Pipe discharging, threading and assembling operation table

A technology for consoles and threading, applied to workbenches, manufacturing tools, etc., can solve the problems of bulky size, increased construction difficulty, difficulty in transportation and carrying, etc., and achieve the effect of improving work efficiency and reducing work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

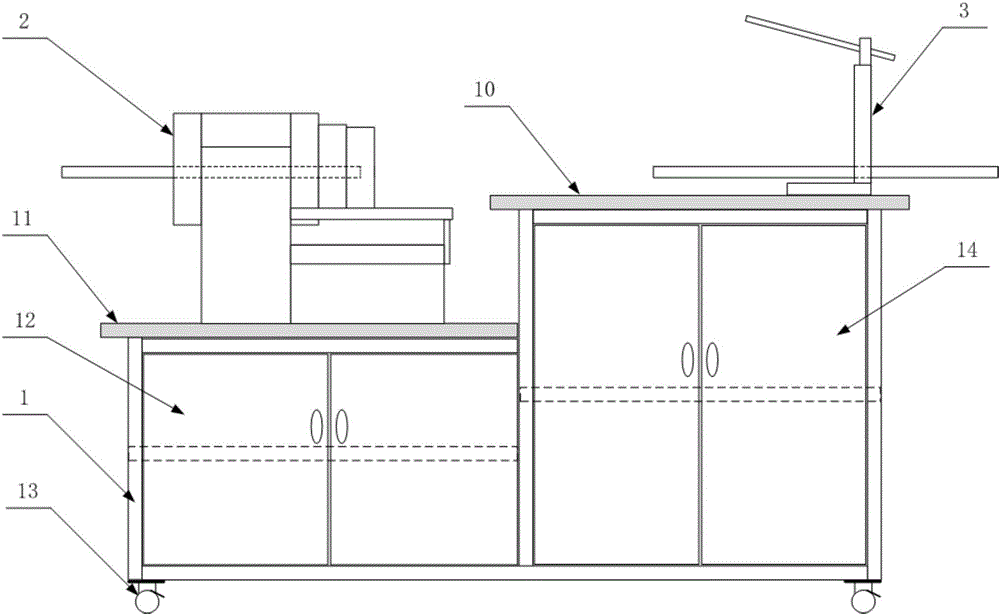

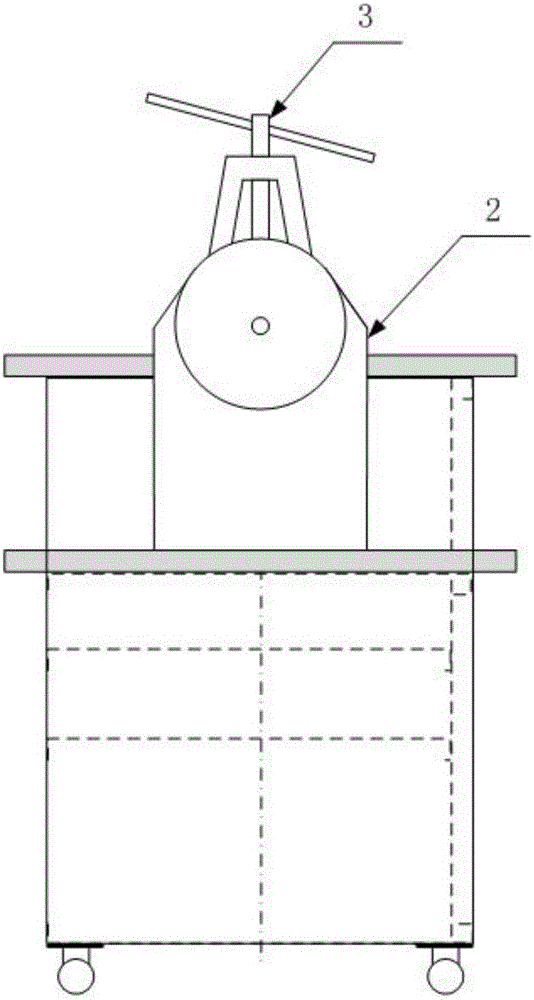

[0020] Such as figure 1 , 2 As shown, a pipe blanking, threading, and assembly operation platform includes a cabinet body 1, a threading machine 2 and a bench vise 3.

[0021] The threading table is 1350mm long, 500mm wide and 750mm high, suitable for cutting, threading and assembly of DN15-DN50 steel pipes and cutting and assembly of DN20-DN110PVC pipes.

[0022] The cabinet body 1 is an all-steel plastic-sprayed cabinet body, which is designed according to ergonomic principles and adopts a stepped structure. Bench vise 3 is installed on high table top 10, double as operating table, below is two layers of lockers (comprising low locker 12 and high locker 14), and 6 mobile universal runners 13 are installed at the bottom.

[0023] The low locker 12 is designed as a lockable double-opening cabinet door, which is suitable for placing larger toolboxes and com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com