Control method for air-fuel ratio of pusher heat accumulating type heating furnace

A control method and heat storage technology, which is applied in the direction of furnace control devices, lighting and heating equipment, furnaces, etc., can solve the problems of uncontrollable air-fuel ratio, achieve the effect of reducing replacement frequency, reducing energy consumption, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

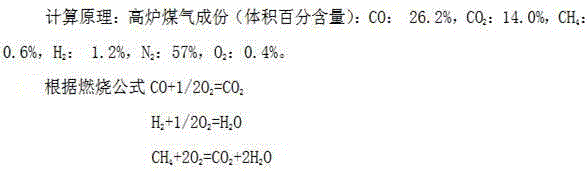

Method used

Image

Examples

Embodiment 1

[0018] Example 1: The air-fuel ratio of the first and second addition stages is 0.8, the air-fuel ratio of the third addition stage is 0.75, and the air-fuel ratio of the soaking stage is 0.7. This embodiment has the best effect.

Embodiment 2

[0019] Example 2: The air-fuel ratio of the first and second-addition sections is 0.85, the air-fuel ratio of the three-addition section is 0.80, and the soaking section is 0.75.

Embodiment 3

[0020] Example 3: The air-fuel ratio of the first and second-increasing section is 0.75, the air-fuel ratio of the three-increasing section is 0.70, and the air-fuel ratio of the soaking section is 0.70.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com