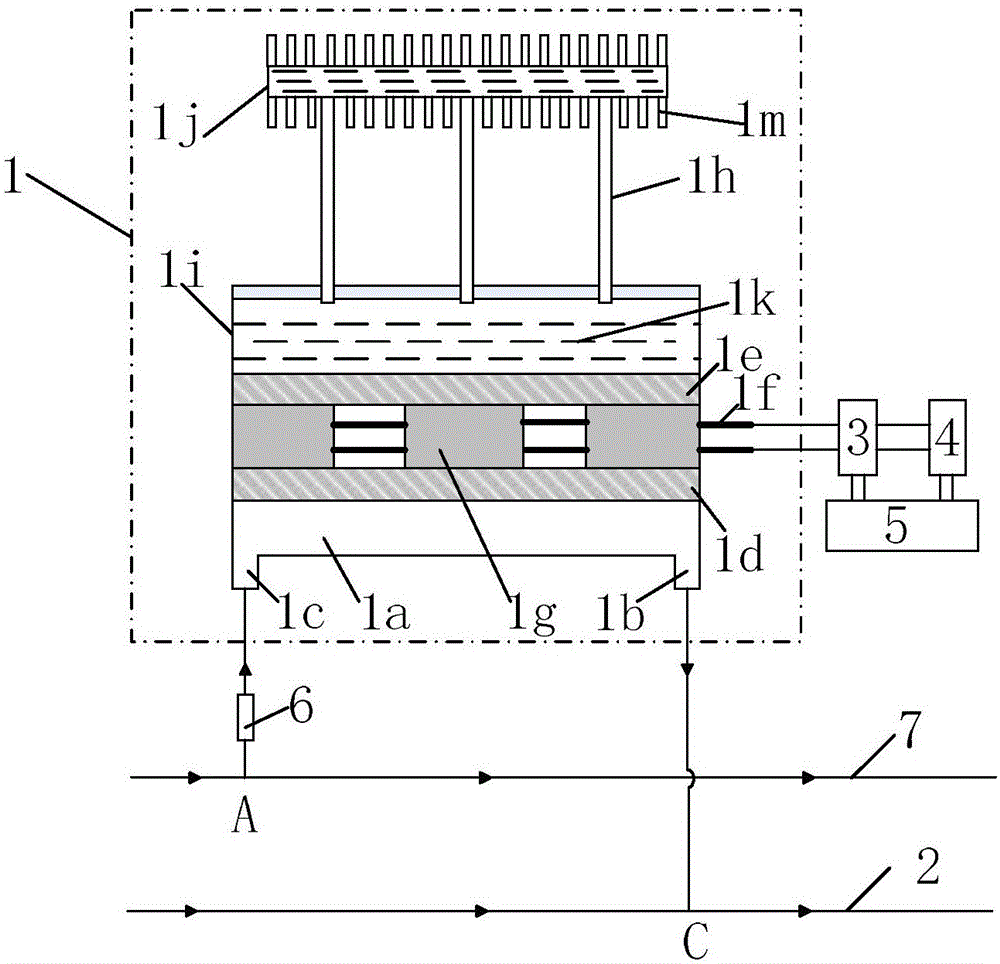

[0075] Example 2: Participation image 3 with Figure 4 .

[0076] A system that utilizes heat pipe temperature difference to generate power, mainly used for power supply for temperature and pressure monitoring instruments in heating pipe wells, including: thermoelectric power generation system 1, control circuit 3, power storage device 4, equipment that needs power supply 5, high-temperature pipeline 7, return Water pipeline 2 and cold source environment. The high-temperature pipeline 7 is the water supply pipeline of the heating system, and the cold source environment is the air environment outside the tube well. Among them, the temperature difference between cold and heat of the thermoelectric power generation system comes from the high-temperature pipeline and the cold source environment with a certain temperature difference. The thermoelectric power generation system 1 supplies power to the equipment 5 through the control circuit 3 .

[0077] Specifically, such as i...

Embodiment 3

[0083] Example 3: Participation Figure 5 .

[0084] A system that utilizes heat pipe temperature difference to generate power, mainly used for power supply for temperature and pressure monitoring instruments in heating pipe wells, including: thermoelectric power generation system 1, control circuit 3, power storage device 4, equipment that needs power supply 5, high-temperature pipeline 7 and cooling source environment. The high-temperature pipeline 7 is the water supply pipeline of the heating system, and the cold source environment is the air environment outside the tube well. Among them, the temperature difference between cold and heat of the thermoelectric power generation system comes from the high-temperature pipeline and the cold source environment with a certain temperature difference. The thermoelectric power generation system 1 supplies power to the equipment 5 through the control circuit 3 . Specifically, such as Figure 5 As shown, the thermoelectric power gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com