Assembly sequence planning method of complex assembly on the basis of assembly matrix

A technology for assembly sequence planning and assembly, which is applied in special data processing applications, instruments, electrical and digital data processing, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

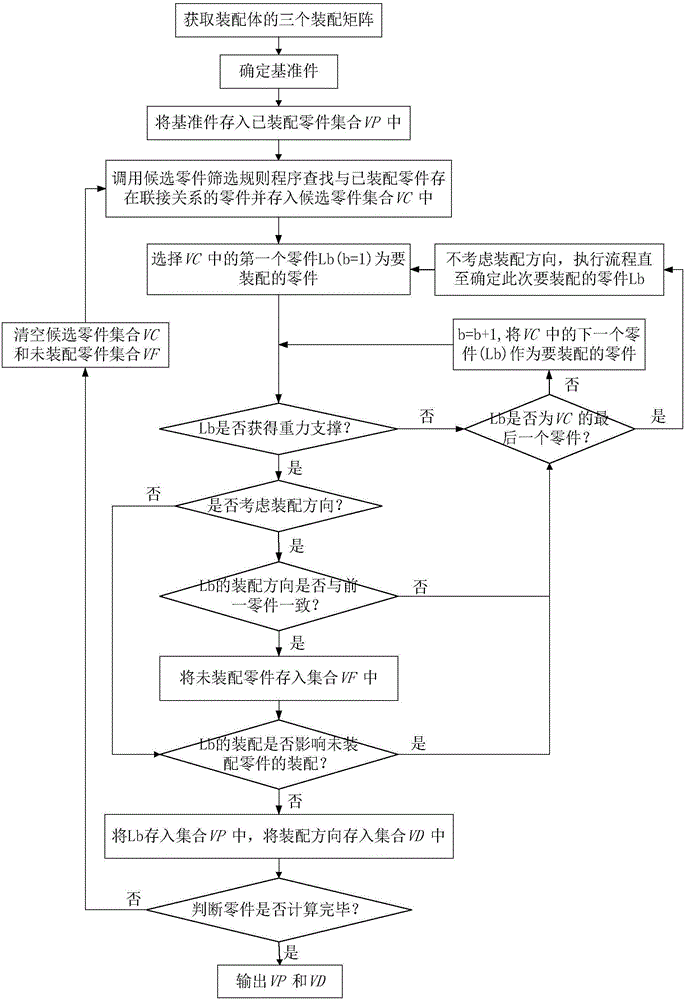

Method used

Image

Examples

Embodiment 1

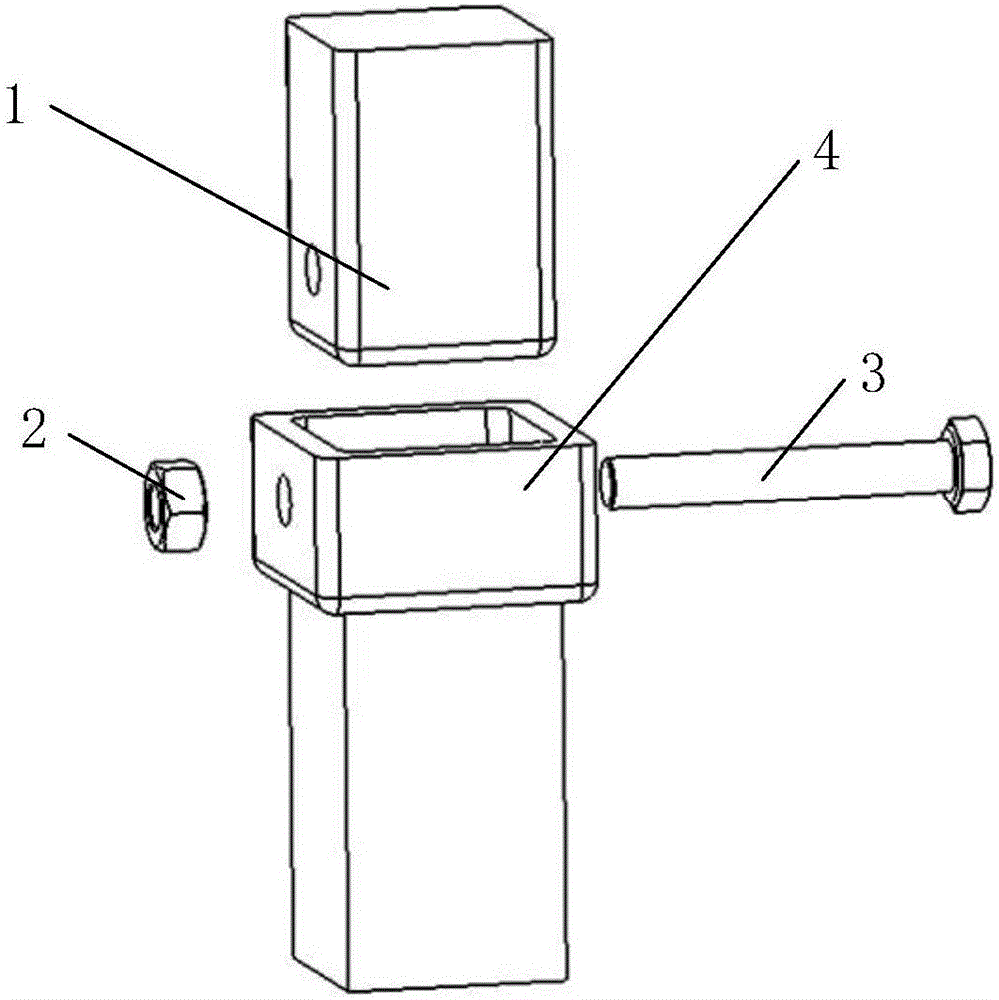

[0073] Such as figure 2 As shown, through the method of generating the assembly matrix, listing figure 2 The three assembly matrices of the assembly composed of 4 parts: assembly connection matrix C, assembly support matrix G, and assembly interference integration matrix IN are as follows:

[0074] C = 0 0 1 1 0 0 1 1 1 1 0 1 1 1 1 0 ; G = 0 0 1 1 0 0 1 0 1 0 0 0 0 0 0 0 ; IN = 0 0 7 6 2 0 7 2 5 5 0 5 7 0 7 0 ,

[0075] Then according to the determination of the reference part, the sum of the rows of the fourth row of the assembly support matrix G is zero, then the part 4 can be determined as the reference part, and 4 is stored in the set VP storing the assembled parts.

[0076] Use candidate parts screening rules to find parts that have ...

Embodiment 2

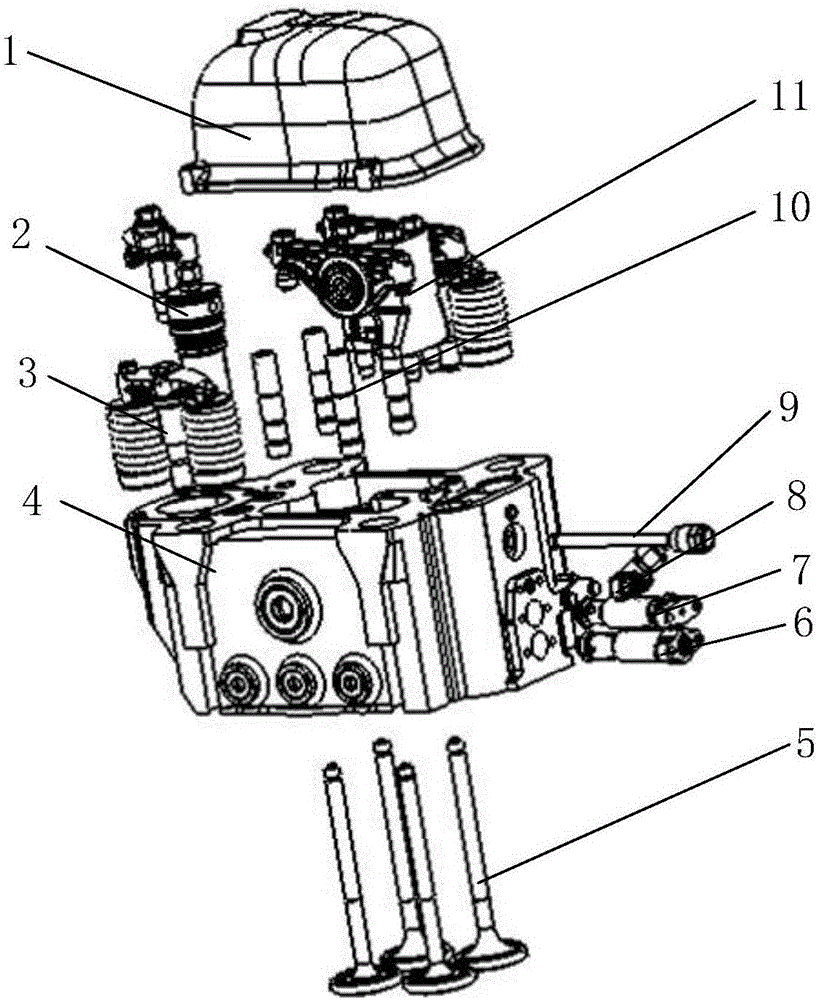

[0084] See image 3 , Through the method of generating assembly matrix, list image 3 The assembly connection matrix C, assembly support matrix G, and assembly interference integration matrix IN of the assembly composed of 11 parts are as follows:

[0085] C=0001000000000010000100000110000111110111111100110000001000100000000001000000000010000000010100000000011000000000111000000;G=0001000000000010000000000100000000000000000000100000000000100000000001000000000010000000 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 ; IN = 0 6 6 0 0 0 0 0 0 6 0 7 0 6 6 2 0 0 0 3 0 0 7 6 0 6 6 0 0 0 0 3 6 1 7 7 0 6 3 3 3 3 7 7 7 2 7 7 0 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com