Ball screw with ball returning device and electric parking brake with ball screw

A ball screw and ball technology, applied in the direction of transmission, brake actuator, belt/chain/gear, etc., can solve the problems of reducing efficiency, improving sliding parts, increasing wear of balls and thread channels, etc., to reduce wear, Simple structure and novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

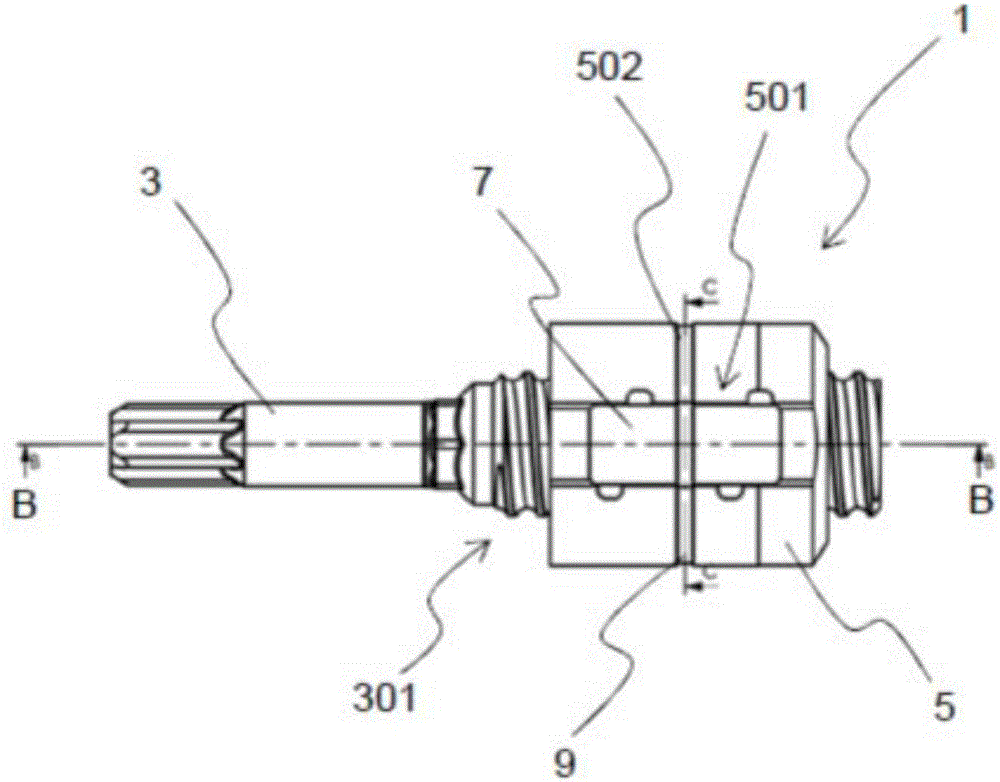

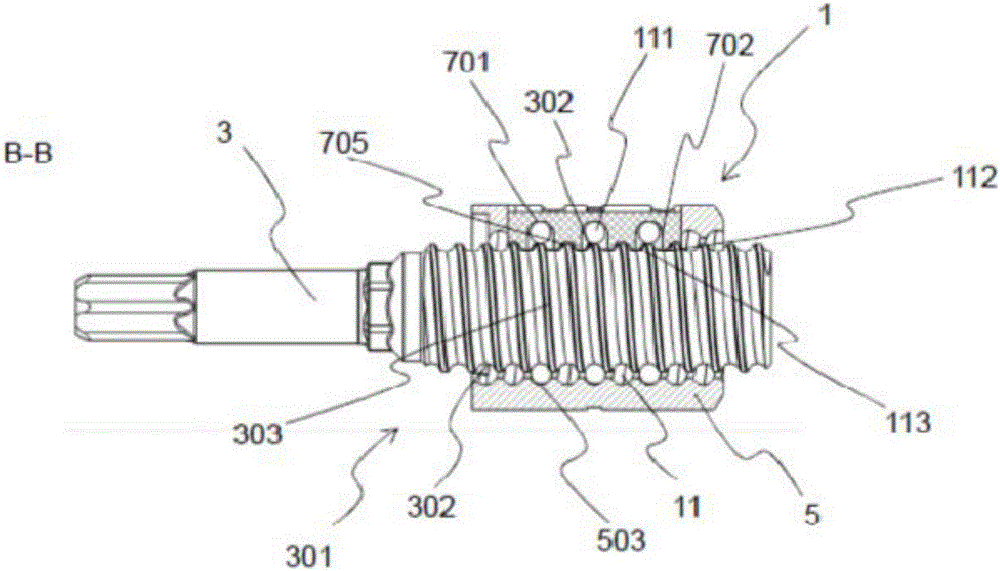

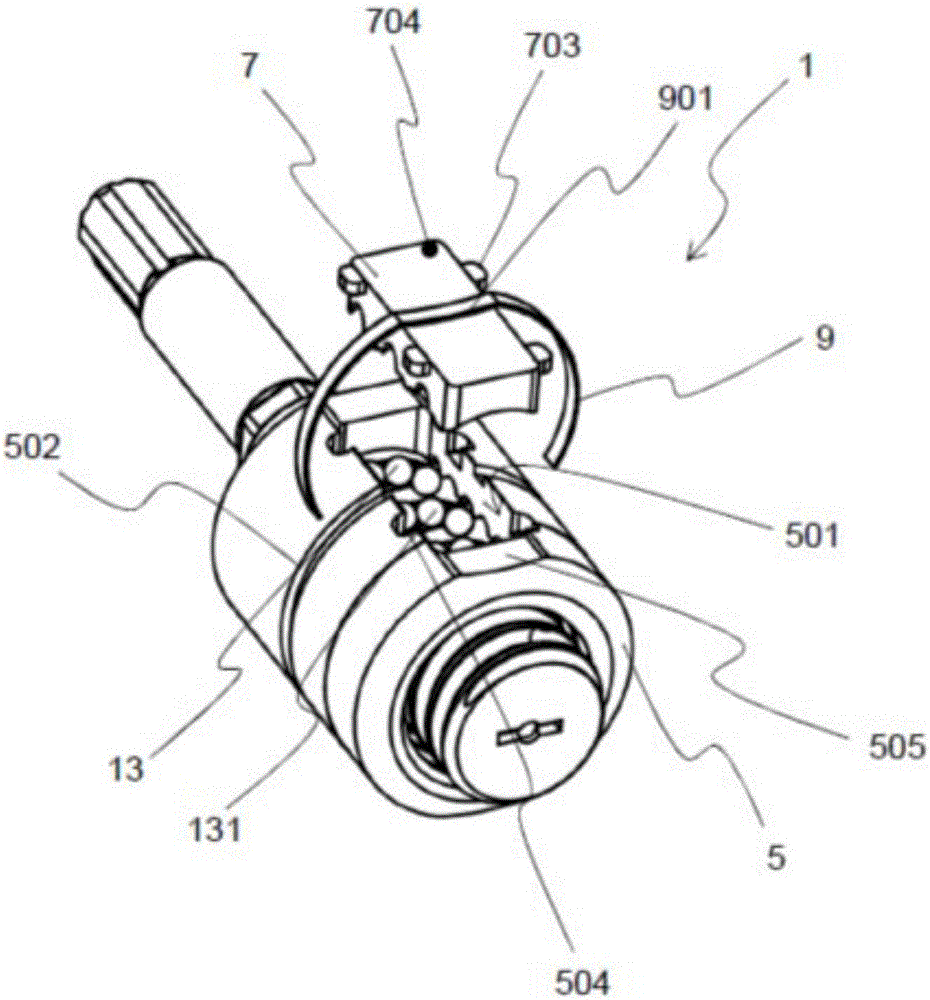

[0028] see Figure 1 to Figure 4 The shown ball screw 1 with ball reversing device can be used for electric parking brakes. The ball screw 1 comprises a screw shaft 3 and a ball nut 5 , wherein the ball nut 5 is arranged rotatably on a threaded section 301 of the screw shaft 3 . The screw shaft 3 and the ball nut 5 are coaxially arranged. In this embodiment, the ball screw 1 is integrated into the brake cylinder of the hydraulic service brake by utilizing common knowledge in the field, and other components of the electric parking brake are not shown in this figure, and the electric parking brake and the hydraulic pressure of the motor vehicle Service brake combination. Wherein the DC motor is connected with the lead screw shaft 3 through a force fit through a self-locking decele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com