Rotary cultivator with function of removing soil heavy metal

A heavy metal and rotary tiller technology is applied in the field of rotary tillers, which can solve the problems of not having the ability to spread and adsorb heavy metal particles in soil and the single operation function of the rotary tiller, and achieve the effects of saving manpower, optimizing operation methods and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

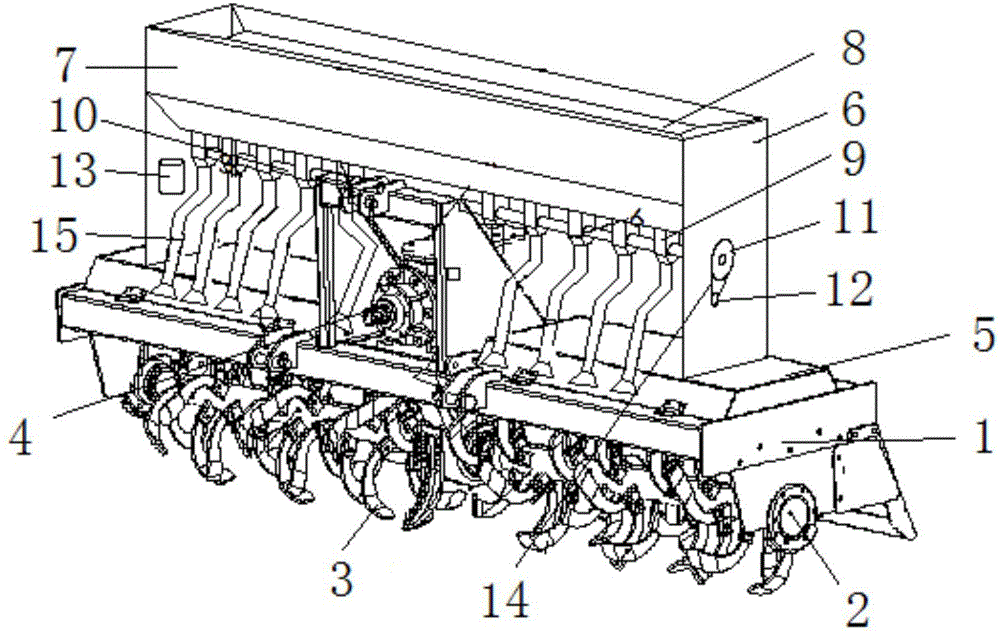

[0018] See attached picture:

[0019] A rotary tiller with the function of removing heavy metals from the soil, including a frame 1, a cutter shaft 2 is installed on the lower side of the frame 1, a coulter 3 is installed on the cutter shaft 2, a gear box 4 is installed in the middle of the upper end surface of the frame 1, and a gear The box 4 drives the cutter shaft 2 to rotate through multiple sets of gear pairs that mesh with each other. A cover plate 5 is installed on the frame outside the gear box 4. The upper end of the cover plate 5 is provided with support plates 6 that are placed on both sides of the gear box. A fertilizer box 7 is installed on the upper end of the plate 6, and the inside of the fertilizer box 7 is provided with a heavy metal particle removal box 8, and a plurality of fertilizer dischargers 9 are installed at intervals on the bottom plate of the fertilizer box 7, and the plurality of fertilizer dischargers 9 are driven by two left and right fertilizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com