Vehicle lithium battery working condition management system and control method thereof

A management system and lithium battery technology, applied in battery/fuel cell control devices, vehicle components, vehicle energy storage, etc., can solve problems such as restricting the application and development of lithium batteries, large differences in use environments, and large vehicle energy consumption, etc. To achieve the effect of improving the safety of use, reliable cooling, and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

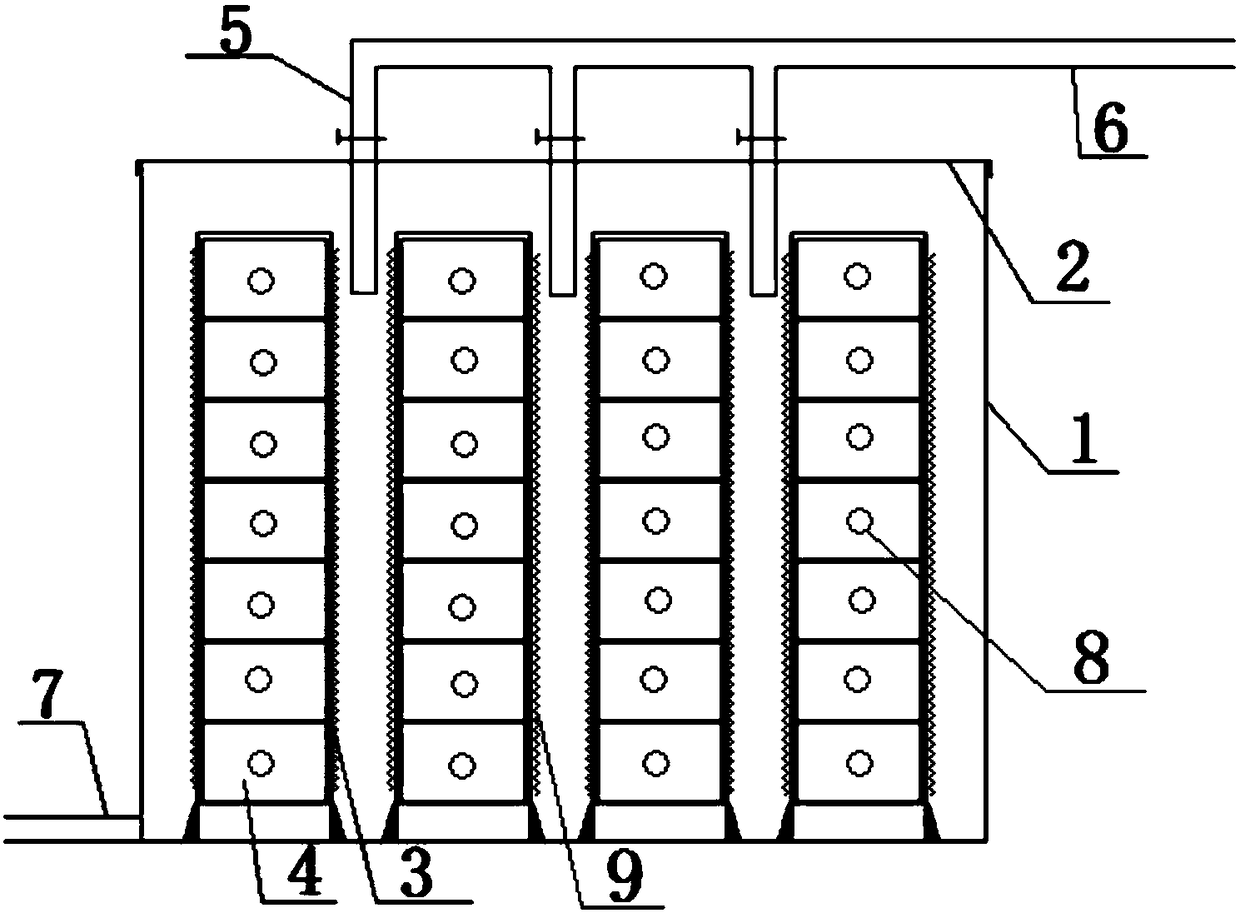

[0032] The vehicle lithium battery working condition management system is that the lithium battery is placed in the liquid, and the lithium battery is cooled by liquid circulation and kept at a constant temperature, such as figure 1 As shown, the system is equipped with a battery box 1 filled with a heat dissipation medium. The medium is an oily medium with good heat conduction. There are multiple hollow columnar placement cavities 3 vertically in the battery box 1. The placement cavities 3 are columnar with a quadrilateral bottom surface. structure, the interior is hollow and sealed, and the lithium battery cells 4 are stacked one by one in the placement cavity 3, and the placement cavity 3 is made of a material with good thermal conductivity.

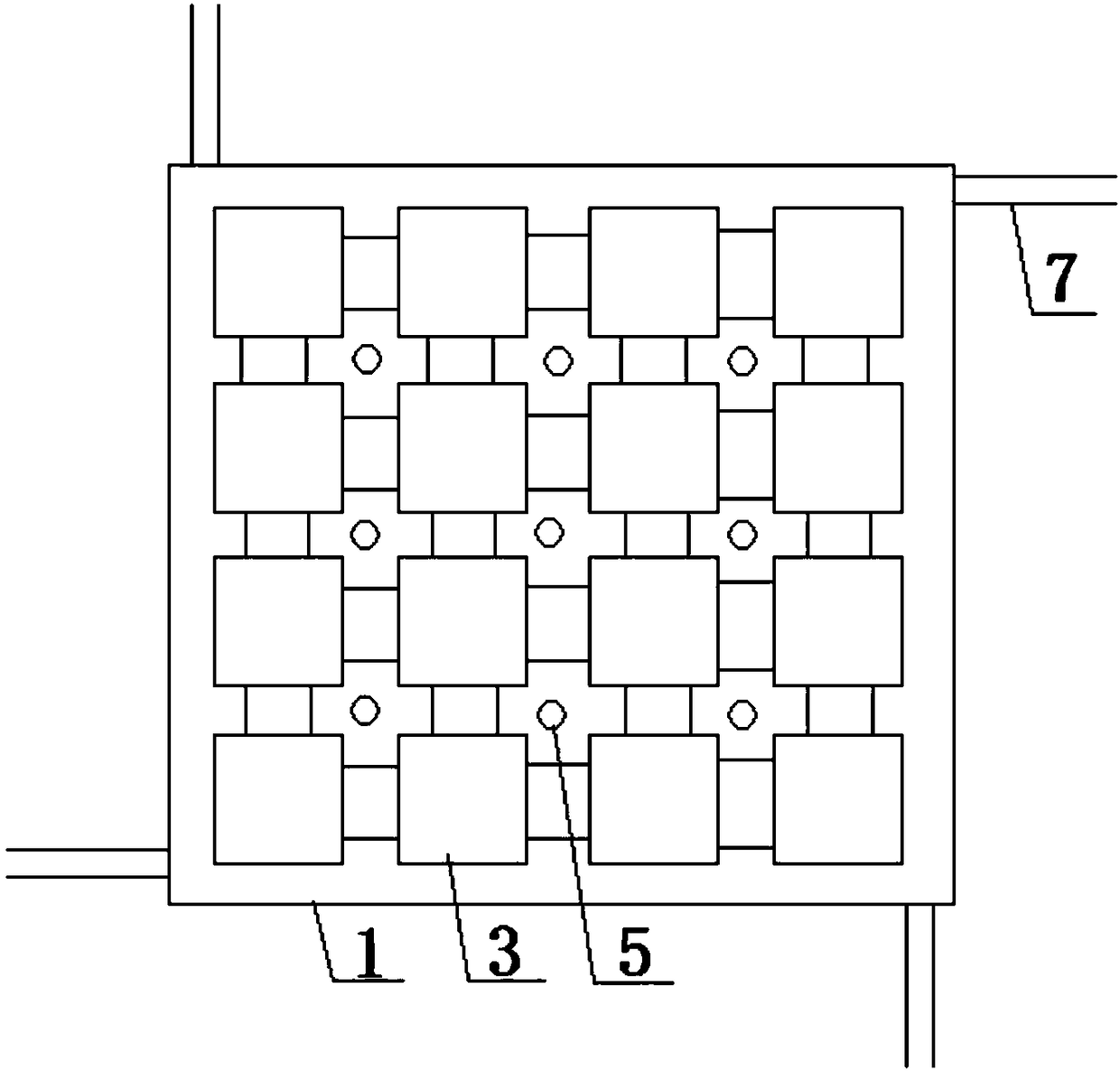

[0033] In order to improve the utilization rate of space, the placement chamber 3 is fixed on the bottom of the battery box 1 in a row-column matrix structure. The row-column matrix structure means that the placement chamber 3 is horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com