A connecting rod type hot pot scooper

A connecting rod type, hot pot technology, applied in the direction of plug-in, etc., can solve the problems such as difficult to popularize and use, lowering, and scalding of soup, and achieve the effect of convenient food sandwiching, lower use cost, and simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

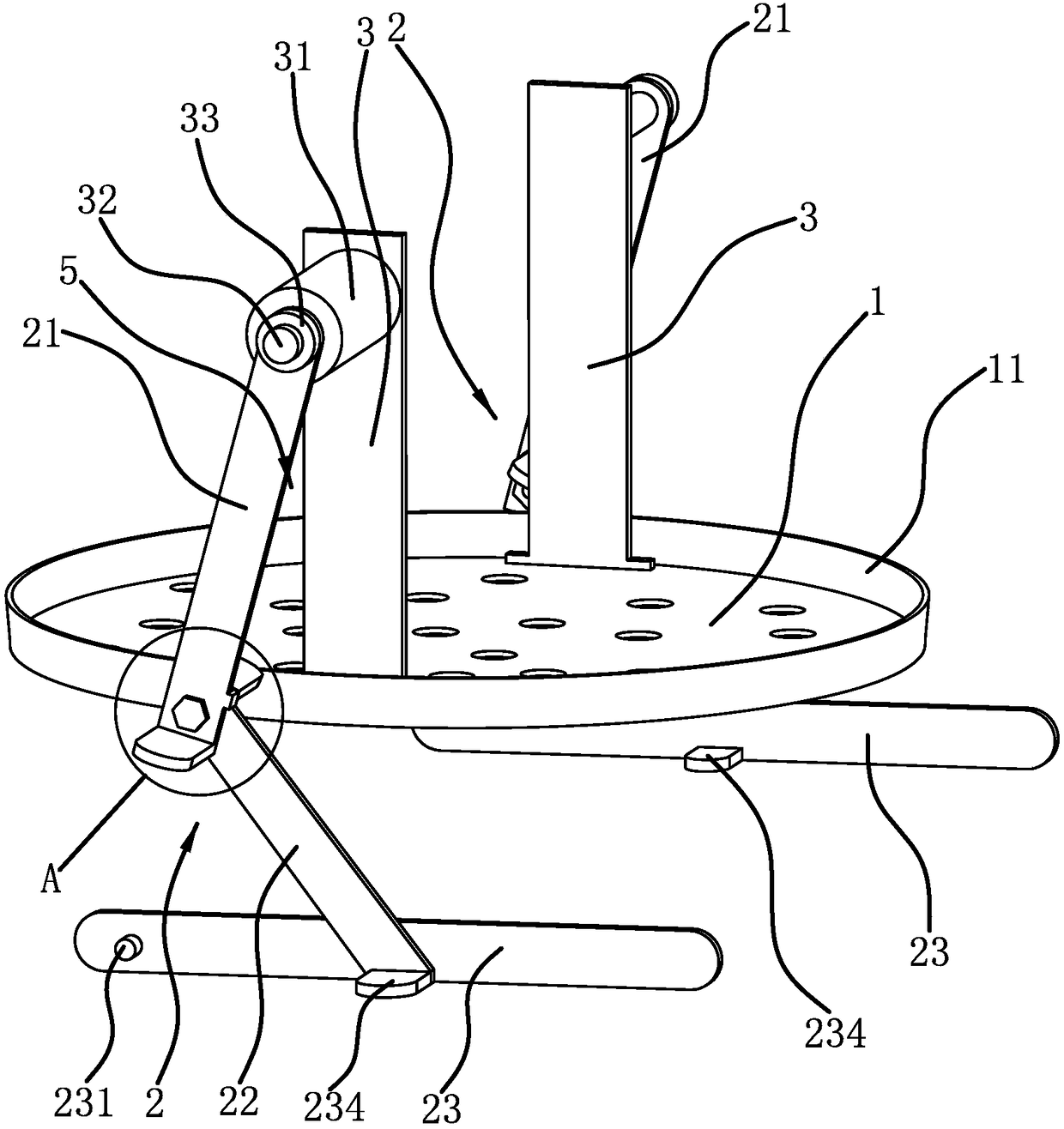

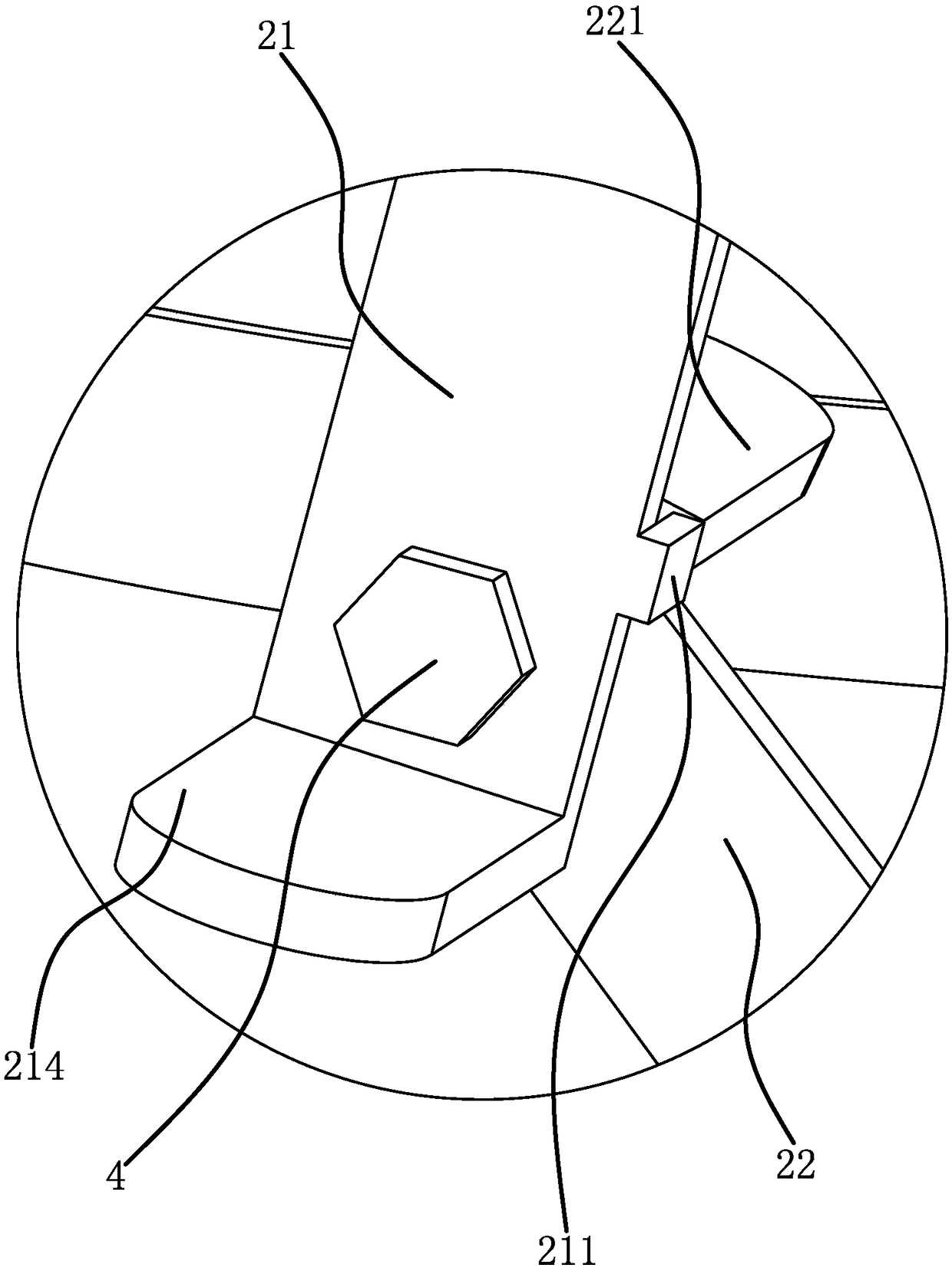

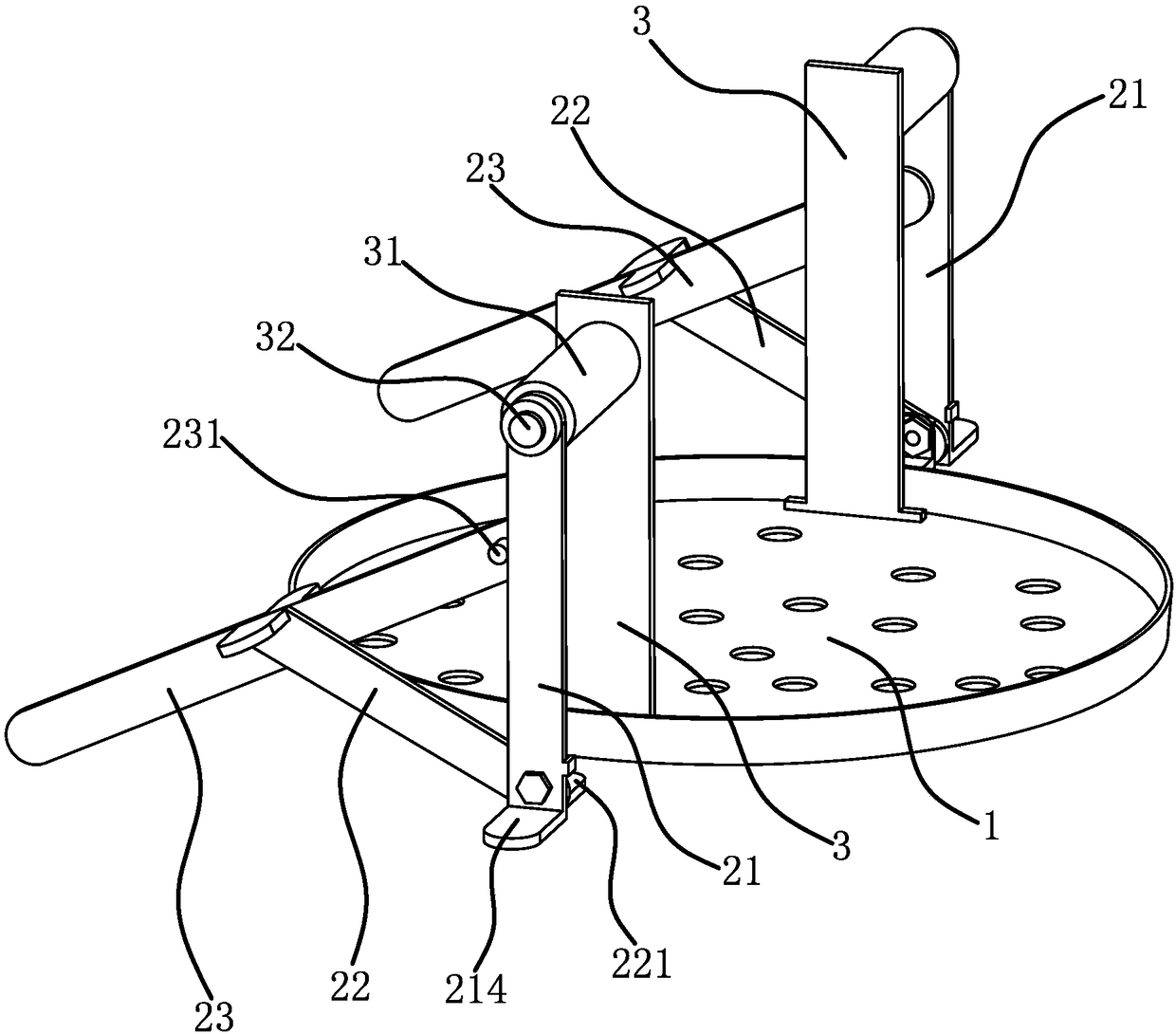

[0032] Such as figure 1 , figure 2 , image 3 As shown, a connecting rod type chafing dish scooper comprises a filter plate 1, which is circular and submerges into the chafing dish body 6, and the edge of the upper side of the filter plate 1 has a flanging 11 in the circumferential direction. Both sides of the filter plate 1 are symmetrically provided with a support assembly 2, the support assembly 2 includes an upper adjustment rod 21, a lower adjustment rod 22, a support rod 23 and a connecting shaft 32, the connecting piece 3 is in the shape of a long strip, and the connecting piece 3 The lower end of the connecting piece 3 is fixedly connected with the filter plate 1, the upper end side of the connector 3 is vertically fixedly connected with the limit sleeve 31, one end of the connecting shaft 32 is fixedly plugged into the limit sleeve 31, and the upper end of the upper adjustment rod 21 is provided with a connection hole, the other end of the connecting shaft 32 passe...

Embodiment 2

[0037] The structure of this connecting rod type chafing dish scooper is basically the same as embodiment one, the difference is as Figure 10 As shown, the abutting member includes an abutting bolt 213, a connecting portion 212 is provided on the lower edge of the upper adjusting rod 21, and a screw hole is opened on the connecting portion 212, and the abutting bolt 213 is screwed in the screw hole, and the end of the abutting spiral When the lower adjustment rod 22 swings downward to the bottom of the upper adjustment rod 21 and the support rod 23 is horizontal, the upper end of the lower adjustment rod 22 is inclined to one side, and the upper end of the upper adjustment rod 21 is inclined to the other side, and The end of the bolt 213 is supported against the edge of the upper end of the lower adjusting rod 22 .

Embodiment 3

[0039] The structure of this connecting rod type chafing dish scooper is basically the same as embodiment one, the difference is as Figure 11 As shown, the support member includes a support protrusion 232 on the side of one end of the support rod 23, and a positioning groove 233 is provided on the support protrusion 232. The lower adjustment rod 22 swings upward to the side of the upper adjustment rod 21 and the other end of the support rod 23 When the end is on the same level as the lower end of the upper adjusting rod 21 , the edge of the upper adjusting rod 21 is embedded in the positioning groove 233 and the supporting protrusion 232 is supported against the upper adjusting rod 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com