Radioactive resin treatment system and method

A treatment system and treatment method technology, which is applied in the field of low and medium radioactive waste treatment, can solve the problems of high airtightness of outer packaging containers and high requirements for disposal environment, large waste package volume, and many acid gases, so as to meet the requirements of waste packaging, Effect of reducing waste disposal cost and reducing waste package volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the objectives, technical solutions and beneficial technical effects of the present invention clearer, the present invention will be further described in detail below in conjunction with examples. It should be understood that the examples described in this specification are only for explaining the present invention, not for limiting the present invention, and the formulas and ratios of the examples can be selected according to local conditions without substantial influence on the results.

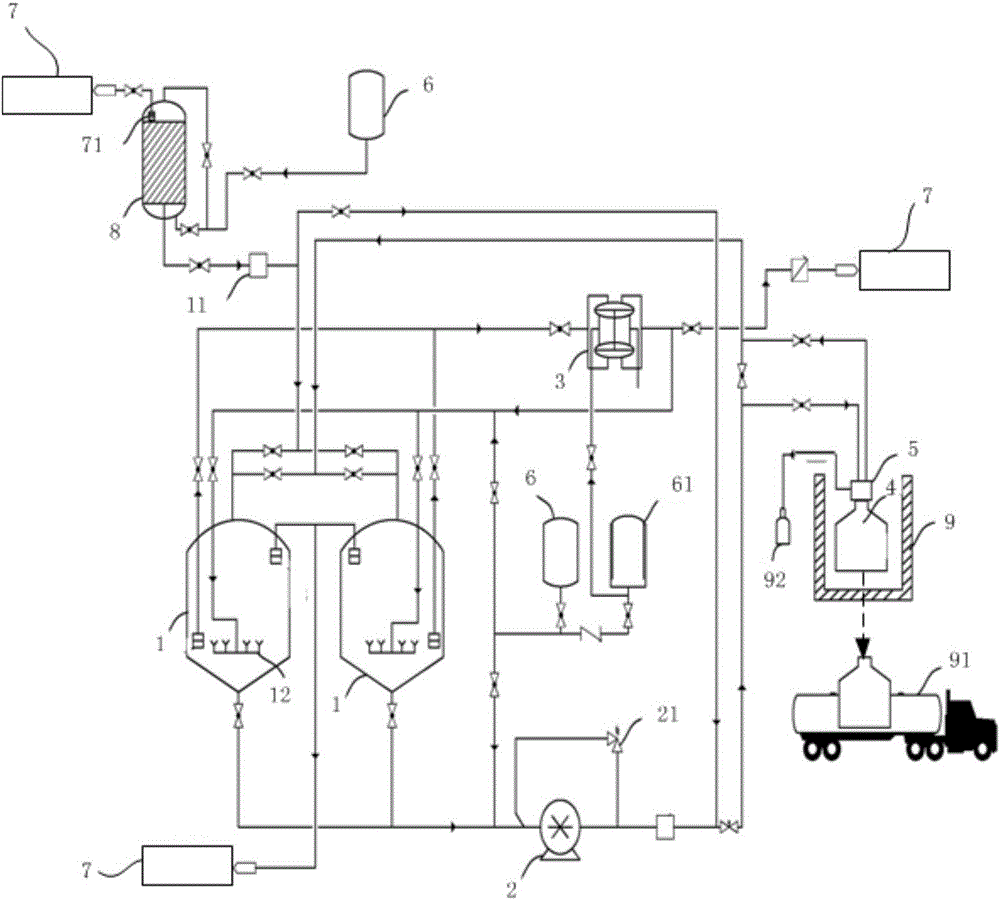

[0035] see figure 1 , the processing system of radioactive resin of the present invention comprises:

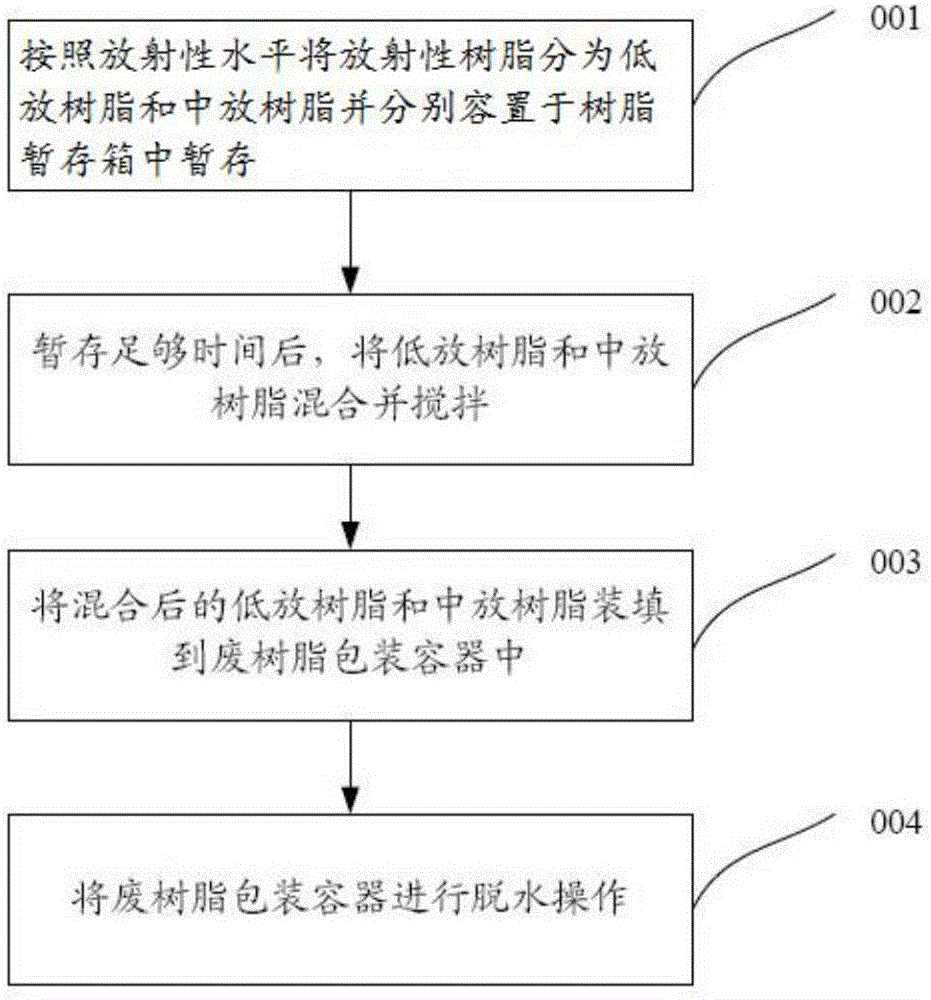

[0036] Two resin temporary storage boxes 1 are used to temporarily store the low-release resin and the medium-release resin flushed and discharged therein;

[0037] The conveying device 2 is used to mix the temporarily stored low-level resin and medium-level resin; it is also used to transport the low-level resin and medium-level resin to the waste resin packaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com