Rotary kiln fluidized roasting device and roasting process

A fluidized roasting and roasting process technology, applied in the field of metallurgy, can solve the problems of poor mineral reduction effect, low heat utilization rate, energy waste, etc., and achieve the effects of improving smelting effect, improving heat utilization rate, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

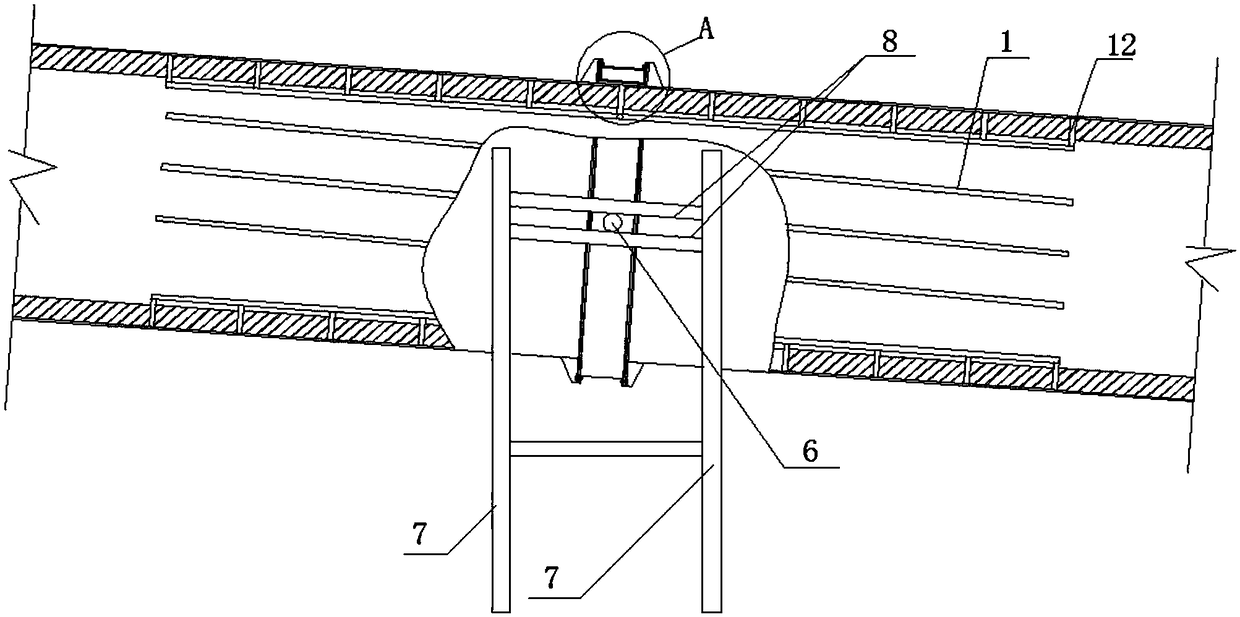

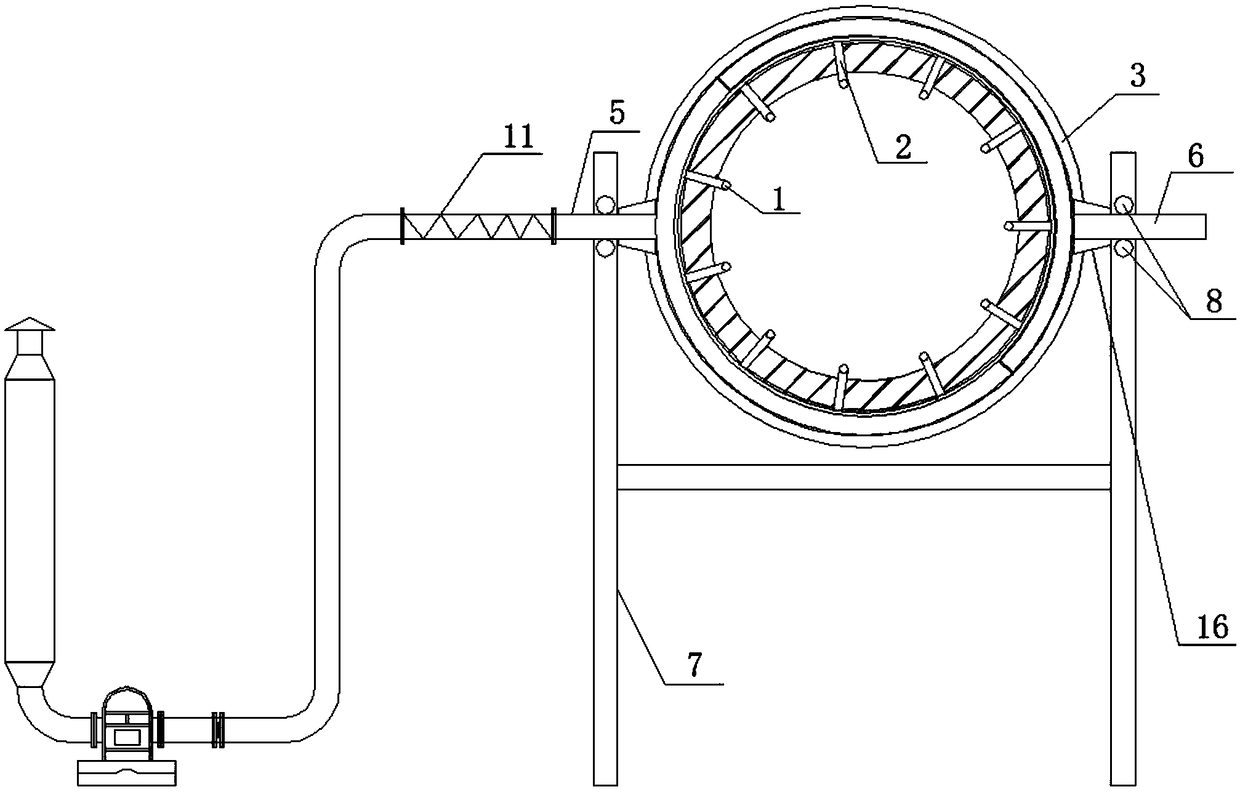

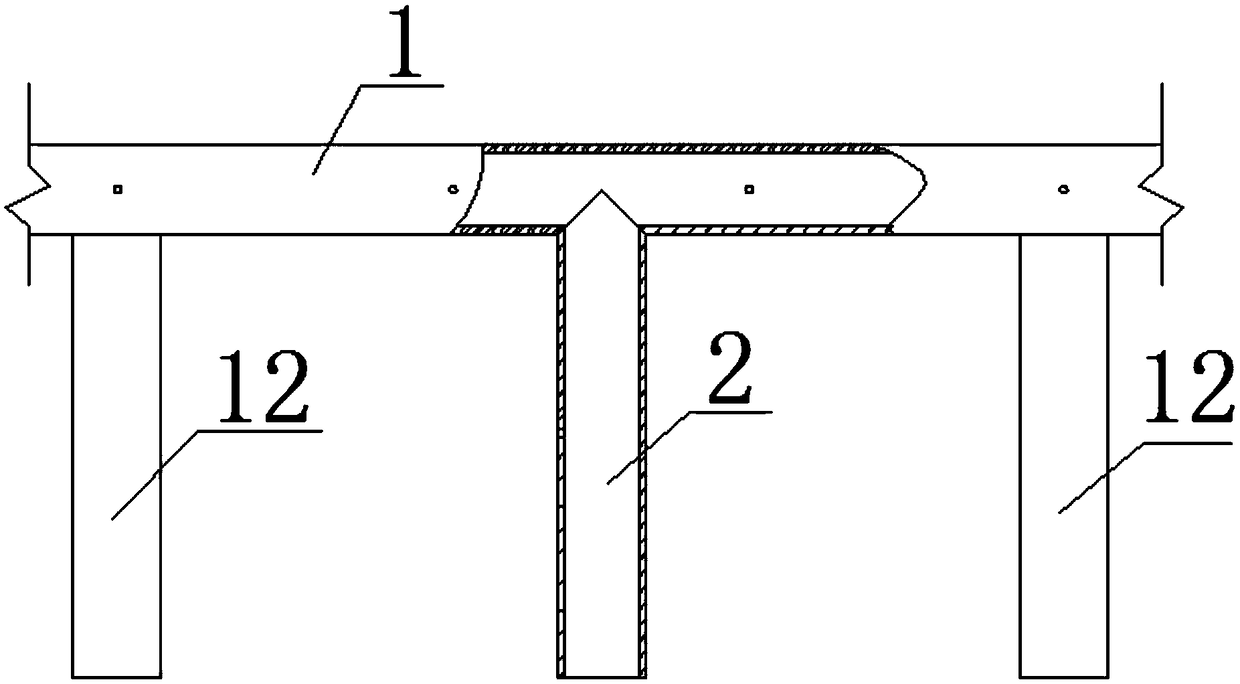

[0047] Rotary kiln fluidized roasting device has the advantages of high heat utilization rate, high volatile matter volatilization efficiency, good refining effect, low energy consumption and low smelting cost, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the following structure is specially set up: it includes a rotary kiln body, a total wind jacket and a blower connected in sequence, the total wind jacket is sleeved on the outer wall of the rotary kiln body, and the blower is arranged on the general wind jacket of the exterior. Wherein, the rotary kiln body is provided with a plurality of through holes with a diameter of 70mm along the circumferential direction in the middle of the middle temperature section, and the main air sleeve communicates with the interior of the rotary kiln body through the through holes.

[0048] Wherein, the total air jacket includes two air jacket retaining rings 3 and an air heating jacket clamped between the air jacket retain...

Embodiment 2

[0053] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as figure 2 As shown, the following arrangement structure is adopted in particular: a hose 11 communicates between the air blower and the air heating sleeve inlet pipe 5 . Because the rotary kiln will move to the kiln head due to its own gravity during operation, and will drive the air heating sleeve 4 to move at the same time, which makes the air heating sleeve inlet pipe 5 welded on the air heating sleeve 4 and the blower The position between them is constantly changing, and the hose 11 can offset the relative displacement between the air blower and the air heating sleeve inlet pipe 5, and can improve the connection reliability between the air blower and the air heating sleeve 4.

Embodiment 3

[0055] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the following arrangement structure is adopted in particular: an air injection device is arranged inside the rotary kiln body, and the air injection device includes a plurality of air injection main pipes 1 laid obliquely along the inner wall of the rotary kiln, and the middle part of the air injection main pipe 1 The air inlet pipe 2 is fixed to the inner wall of the rotary kiln body, and the air inlet pipe 2 and the air heating sleeve 4 communicate with the gap formed between the rotary kiln body; A plurality of jet holes with a diameter of 5mm are provided, and the specific number of jet holes is selected according to actual usage conditions. The gas is sprayed into the interior of the rotary kiln body through the gas injection holes, and the pressure of the gas injected in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com