Rock block friction coefficient measuring method and device based on fluid environment

A friction coefficient and measuring device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of not fully simulating the actual fluid environment of downhole rock blocks in oil and gas wells, lack of friction coefficient of rock blocks, etc., and achieve universal application performance, reduce deformation, and save rock samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

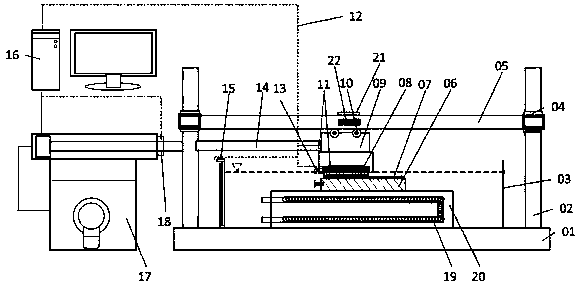

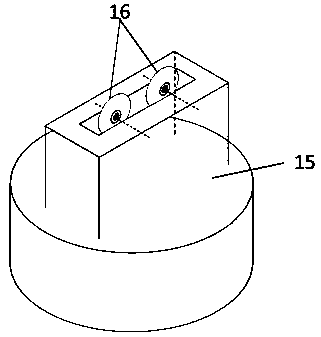

[0041] Such as figure 1 As shown, the present invention provides a fluid-environment-based measuring device for the coefficient of friction of rock blocks, including a sliding assembly, a bracket, a constant temperature liquid tank assembly, a control assembly, and a monitoring assembly.

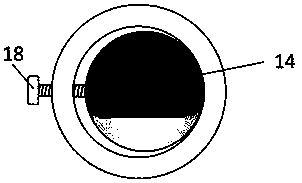

[0042] The sliding assembly includes a steel wheel set 10, a pressure transmission member 09, and an upper friction rock block fixing bolt 13. The steel wheel set 10 is composed of at least two steel wheels, which are used to connect with the steel rail 05 made of the same material as the steel wheel set 10. The pressure The transmission member 09 is used to equivalently transmit the vertical force of the rail 05 to the steel wheel to the upper surface of the upper friction rock block 08, and is used as the action point of the thrust rod 14 of the hydraulic device, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com