High-efficiency low-resistance heat tube afterheat recycling device

A waste heat recovery device and heat pipe technology, applied in the direction of heat exchangers, heat exchanger types, indirect heat exchangers, etc., can solve the problems of multi-site maintenance labor, discontinuous water spray, and easy blockage of spray holes, etc., to achieve heat recovery The effect is good, the effect of improving the condensation heat transfer efficiency and prolonging the heat release time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

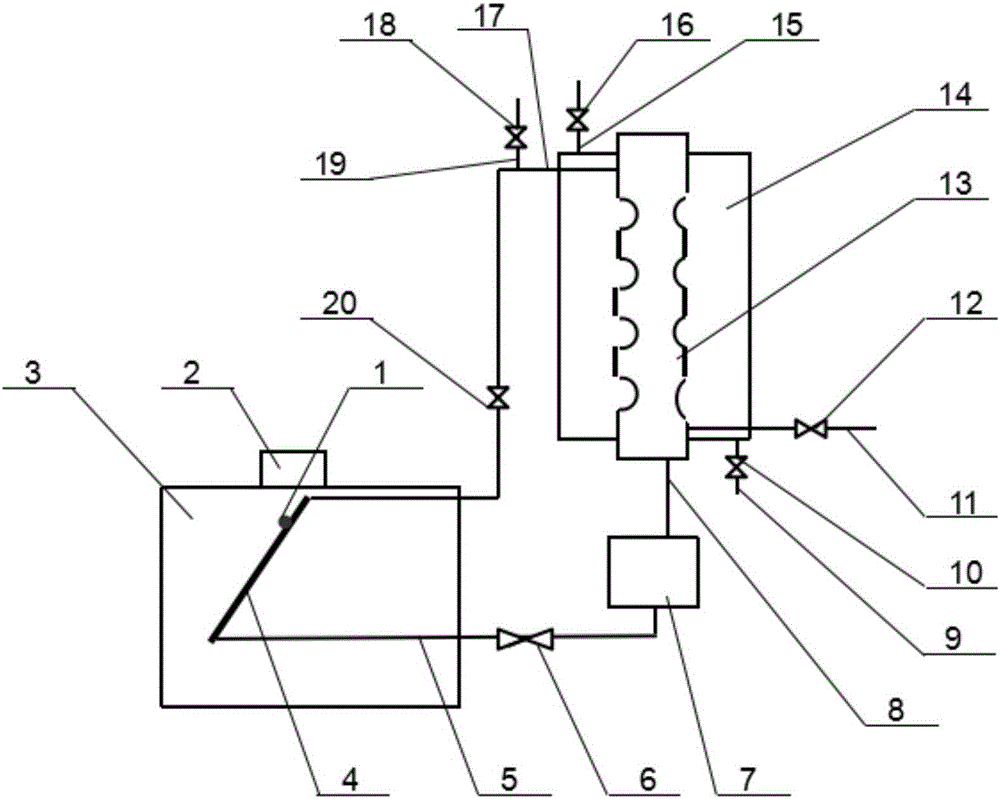

[0019] The present invention is described in further detail below in conjunction with accompanying drawing:

[0020] see figure 1 , a high-efficiency and low-resistance heat pipe waste heat recovery device of the present invention is composed of an evaporation section and a condensation section, a liquid storage chamber 7 is arranged between the evaporation section and the condensation section; the evaporation section includes a carbonization chamber 3, and the top of the carbonization chamber 3 is provided with a drop The coke mouth 2; the film evaporation tube 4 is arranged in the carbonization chamber 3, and the semi-coke 1 enters the carbonization chamber 3 from the coke drop port 2, and falls into the upper surface of the film evaporation tube 4; the condensation section includes a corrugated condenser tube 13, corrugated The upper end of the condensation pipe 13 is connected to the upper end of the film evaporation pipe 4 through the steam pipe 17, the lower end of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com