Excavation drill high in precision and efficiency

A high-efficiency, high-efficiency drill bit technology, applied in the direction of drill bits, drilling tools, drilling equipment, etc., can solve the problems of high cost of use, frequent replacement of drill bits, short service life, etc., to achieve reduced maintenance costs, convenient and fast maintenance, and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

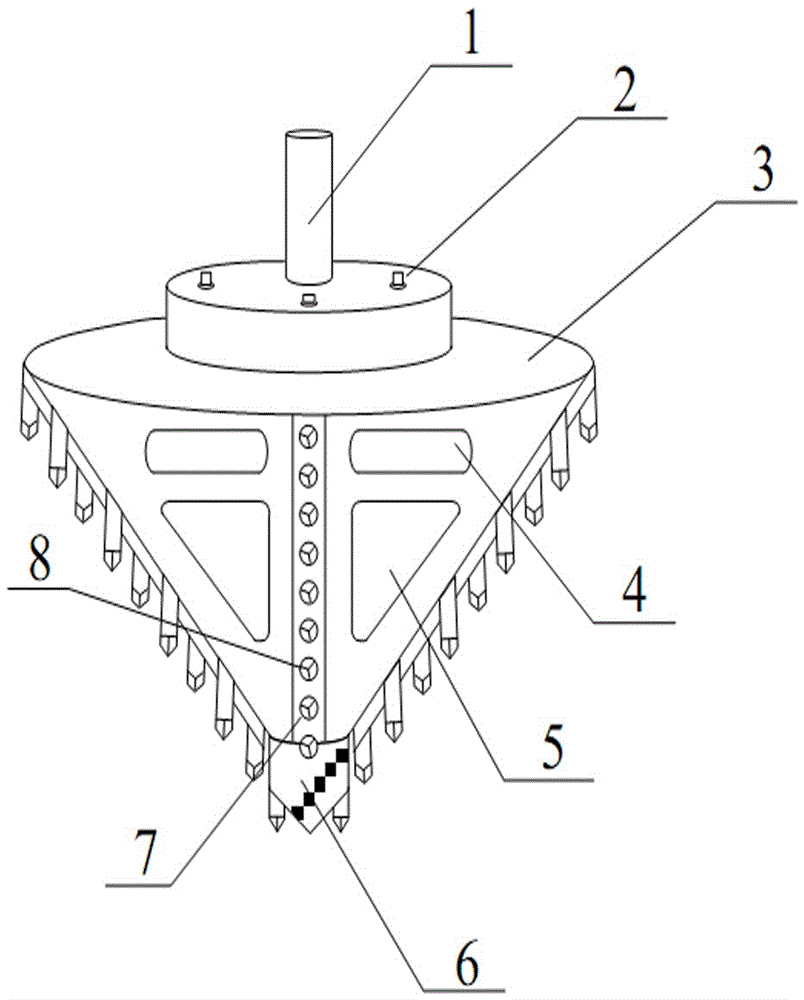

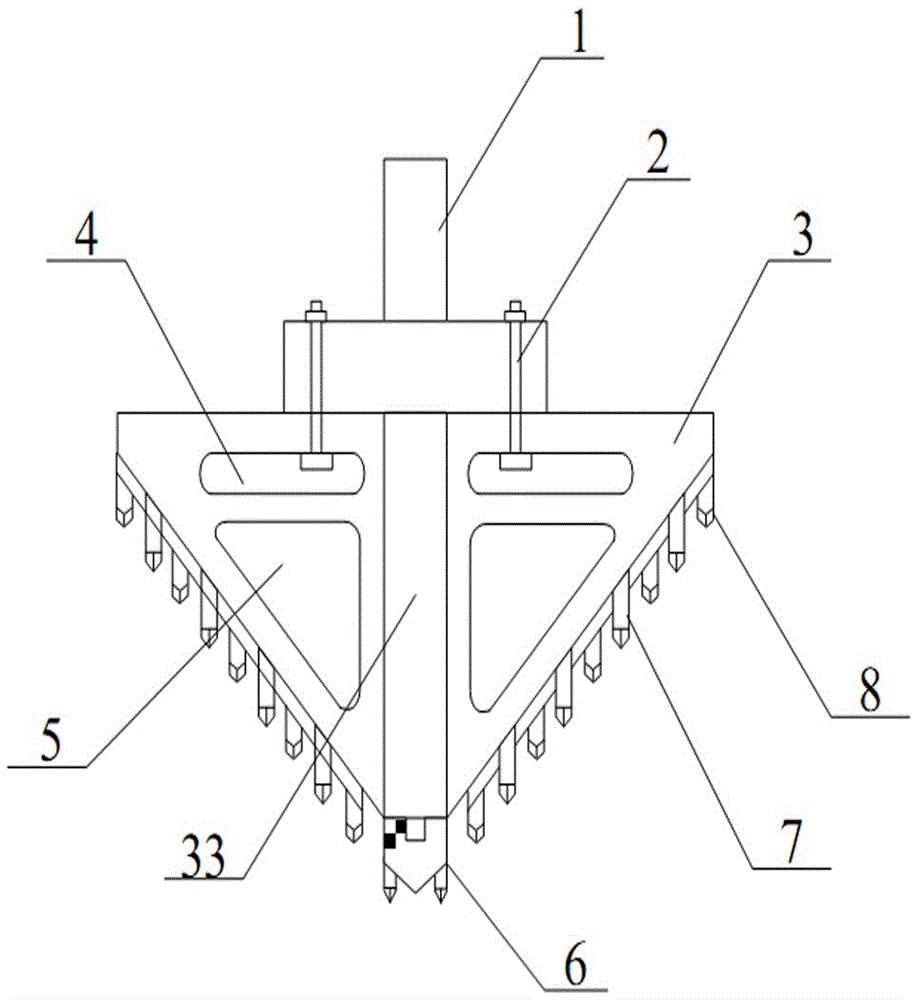

[0024] As attached figure 1 Attached Figure 4 Shown:

[0025] The present invention provides an excavating drill bit with high precision and high efficiency, comprising a connecting device 1, a fixing bolt 2, a drilling structure 3, a mounting slot 4, a heat dissipation window 5, a center drill bit 6, a main drill bit 7 and an auxiliary drill bit 8. The said connection The device 1 is installed on the upper part of the drilling structure 3 through the fixing bolts 2; the installation groove 4 is arranged on the upper part of the outer side of the drilling structure 3; the heat dissipation window 5 is arranged on the lower part of the installation groove 4; the center bit 6 Installed at the bottom of the drilling structure 3; the main drill bit 7 or the auxiliary drill bit 8 is installed on the outer side of the drilling structure 3.

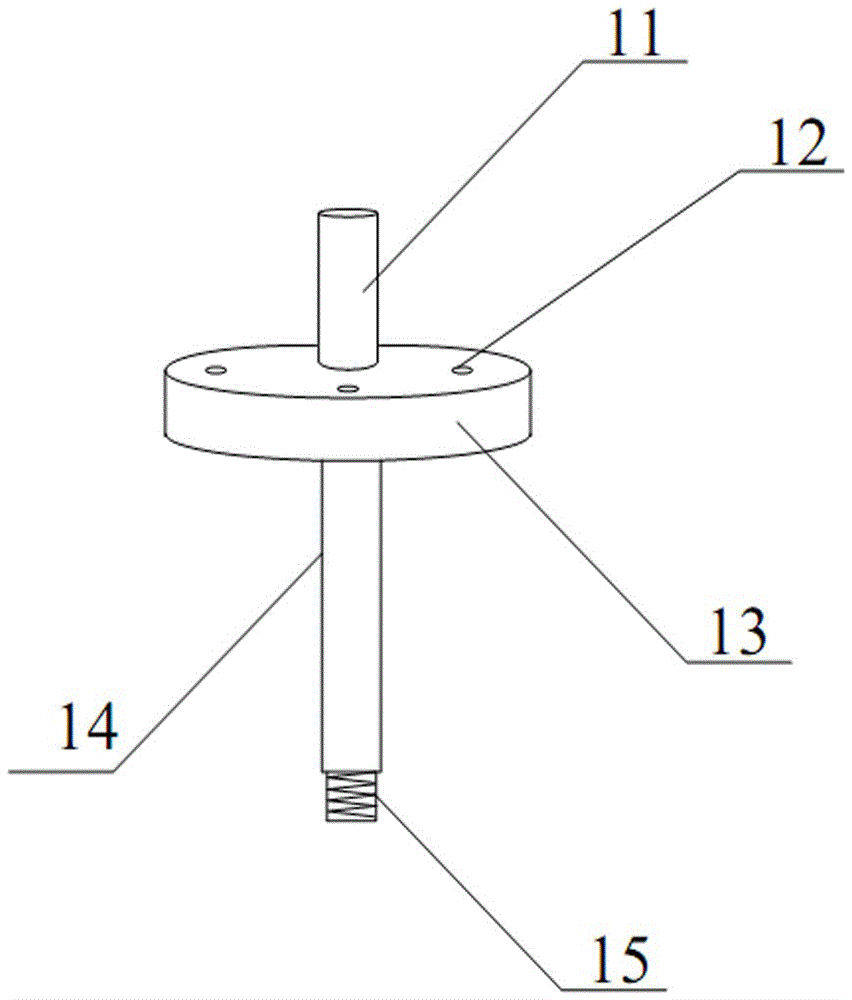

[0026] The connecting device 1 includes a connecting rod 11, a first connecting hole 12, a connecting base 13, a central shaft 14 and a threaded he...

Embodiment 2

[0034] The present invention provides an excavating bit with high precision and high efficiency. When the present invention is used, first insert the central shaft 14 of the connecting device 1 into the central cavity 33 of the drilling structure 3, and connect the first connecting hole 12 on the base 13 Align with the second connecting hole 32 on the drill boom body 31, install the fixing bolt 2 into the first connecting hole 12 and the second connecting hole 32 through the mounting slot 4, and lock and fix it, and then install the center drill 6 Insert the threaded head 15 at the bottom of the central shaft 14 and screw it firmly; finally, the main drill bit 7 and the auxiliary drill bit 8 are installed in the mounting hole 35 on the mounting plate 34, and then connected to the excavation drive device through the connecting rod 11 .

[0035] The present invention is realized in this way.

[0036] When the present invention is in use, it is connected to the excavation driving dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com