Aluminum formwork installation process

An installation process and aluminum formwork technology, which is applied in the direction of formwork/formwork/work frame, formwork/formwork components, and on-site preparation of building components, which can solve the problems of irregular management and use, high process cost investment, and weak technical force and other issues, to achieve the effect of saving labor, significant environmental benefits, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

[0029] A kind of aluminum template installation process described in the present invention, comprises the following steps:

[0030] (1) Prepare templates: In order to save production time and improve production efficiency, aluminum templates of specific shapes are directly purchased from the market and processed into aluminum templates of specified shapes;

[0031] (2) Construction site preparation: set-out and leveling work on site, lay out positioning bars, and then carry out steel bar binding and pipeline pre-embedding;

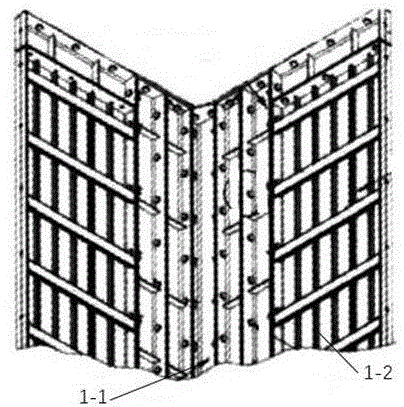

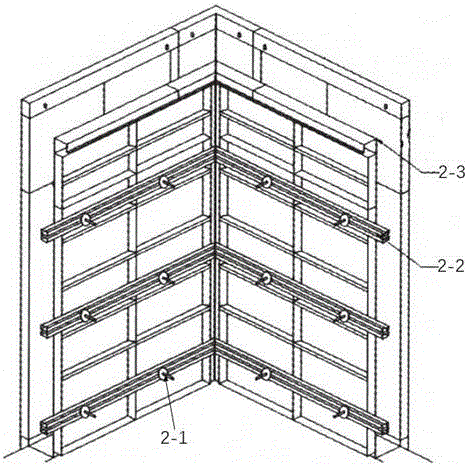

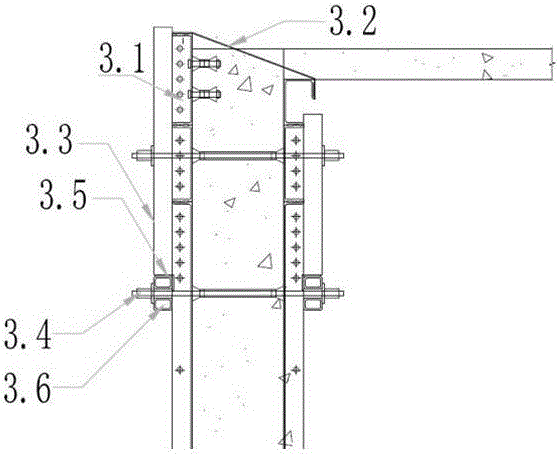

[0032] (3) First install the column wall formwork, then install the corner formwork and the beam formwork, and finally install the floor formwork and some node formwork. During the installation, use square holes and tension screws for reinforcement, and the aluminum formwork is installed. Finally, before pouring concrete, check the following aspects: e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com