Method and device for improving concentration speed of diameter-variable concentration cup

A technology of speed and sub-device, which is applied in the field of increasing the concentration rate of variable-diameter concentration cups, can solve the problems of speeding up the concentration rate, increasing gas consumption, and increasing the cost of the experiment, so as to reduce the exposed area, save the concentration time, and save the cost of the experiment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

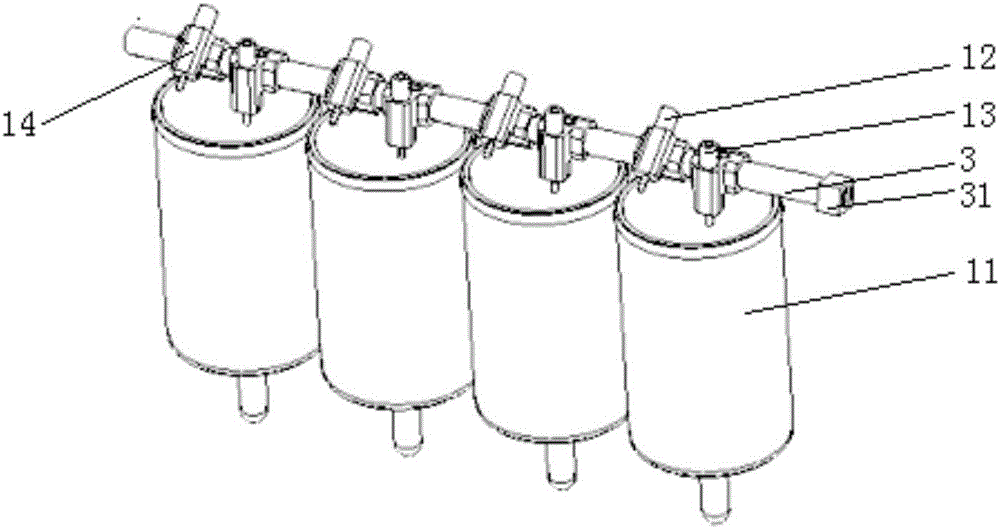

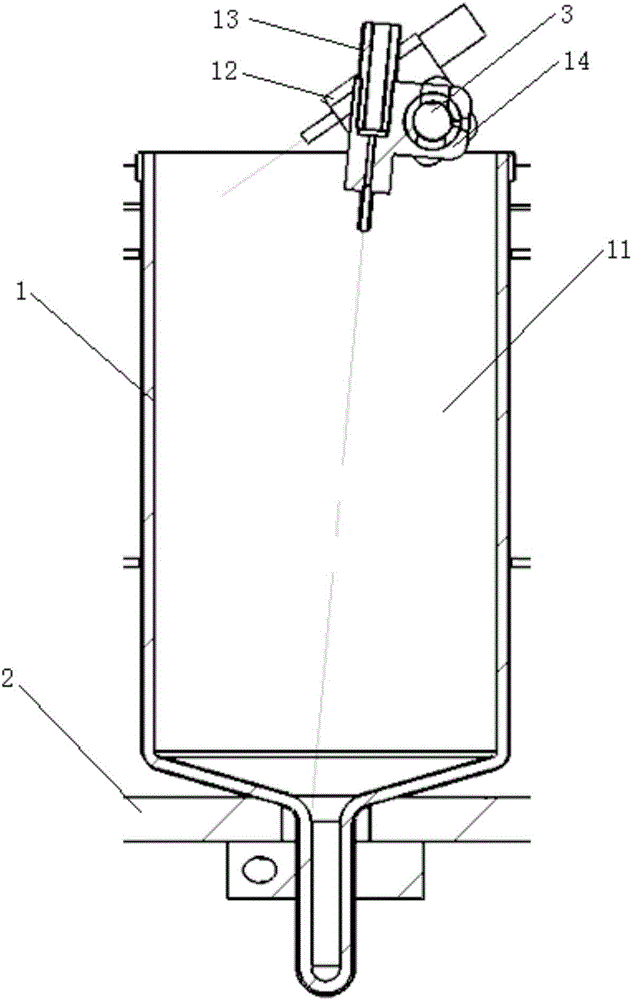

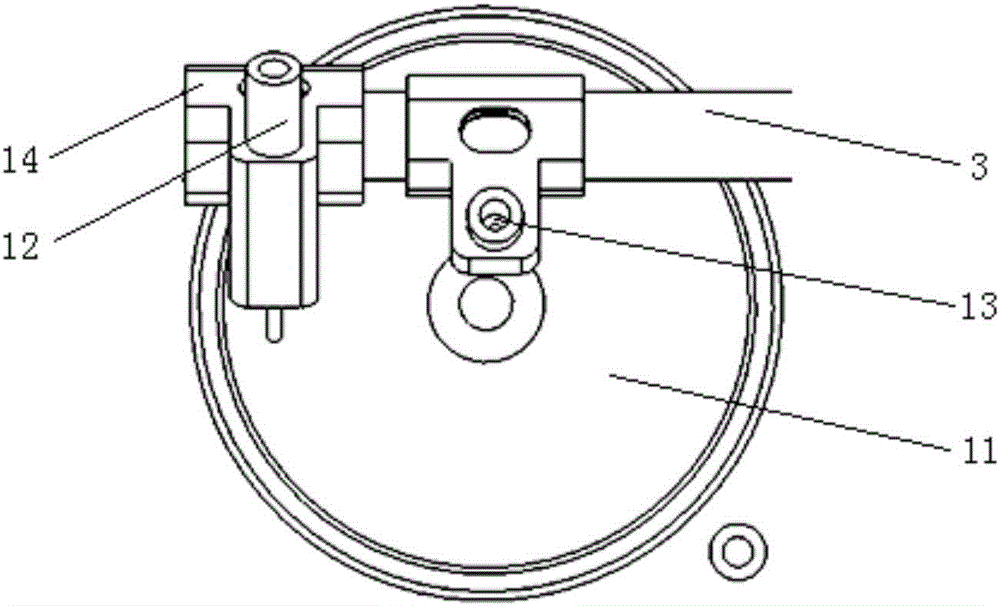

[0017] Such as Figure 1~3 As shown, the device for improving the concentration rate of the variable-diameter concentration cup of the present invention includes several concentration sub-devices 1, a support frame 2 and an air pipeline 3, and each concentration sub-device 1 includes a large-diameter upper part and a small-diameter lower part. Reduced-diameter concentrated cup 11, two blowing needle connectors 12, a first blowing needle 13 and a second blowing needle 14;

[0018] The bottom of the support frame 2 is horizontally provided with the same number of through holes as the variable diameter concentration cups 11. The support frame 2 can be in any form, and will not be repeated here. The lower small diameter of each variable diameter concentration cup 11 passes through the through holes. It is fixedly connected with the support frame 2, and the upper part of each variable-diameter concentration cup 11 is fixedly connected to the support frame 2, and the top of all the ...

Embodiment 2

[0025] The structure of this embodiment is basically the same as that of Embodiment 1, and the difference is that in this embodiment, the two blowing needle connectors 12, the first blowing needle 13 and the second blowing needle 14 in each concentration sub-device 1 of Embodiment 1 are Replaced with a movable blowing needle connecting frame 12 on the air pipeline 3 and a blowing needle 13 movably connected on the blowing needle connecting frame 12, when the solvent to be concentrated is in the large diameter of the variable-diameter concentration cup 11, the blowing needle The connecting frame 12 is fixedly arranged on the top of the variable-diameter concentration cup 11, and the air outlet direction of the blowing needle 13 is at an angle of 45° to any tangent direction of the inner wall cross section at 1-5 cm from the variable-diameter concentration cup 11 cup mouth. When being in the small diameter of the reduced-diameter concentration cup 11 , the blowing direction of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com