Structure and preparation method of a phosphogypsum slag discharge yard

A technology for phosphogypsum and slag discharge yards, which is applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding workshops, etc., and can solve the problems of shortening the belt frame, belt service life, high risk factor for slag discharge operators, and adaptability of the belt machine frame In order to achieve the effect of reducing input cost, reducing slope height and reducing risk factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

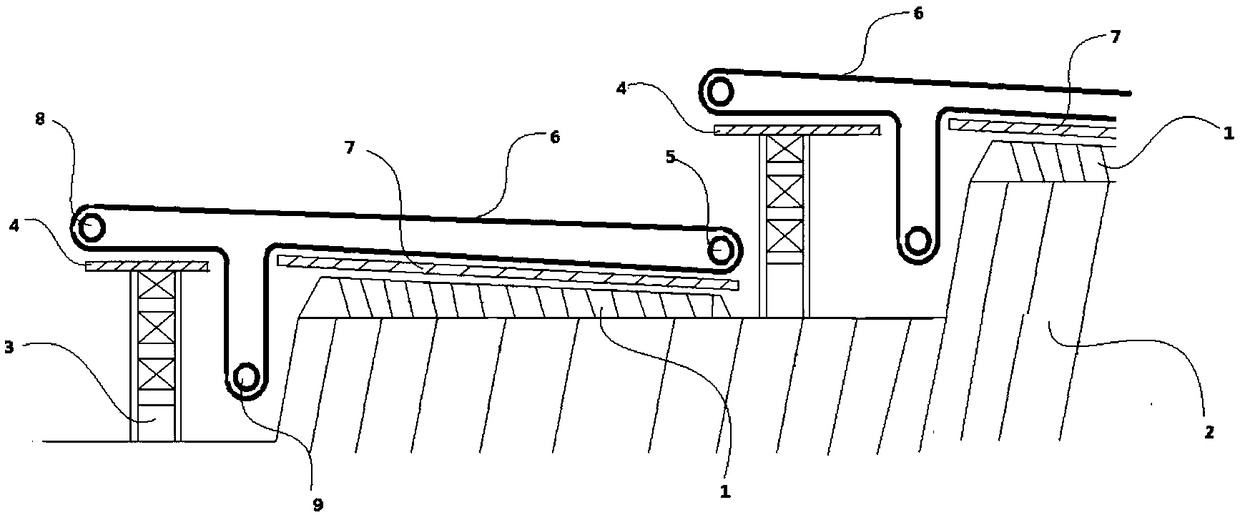

[0037] Such as figure 1 As shown, a structure of a phosphogypsum slag discharge yard is provided with a base layer 2, and the base layer 2 is stepped. On the same step of the base layer 2, a rolling layer 1 and a high tower 3 are arranged, and the rolling layer 1 is located on the high Before the tower 3, the upper surface of the rolling layer 1 is laid with a prefabricated slab 7; there is a gap between the rolling layer 1 and the high tower 3 on the next step, and forms a pit together with the base layer 2; the top of the high tower 3 is provided with a Platform 4; the prefabricated plate 7 is provided with a first motor 5 near the end of the high tower 3 on the same ladder, a third motor 9 is provided in the above-mentioned pit, and a first motor 9 is provided on the platform 4 directly opposite to the first motor 5. Two motors 8, the first motor 5, the second motor 8, and the third motor 9 are connected by a conveyor belt 6. During the slag discharge process, the conveyor...

Embodiment 2

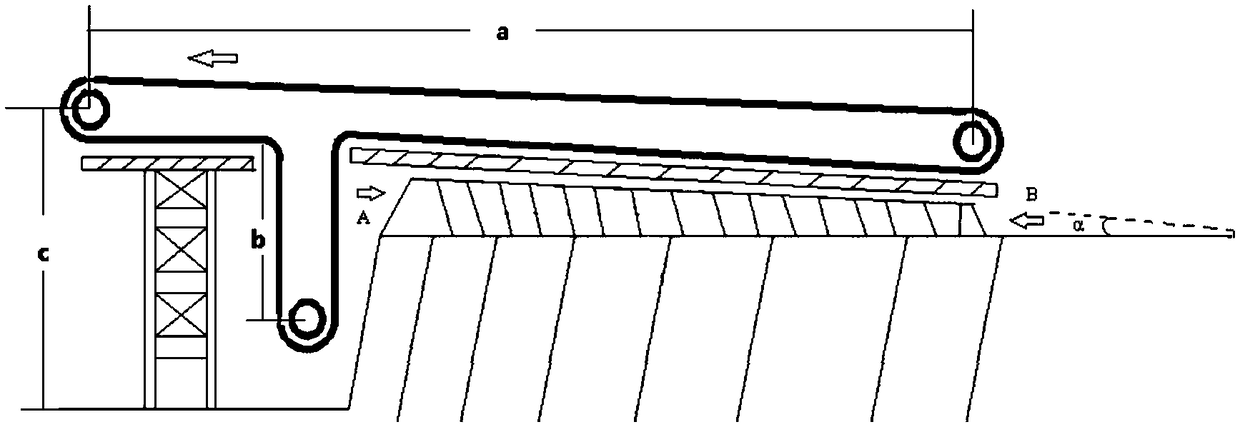

[0039] Such as figure 2 Shown, on the basis of embodiment 1, others are all the same as embodiment 1, a kind of structure of phosphogypsum slag discharge yard, described rolling layer 1 is inclined to the high tower 3 ends on the same ladder, and with The horizontal plane of the base layer 2 forms an included angle α. The size of the included angle is determined by the structure of the rolling layer, especially by the length of the rolling layer, and the height g of the rolling layer near the end of the high tower and the height e away from the end of the high tower 3 are stable and determined , when the length of the laminated layer is longer, the included angle will be smaller.

[0040] In addition, in the process of determining the included angle, it can also be determined by the thickness of the rolling layer after determining the length of the rolling layer.

Embodiment 3

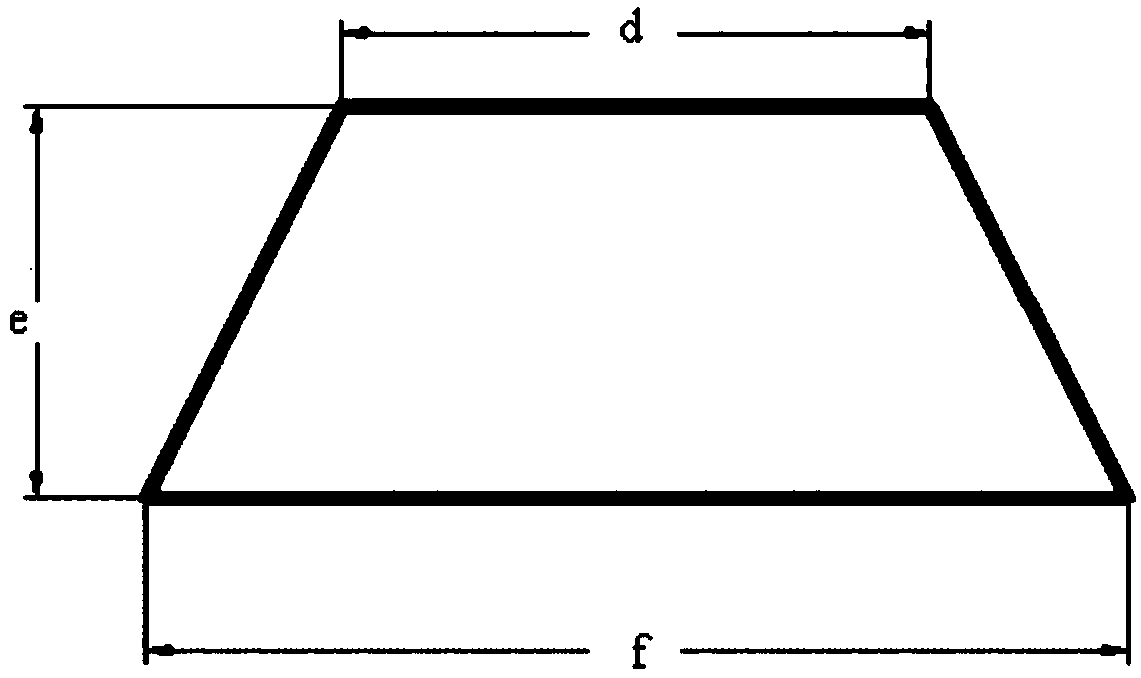

[0042] Such as figure 2 , 3 , 4, on the basis of embodiment 1, others are all the same as embodiment 1, a structure of a phosphogypsum slag discharge yard, the end face of the high tower 3 ends of the described rolling layer 1 close to the same ladder is trapezoidal , the length f of the lower bottom is 8m, the length d of the upper bottom is 6m, and the height g is 1.5m; 6m, height e is 4m. The pit is 10m deep; the third motor 9 is arranged on the bottom of the pit. The distance b from the center of the third motor 9 to the horizontal plane of the platform 4 is 8m. The step horizontal distance c from the center of the second motor 8 to the base layer 2 is 12m. The distance a between the center of the first motor 5 and the center of the second motor 8 is 80m. The length of the rolling layer 1 is 60-70m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com