Window glass sealing rubber strip production line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

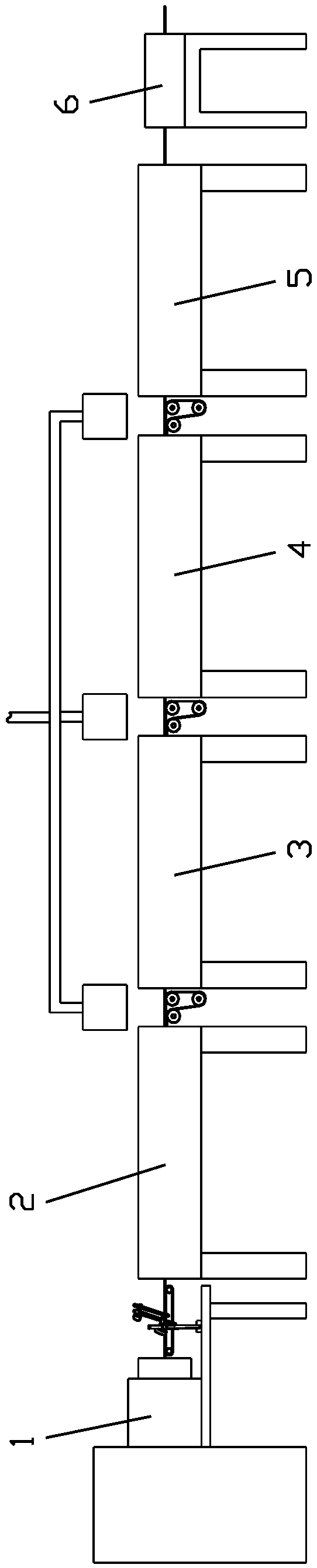

[0024] As shown in the figure, the window glass sealing rubber strip production line of this embodiment includes an extruder 1, a microwave vulcanizer 2, a surface sprayer 3, a hot air vulcanizer 4, a cooling device 5, and a tractor 6 arranged in sequence,

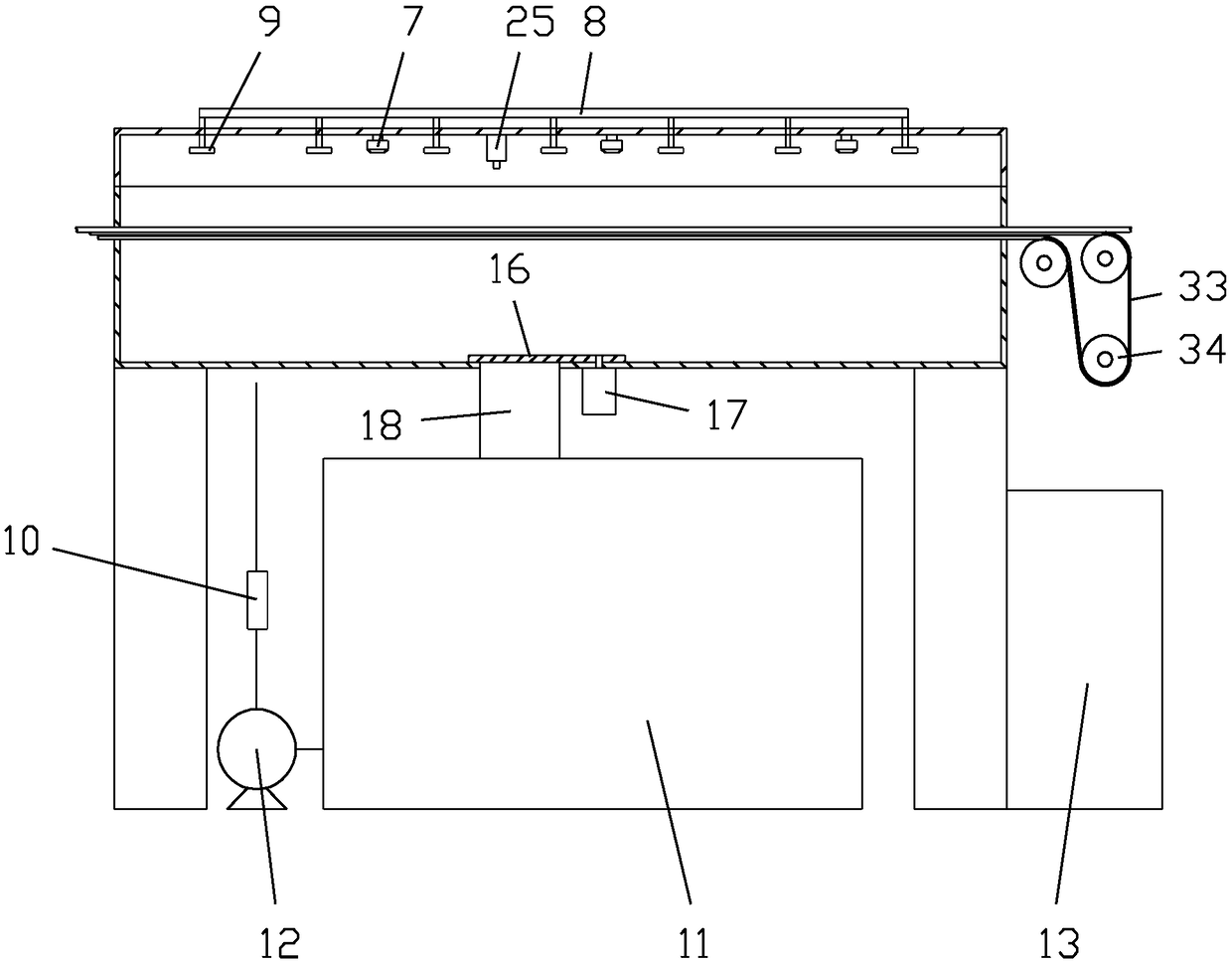

[0025] Both the microwave vulcanizer and the hot air vulcanizer are equipped with an automatic fire extinguishing device, which includes a smoke sensor 7, a first water pipe 8, a high pressure nozzle 9, a solenoid valve 10, a water storage tank 11, a first water pump 12 and a control Device 13, the smoke sensor is arranged on the inside top of the casing of the microwave vulcanizer and the hot air vulcanizer, the first water pipe is parallel to the rubber strip, the high-pressure nozzle is connected to the first water pipe and the high-pressure nozzle is located above the rubber strip; The water inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com