A container ship capable of loading and unloading cargo

A container ship and container technology, applied in the direction of cargo handling equipment, hull, ship construction, etc., can solve the problems of high investment cost of container ship terminals, restrictions on the development of container transportation industry, single container transportation routes, etc., to achieve stable connection and convenient transportation , the effect of improving transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

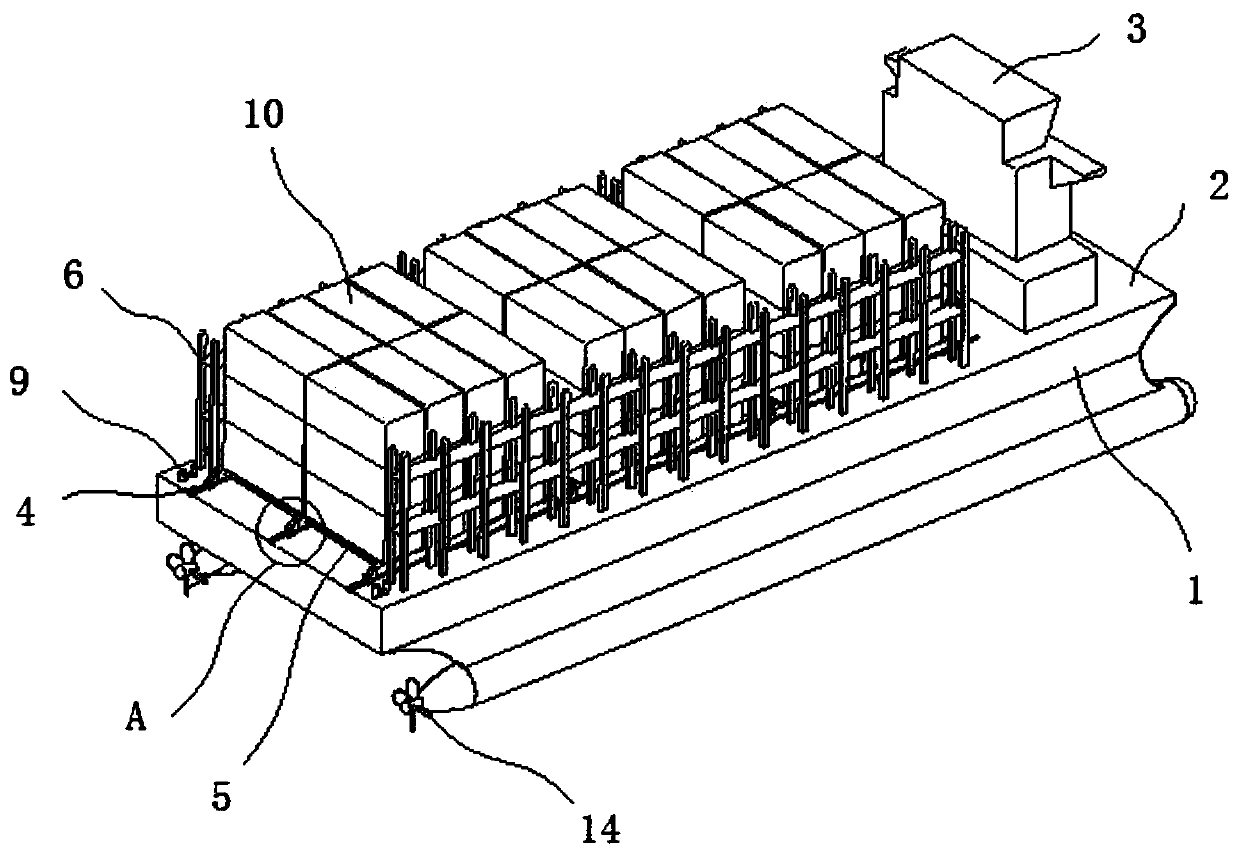

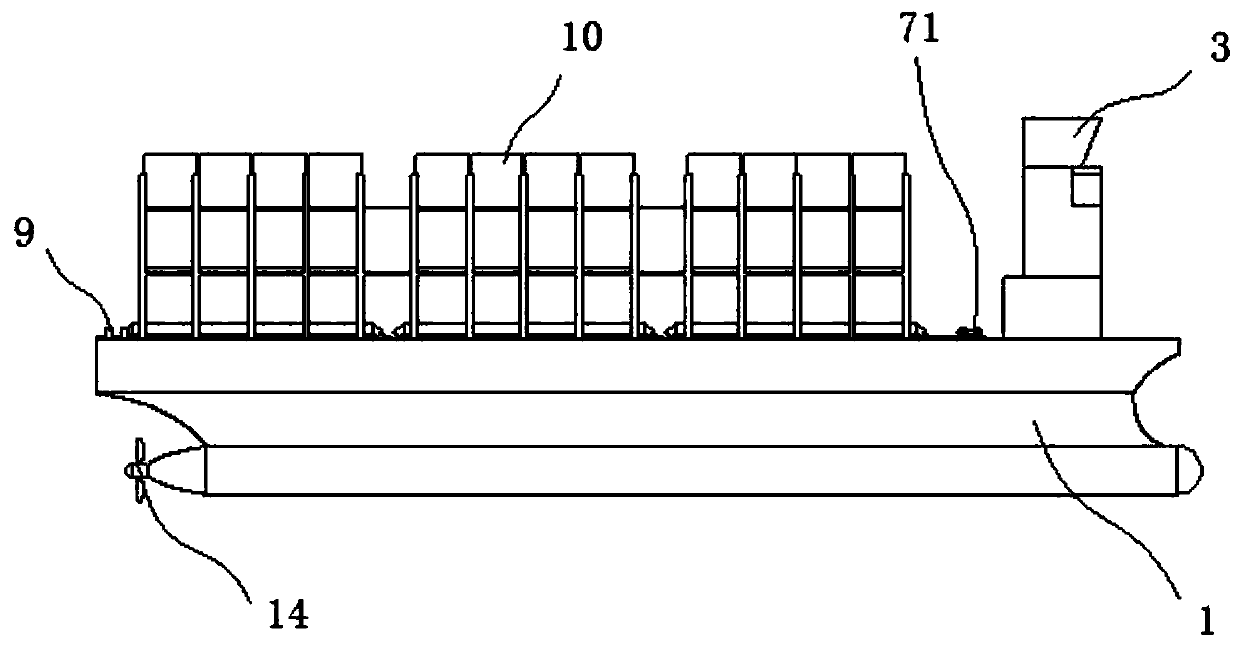

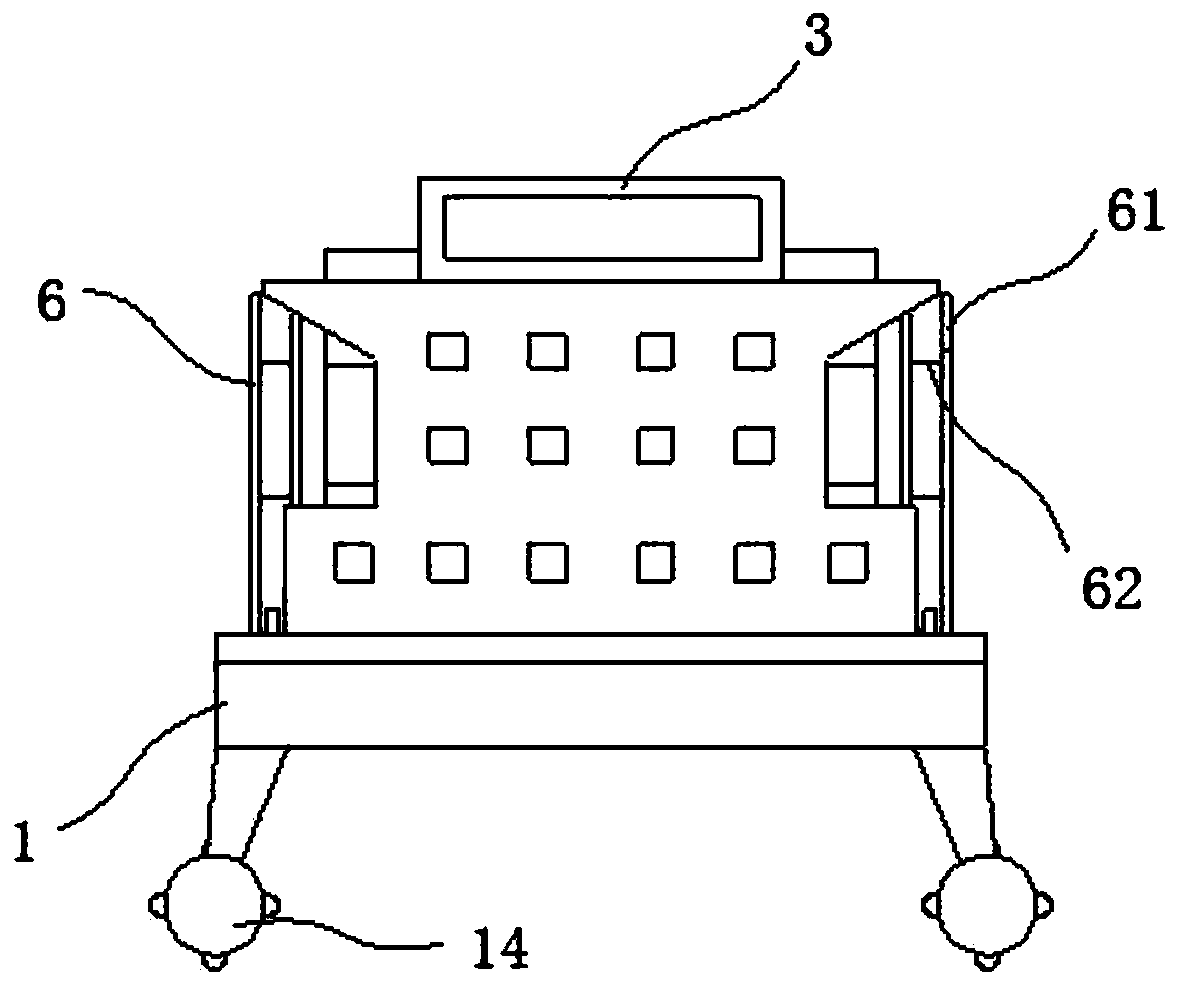

[0032] In order to make the technical means, creative features, objectives and effects of the present invention easy to understand, the following embodiments are combined with figure 1 Attached Picture 11 The technical solution provided by the present invention is specifically described, but the following content is not intended to limit the present invention.

[0033] figure 1 It is a structural diagram of an embodiment of a container ship capable of loading and unloading according to the present invention; figure 2 It is a structural diagram from a perspective of a preferred embodiment of the present invention; image 3 Is a structural diagram from another perspective of a preferred embodiment of the present invention; Figure 4 It is a structural diagram from another perspective of a preferred embodiment of the present invention. Such as figure 1 , figure 2 , image 3 as well as Figure 4 As shown, the container ship capable of loading and unloading provided by this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com