Method for improving thermal conductivity of viscous medium based on warm-hot forming of viscous medium

A viscous medium, warm forming technology, applied in the field of improving the thermal conductivity of viscous medium, can solve the problems of reduced plate production efficiency, long heating preparation time of viscous medium, low thermal conductivity of viscous medium, etc., to shorten the heating preparation time and improve production efficiency Improved, high thermal conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

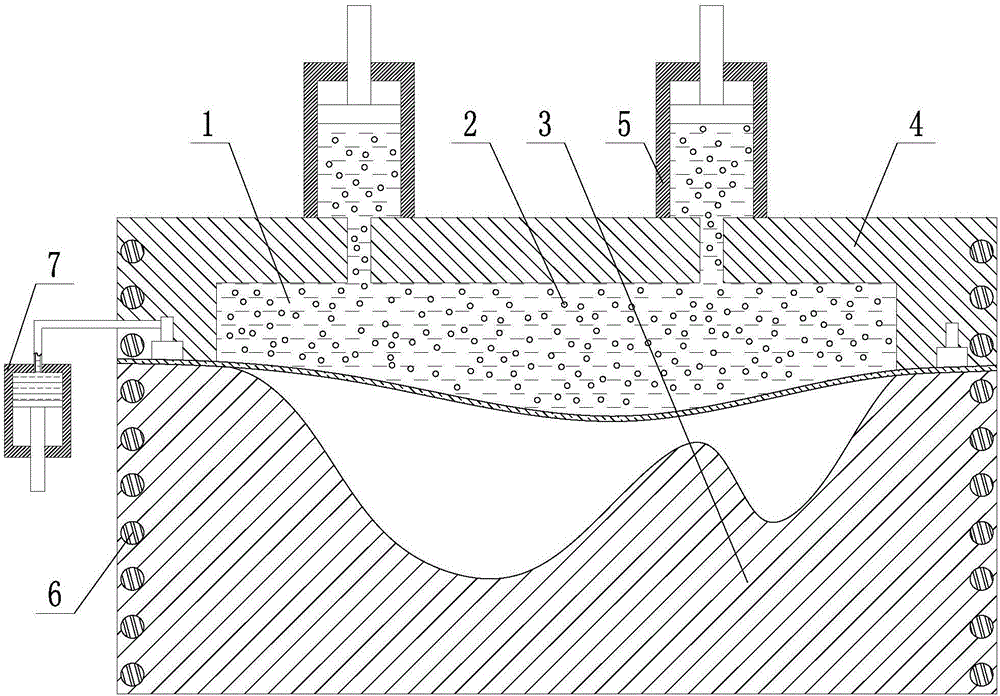

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] A method for improving the thermal conductivity of a viscous medium based on warm forming of the viscous medium, comprising the steps of:

[0022] Step 1: Prepare a particle with a higher thermal conductivity than the viscous medium, and set the particle size value of the particle and the mass percentage of the particle to the viscous medium; the value range of the particle size is nanometer, micron or Millimeter level, the range of the mass percentage of particulate matter and viscous medium is 10% to 50%;

[0023] Step 2: Prepare a transparent container and put the viscous medium into the measuring cup;

[0024] Step 3: Add the particles into the measuring cup filled with viscous medium;

[0025] Step 4: Evenly mix the particles in the measuring cup with the viscous medium;

[0026] Step 5: Send the measuring cup containin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com