Composition, optical film including the composition, and method of producing the optical film

一种组合物、光学膜的技术,应用在光学膜领域,能够解决温度困难等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

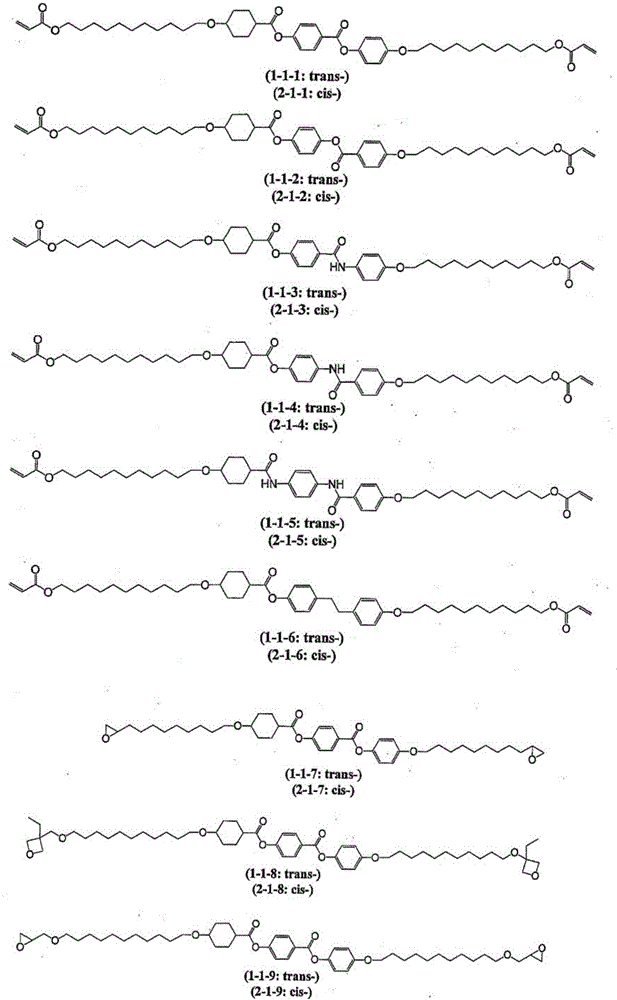

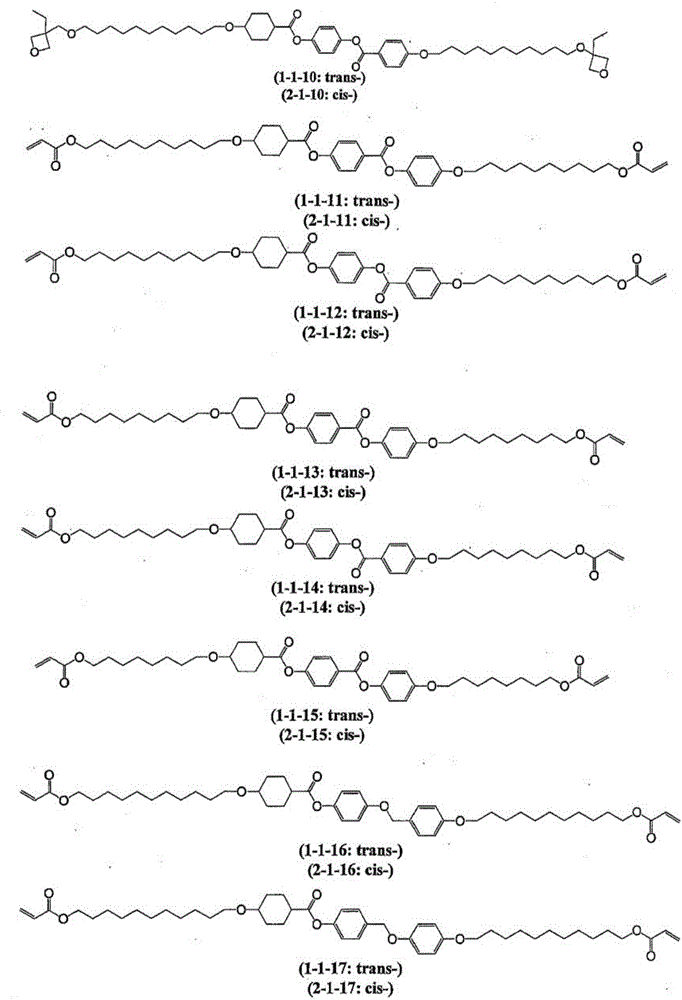

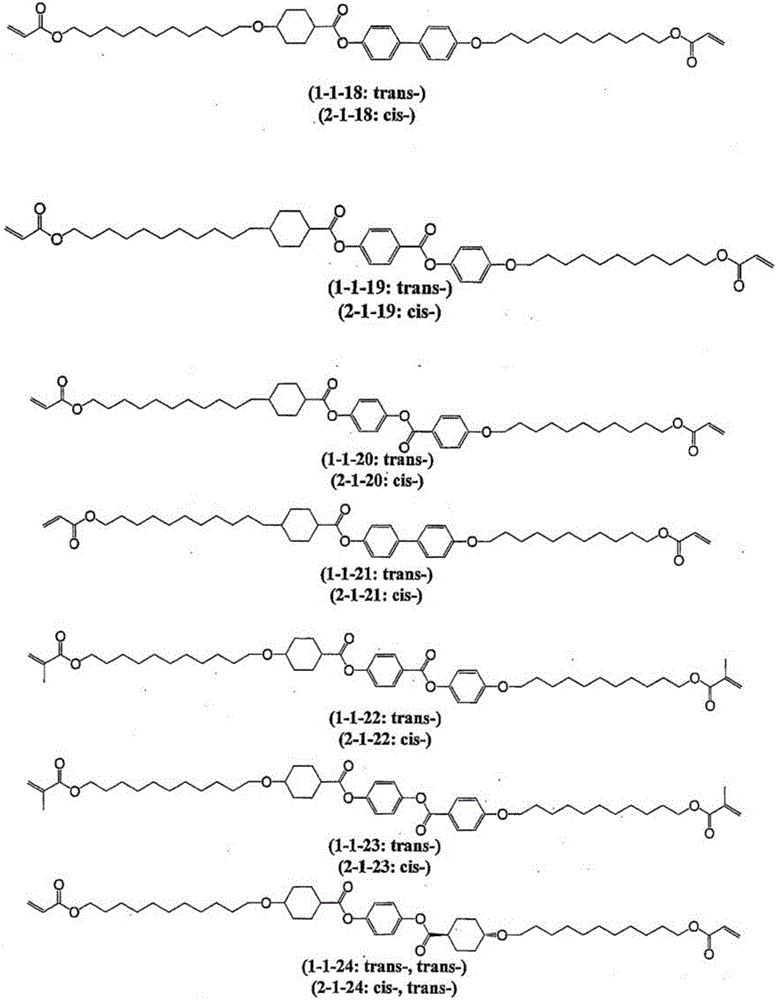

[0068] [Embodiment 1: Composition]

[0069] The present invention is a composition containing a smectic liquid crystal compound having a 1,4-cyclohexyl group, wherein the smectic liquid crystal compound having a 1,4-cyclohexyl group contains a smectic liquid crystal compound having a trans-1,4-cyclohexyl group ( Hereinafter, it may be referred to as "trans-isomer"), and a smectic liquid crystal compound having a cis-1,4-cyclohexyl group (hereinafter, may be referred to as "cis-isomer"). The content of the cis-isomer is 0.1 to 10 parts by mass relative to 100 parts by mass of the trans-isomer. Preferably it is 0.3 mass part or more, More preferably, it is 0.5 mass part or more, More preferably, it is 0.7 mass part or more, Still more preferably, it is 1 mass part or more. Moreover, it is preferably 7 parts by mass or less, and more preferably 5 parts by mass or less. By making the content of the cis-isomer 10 parts by mass or less relative to 100 parts by mass of the trans-is...

Embodiment approach 2

[0210] [Embodiment 2: Optical film]

[0211] The optical film of the present invention is formed from a composition containing a smectic liquid crystal compound having a 1,4-cyclohexyl group or the liquid crystal composition described above. That is, this invention may be an optical film containing the said composition containing the said liquid crystal composition, or the said liquid crystal composition. In addition, when the above-mentioned smectic liquid crystal compound contained in the composition of the present invention or constituting the above-mentioned liquid crystal composition and the geometric isomer of the smectic liquid crystal compound have a polymerizable group, the optical film of the present invention may contain An optical film of a polymer of the smectic liquid crystal compound and a polymer of the geometric isomer of the smectic liquid crystal compound.

[0212] The optical film can be obtained by curing a composition or a liquid crystal composition that...

Embodiment approach 3

[0216] [Embodiment 3: Manufacturing method of optical film]

[0217] The present invention may be a method for producing an optical film including the following steps (1) to (3).

[0218] (1) The process of coating the composition of the present invention on a substrate;

[0219] (2) The process of heating the composition coated on the substrate;

[0220] (3) The process of cooling the heated said composition to 30 degreeC or less so that a smectic liquid crystal orientation may be performed.

[0221] In the step (1), it is preferable to adjust the viscosity (fluidity) of the composition by, for example, dissolving the composition in an organic solvent before coating the composition of the present invention on the resin substrate. By adjusting the viscosity of the composition, the composition can be uniformly coated on the resin substrate, and the unevenness in the thickness of the resulting optical film can be reduced.

[0222] In the step (1), the method of applying the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com