A kind of growth method of zno single crystal nano sheet

A growth method, single crystal nanotechnology, applied in the field of nanomaterial growth and preparation, can solve problems such as unfavorable integration of integrated circuit technology, and achieve the effects of high temperature resistance, physical and chemical properties, smooth structure surface, and weak binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

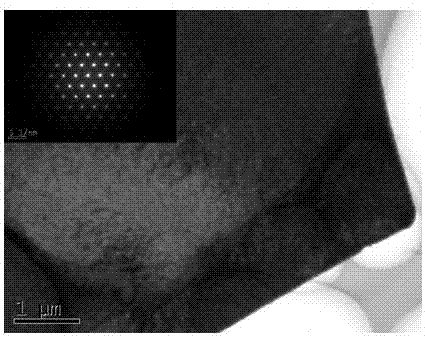

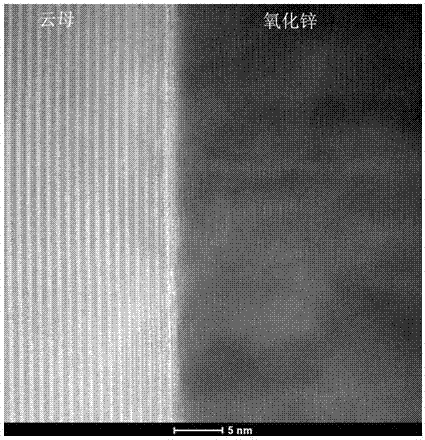

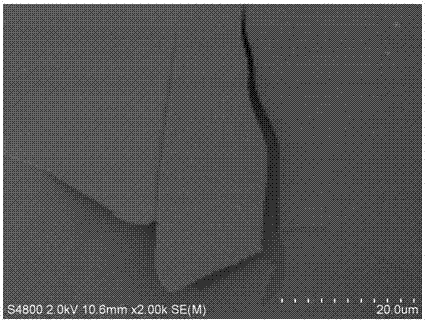

Embodiment 1

[0029] Fix the freshly cleaved fluorophlogopite substrate on a substrate holder and quickly load it into a pulsed laser deposition (PLD) vacuum chamber. The cavity air pressure is pumped to 10 -3 Below Pa, the substrate is heated to 550°C, and a 248nm pulse laser of 200mJ / pulse is used to focus on the ZnO ceramic target surface with a purity of 99.99%. The pulse frequency is 5Hz, and the deposition time is half an hour. 2 Anneal to room temperature at ambient. Depend on figure 1 The diffraction pattern of transmitted electron beam incident from ZnO [001] direction can be seen, and the diffraction pattern of ZnO single crystal can be clearly seen. The pattern is clear and regular, and the spots are complete. From figure 2 The high-resolution transmission electron micrographs of ZnO and mica show a good epitaxial relationship, and the interface is clear without amorphous transition layer. Depend on image 3 The scanning electron microscope shows that the size of single cr...

Embodiment 2

[0031] Fix the freshly cleaved fluorophlogopite substrate on the substrate holder and quickly put it into the PLD vacuum chamber. The cavity air pressure is pumped to 10 -3 Below Pa, heat the substrate to 450°C, use 200mJ / pulse 248nm pulsed laser to focus on the ZnO ceramic target surface with 99.99% purity, the pulse frequency is 5Hz, the deposition time is half an hour, and then in 3Pa O 2 Anneal to room temperature at ambient.

Embodiment 3

[0033] Fix the freshly cleaved fluorophlogopite substrate on the substrate holder and quickly put it into the PLD vacuum chamber. The cavity air pressure is pumped to 10 -3Below Pa, heat the substrate to 350°C, use 200mJ / pulse 248nm pulsed laser to focus on the ZnO ceramic target surface with 99.99% purity, the pulse frequency is 5Hz, the deposition time is half an hour, and then in 3Pa O 2 Anneal to room temperature at ambient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com