Automotive axle forging die spraying system

A technology for molds and axles, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve problems such as poor surface coverage, uneven thickness of the covering layer, and difficulty in controlling the amount of spraying , to avoid the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below with reference to the drawings and specific embodiments. The following embodiments are only descriptive and not restrictive, and the protection scope of the present invention cannot be limited by this.

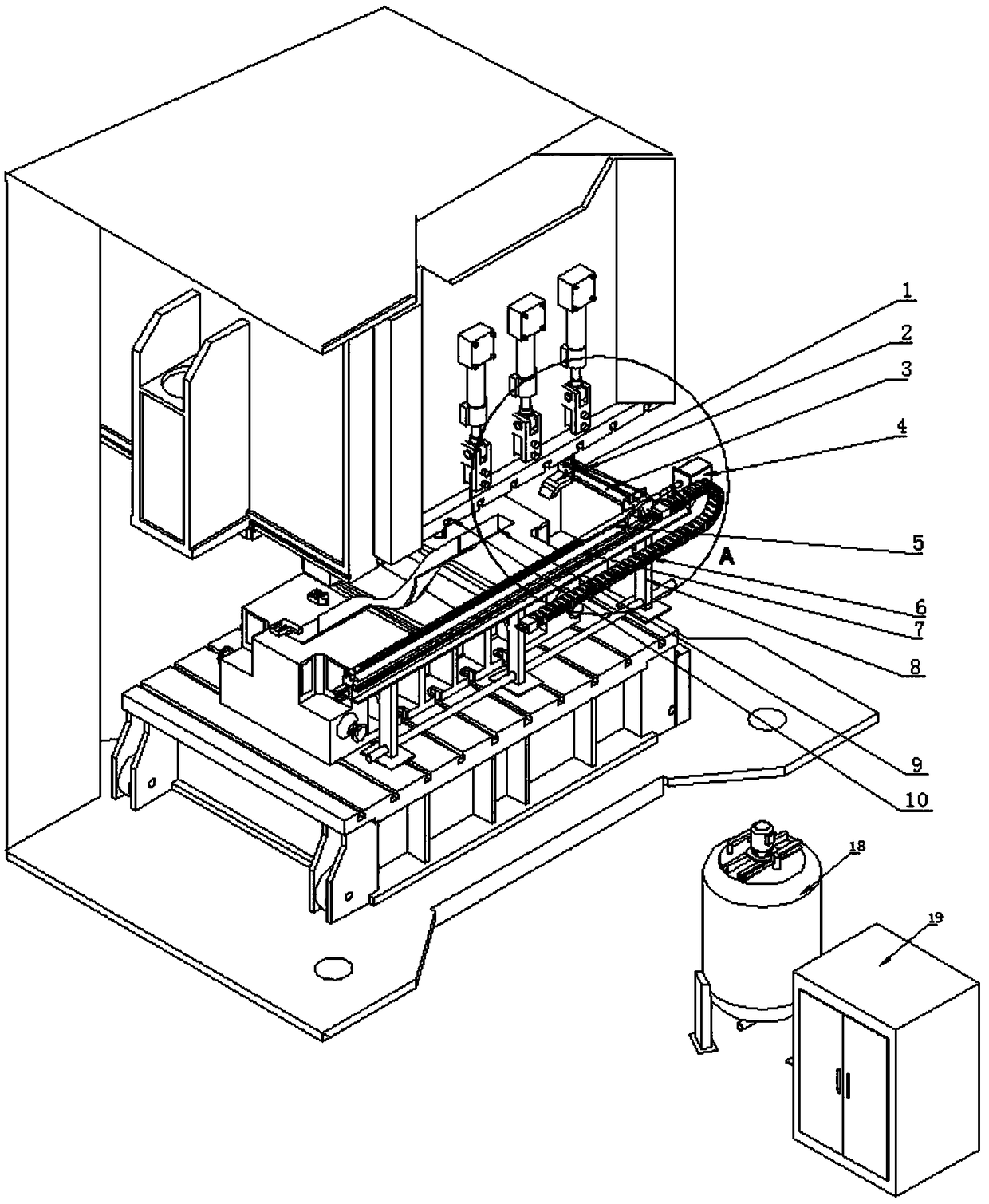

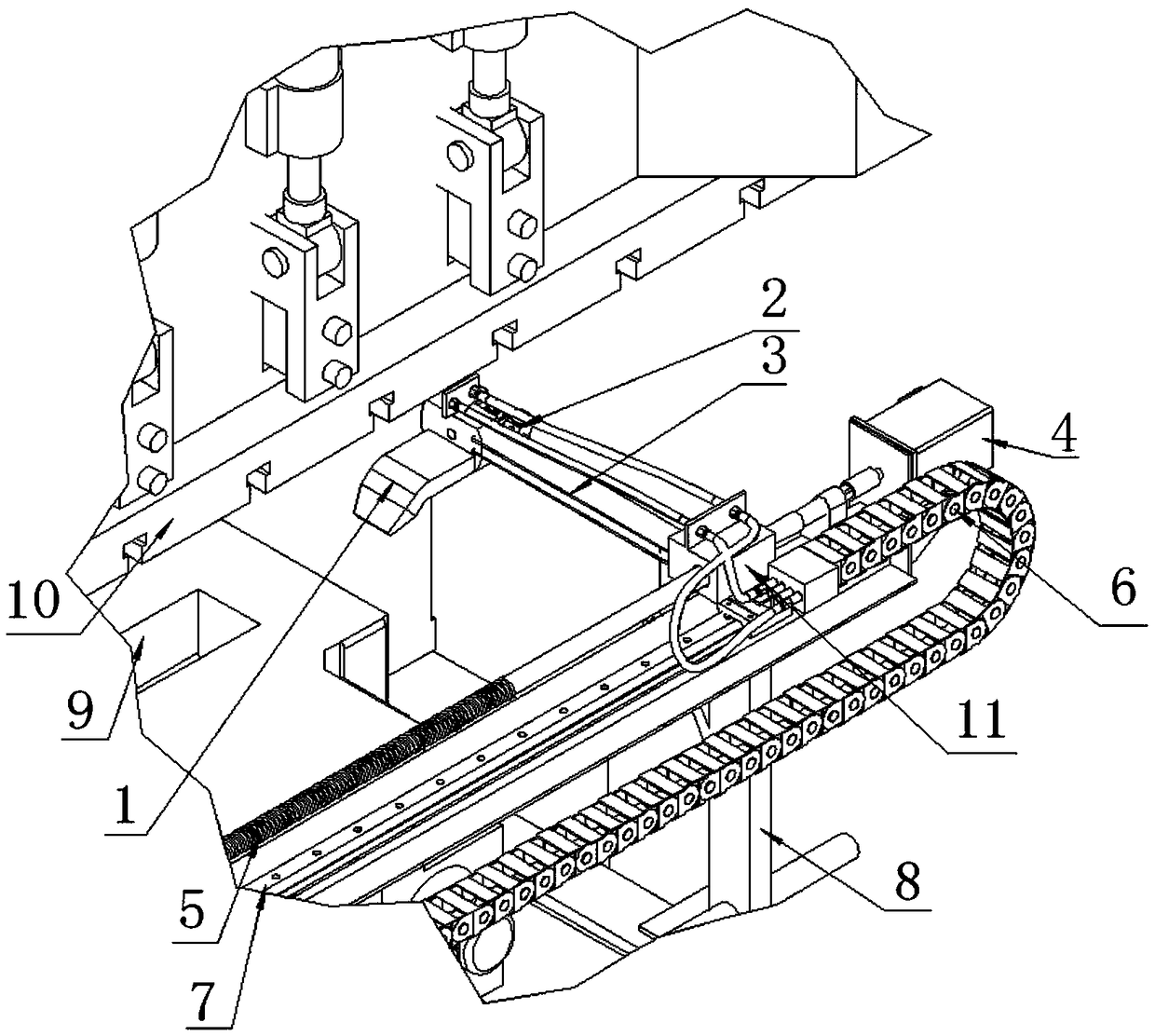

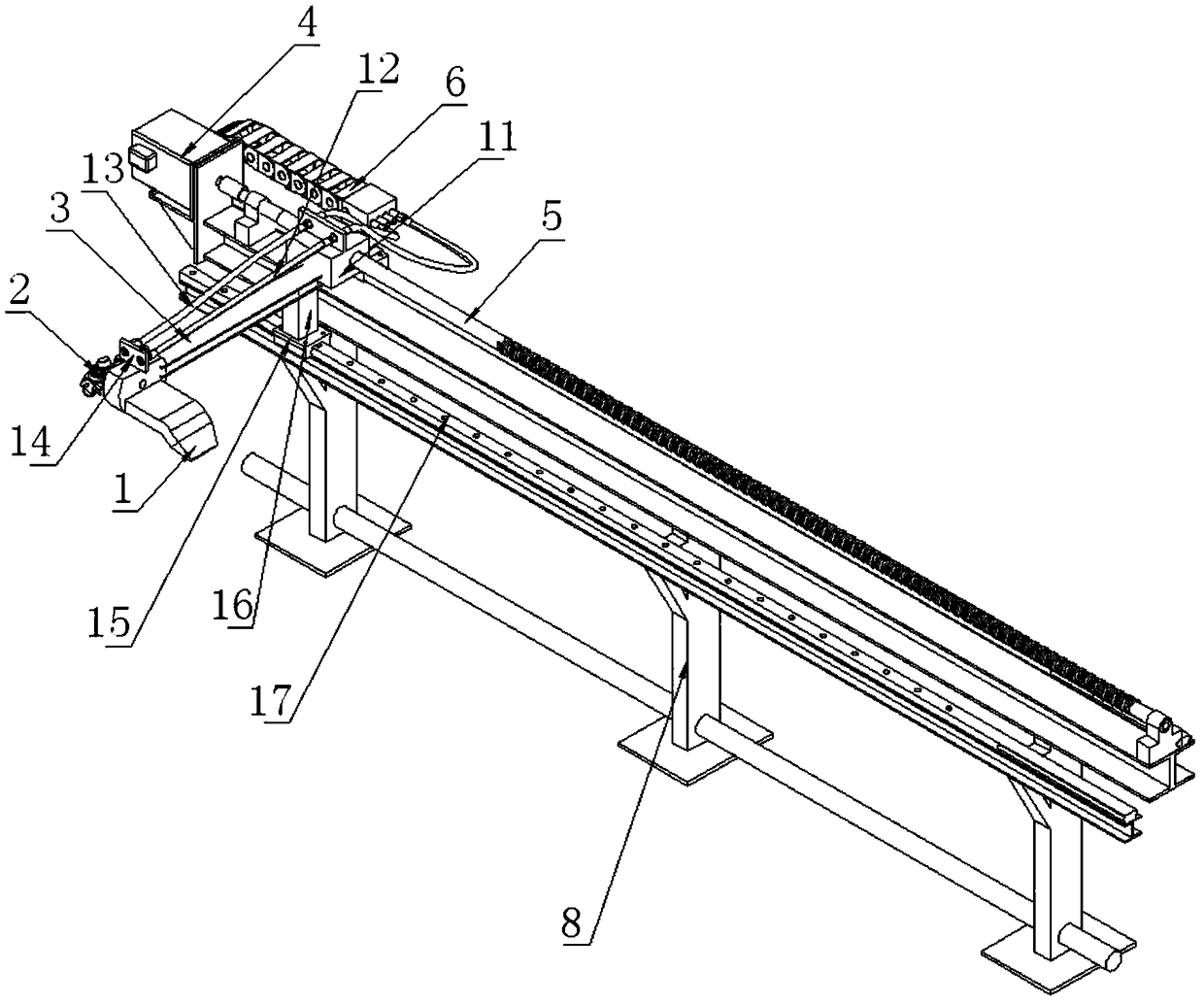

[0025] A spraying system for forging molds for automobile axles includes a liquid release agent storage tank 18; a release agent high-pressure delivery unit 19; a mobile atomizing spraying unit and an electrical control unit. The release agent storage tank is connected to the mobile atomization spraying unit through the release agent high-pressure delivery unit.

[0026] The agitator is installed on the cover of the release agent storage tank and is driven by a complete set of motor / reducer. In order to effectively control the liquid level in the tank, a set of ultrasonic sensors is installed on the cover of the tank. The display instrument can directly display the liquid level number.

[0027] The release agent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com