In-situ high temperature micromechanics testing device in scanning electron microscope

An electron microscope and testing device technology, applied in measuring devices, using stable tension/pressure to test the strength of materials, scientific instruments, etc. It can solve the problems of large design volume and high weight, and achieve the effect of compact structure and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

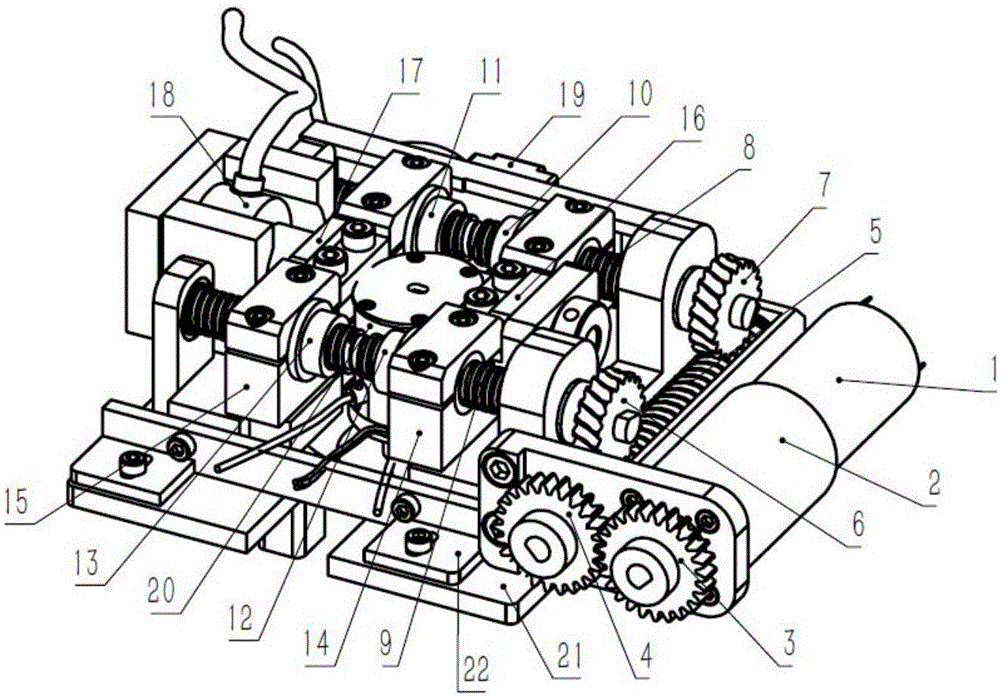

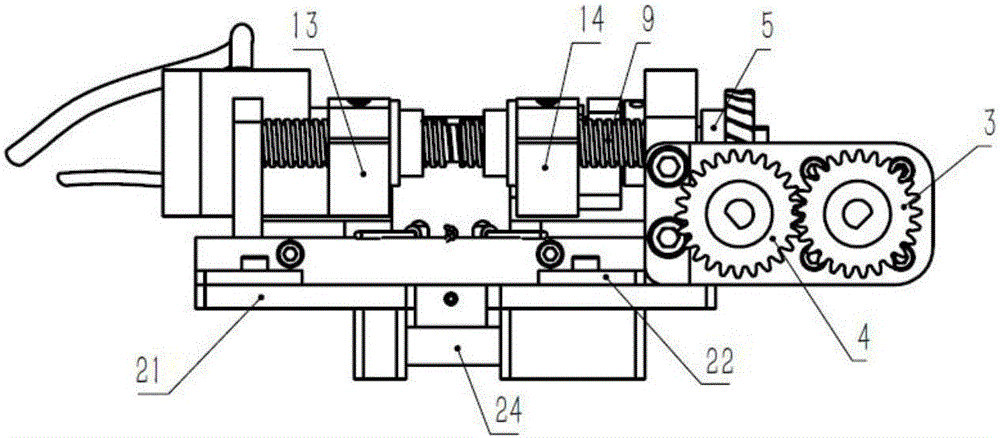

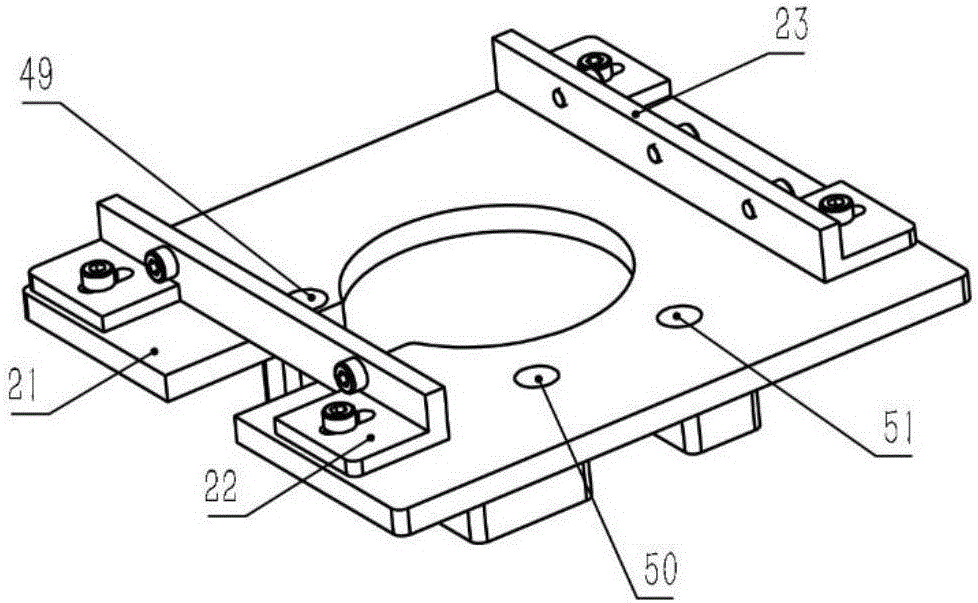

[0039] like Figures 1 to 11 , the present embodiment provides an in-situ high-temperature micromechanical testing device in a scanning electron microscope, including a control system 46, a tensile testing device, a heating device 20 and a fixing device. The tensile testing device is provided with an accommodating space, and the heating device 20 is arranged on In the accommodating space, the heating device 20 is used to provide a high temperature environment for the sample 30, and the tensile testing device applies a load to the sample 30, so that the sample 30 is tested under high temperature load; the tensile testing device and the heating device 20 The bottom ends are all connected with the fixture, and the bottom of the fixture is fixedly connected with the sample support frame 24 of the scanning electron microscope, that is, the whole micromechanical testing device is placed in the scanning electron microscope; the tensile testing device, the heating device 20 and the fix...

Embodiment 2

[0051] The basic structure of this embodiment is the same as that of Embodiment 1. The difference is that the in-situ high-temperature micromechanics testing device in the scanning electron microscope in this embodiment is a tilting in-situ tensile testing device, and the tilting original In the tensile testing device, the clamps arranged at the middle position on the top of the first sample clamp support frame 14 and the middle position on the top of the second sample clamp support frame 15 are respectively the first inclined clamp 47 and the second inclined clamp 48; The device is an inclined fixing device, and the inclined fixing device includes an inclined fixing seat 52, an inclined plate 53 and a supporting rib plate, and the inclined fixing seat 52 and the inclined plate 53 are arranged at an angle, and the inclined fixing seat 52 is fixedly connected with the sample support frame 24 of the scanning electron microscope , one end of the inclined fixing seat 52 is fixedly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com