Stirring device for organic waste treatment

An organic waste and stirring device technology, which is applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of environmental groundwater pollution, influence on fermentation effect, and low efficiency of biodegradable organic waste treatment, and achieve uniformity The effect of rapid heating of materials and sufficient contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

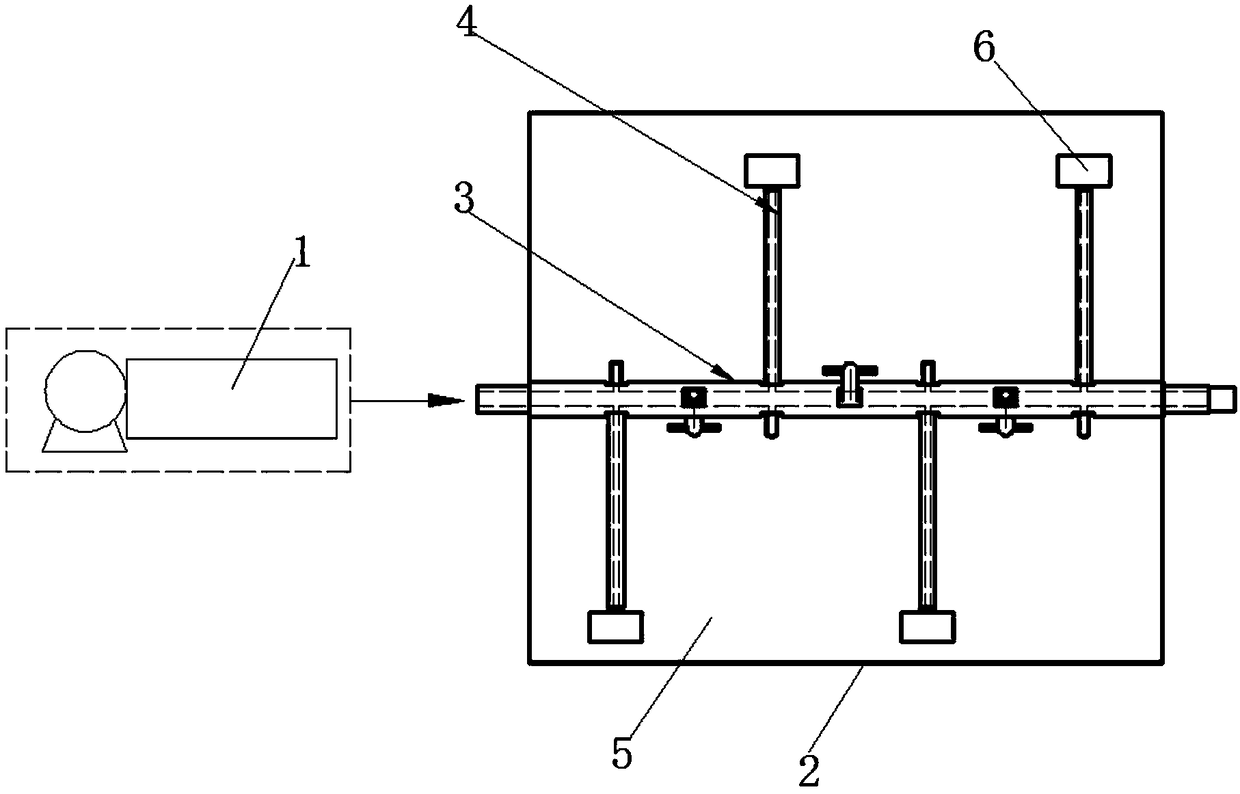

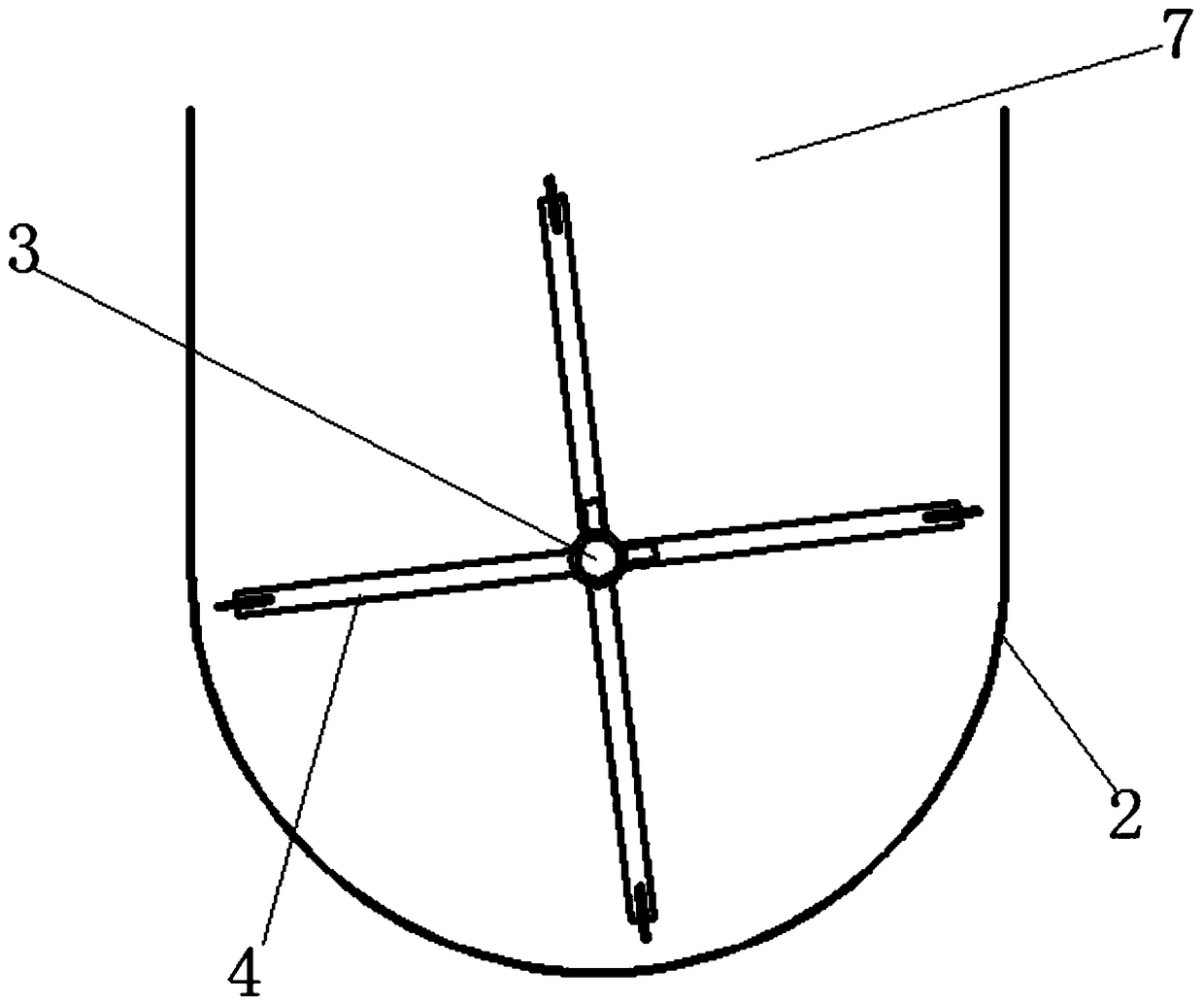

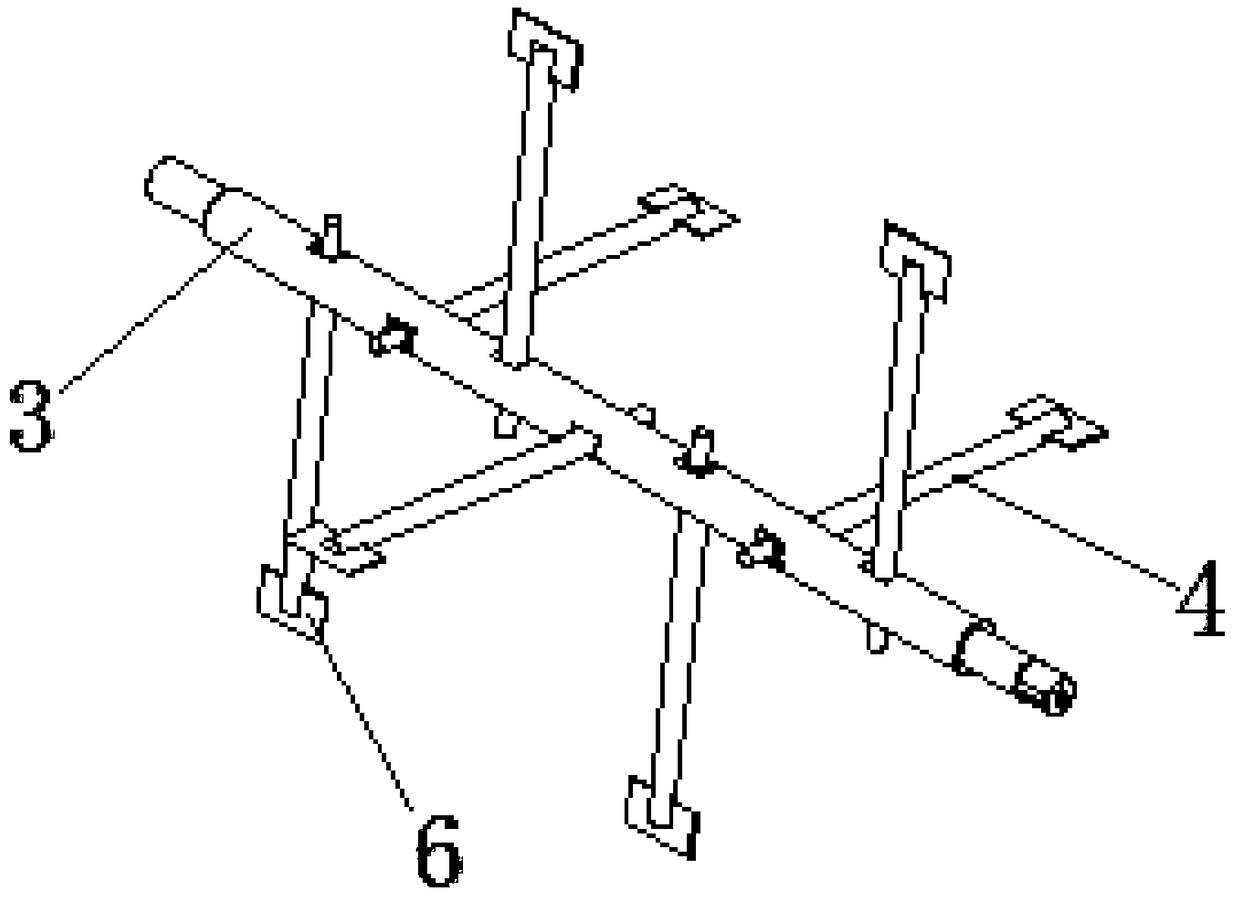

[0020] Such as figure 1 and combine figure 2 and image 3 As shown, a stirring device for organic waste treatment includes a stirring body, a stirring spindle 3, a hot air blower 1 and several stirring rods 4. The stirring body includes a housing 2, and a biochemical Compartment 5, the stirring spindle 3 is connected to the center line of the biochemical chamber 5, the two ends of the stirring spindle 3 are rotatably connected to the housing 2, and each stirring rod 4 is respectively spaced and fixed on the circumference of the stirring spindle 3 On the part, a first cavity is formed in the stirring main shaft 3, a second cavity is formed in the stirring lever, the hot air blower 1 is connected with the stirring main shaft 3 through an air duct a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com