Method for preparing black alpha-Bi2O3 powder material

A powder material, -bi2o3 technology, applied in chemical instruments and methods, inorganic chemistry, bismuth compounds, etc., can solve problems such as low utilization of light waves, and achieve the effects of short synthesis cycle and simple and feasible preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] (1) Yellow α-Bi 2 o 3 Synthesis of powder materials

[0017] Put 1g of bismuth nitrate pentahydrate in a muffle furnace at 500°C for 6 hours, cool naturally and grind to obtain yellow α-Bi 2 o 3 powder material;

[0018] (2) Black α-Bi 2 o 3 Synthesis of powder materials

[0019] 0.04g of the yellow α-Bi obtained in step (1) 2 o 3 Put the powder material in a reaction vessel, add 100mL deionized water and 0.4g hydrogen peroxide, and irradiate with a mercury lamp with a power of 300W for 1 hour under the condition of magnetic stirring. Dry at 80°C for 150 minutes to obtain the target product black α-Bi 2 o 3 powder material.

Embodiment 2

[0021] (1) Yellow α-Bi 2 o 3 Synthesis of powder materials

[0022] Put 1g of bismuth nitrate pentahydrate in a muffle furnace at 500°C for 6 hours, cool naturally and grind to obtain yellow α-Bi 2 o 3 powder material;

[0023] (2) Black α-Bi 2 o 3 Synthesis of powder materials

[0024] 0.2g of the yellow α-Bi obtained in step (1) 2 o 3 Put the powder material in a reaction vessel, add 100mL deionized water and 1g hydrogen peroxide, and irradiate with a mercury lamp with a power of 300W for 1 hour under the condition of magnetic stirring. Dry at ℃ for 180 minutes to obtain the target product black α-Bi 2 o 3 powder material.

Embodiment 3

[0026] (1) Yellow α-Bi 2 o 3 Synthesis of powder materials

[0027] Put 1g of bismuth nitrate pentahydrate in a muffle furnace at 500°C for 6 hours, cool naturally and grind to obtain yellow α-Bi 2 o 3 powder material;

[0028] (2) Black α-Bi 2 o 3 Synthesis of powder materials

[0029] 0.04g of the yellow α-Bi obtained in step (1) 2 o 3 Put the powder material in a reaction vessel, add deionized water and 0.68g hydrogen peroxide, irradiate with a mercury lamp with a power of 300W for 1 hour under the condition of magnetic stirring, pour off the upper clear night after standing, and place the precipitate in a drying oven at 100 ℃ drying for 120 minutes to obtain the target product black α-Bi 2 o 3 powder material.

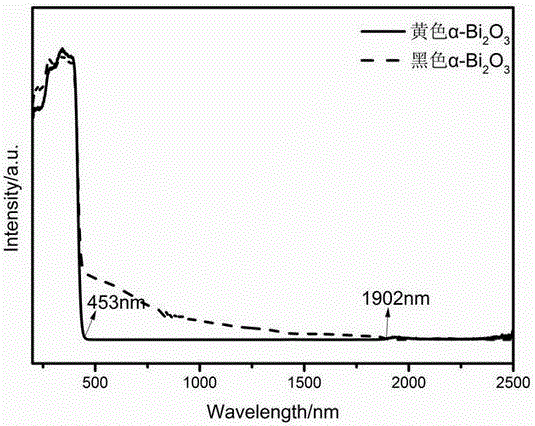

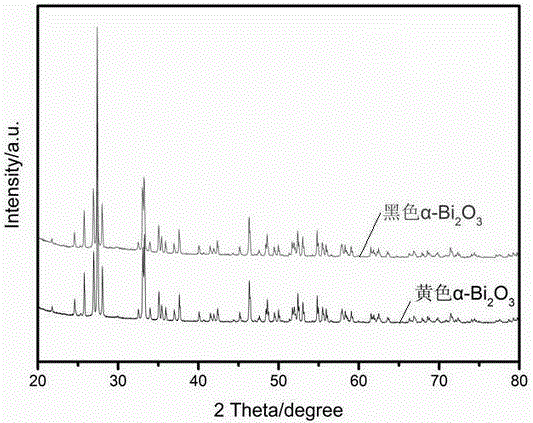

[0030] The present invention adopts a novel preparation process, in yellow α-Bi 2 o 3 Hydrogen peroxide is added to the powder material and deionized water. Under the action of hydrogen peroxide, oxygen vacancies are generated in the process of mercury...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com