Fluorescent powder coating device and coating method utilizing same

A technology for coating device and phosphor powder, which is applied to devices for coating liquid on surfaces, coatings, pretreatment surfaces, etc., to achieve the effects of wide industrial application prospects, improved consistency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

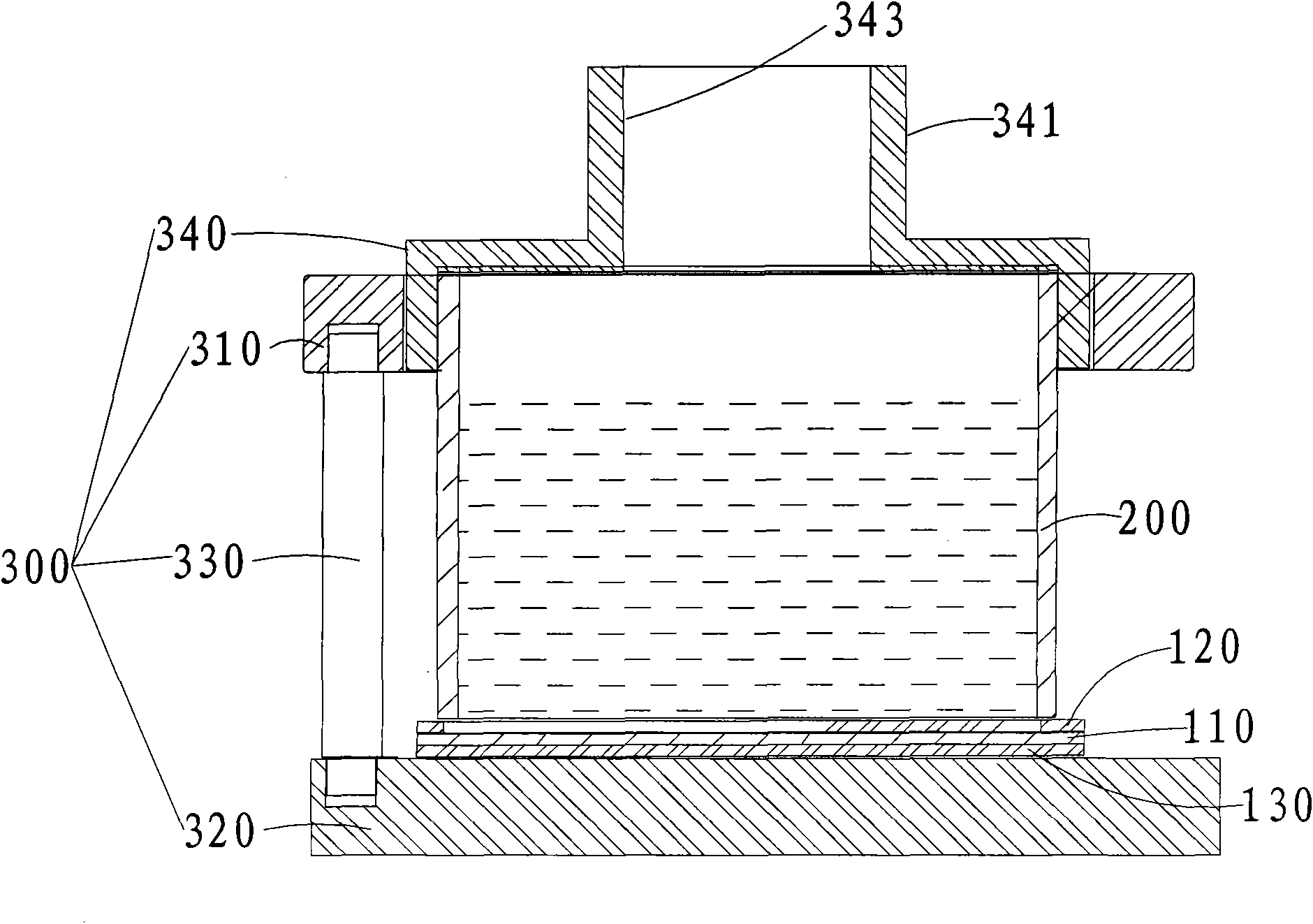

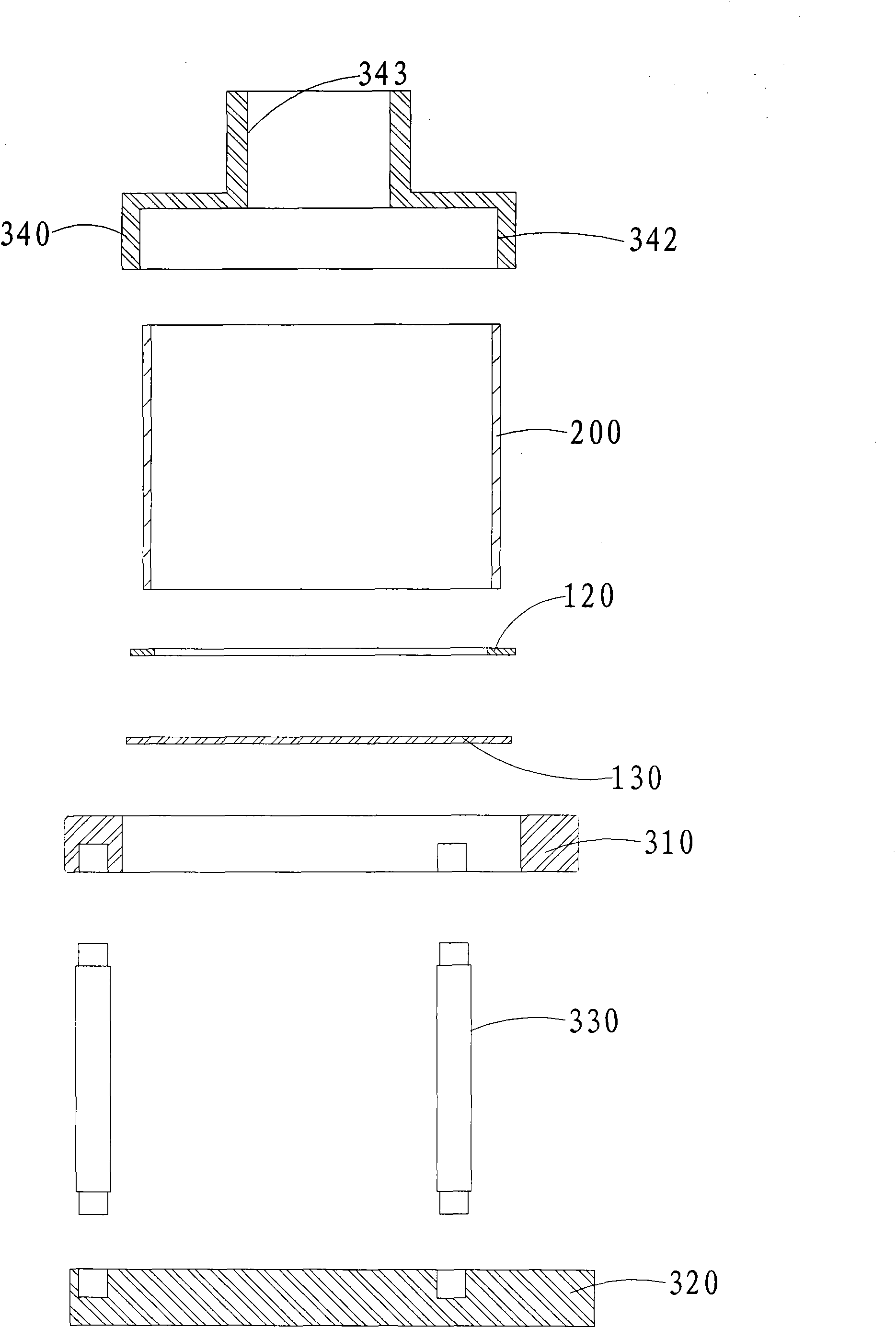

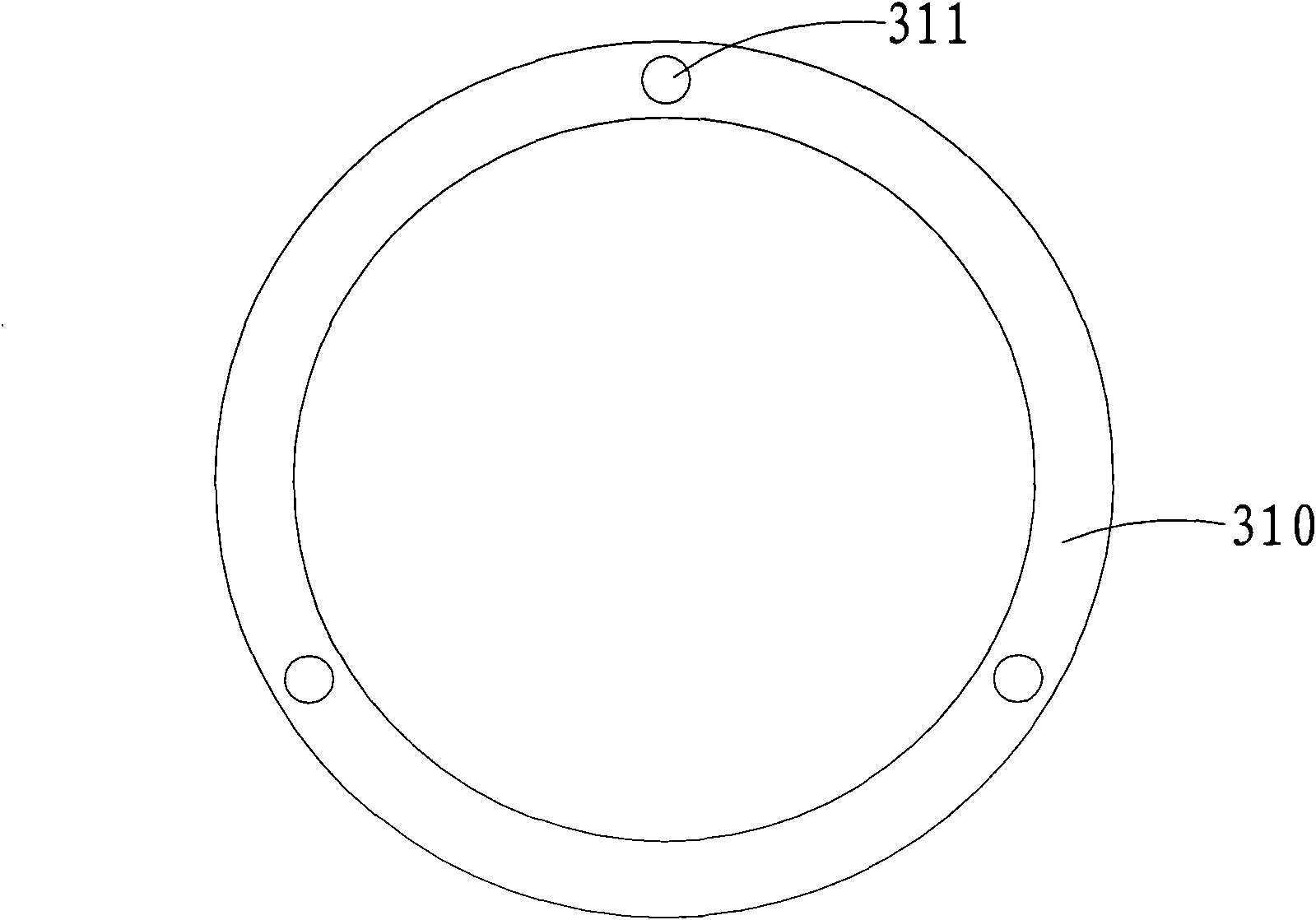

[0026] Specifically, such as figure 1 and figure 2 As shown, the pressing part 300 includes a supporting column 330, a lower base plate 320 located at the lower end of the pressing part 300 and a fixing ring 310 located at the upper end of the pressing part 300, the lower base plate 320 and the fixing ring 310 are arranged at intervals in parallel to The container cylinder 200 is reliably pressed into the frame assembly to prevent the dispersion liquid in the container cylinder 200 from leaking out. The fixed ring 310 and the lower base plate 320 are fixedly connected by the support column 330, and the container cylinder 200 is arranged on the bottom of the lower base plate 320. Above, the pressing member 300 also includes a pressing cover 340 that is connected to the fixing ring 310 and can compress the container barrel 200. Specifically, the pressing cover 340 is screwed to the fixing ring 310, so as to facilitate Fixing and taking out of the container cartridge 200. In ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com