Bamboo fiber reinforced composite material composition and preparation method of bamboo fiber reinforced composite material

A technology for reinforcing composite materials and reinforcing materials, which is applied to the preparation of bamboo fiber reinforced composite materials and the field of bamboo fiber reinforced composite material compositions, can solve problems such as poor environmental protection performance, and achieve the effects of environmental protection performance and good tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

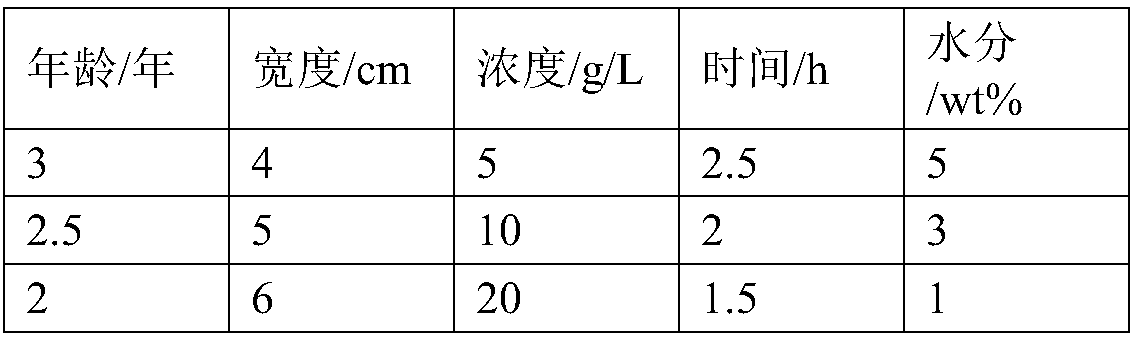

preparation example Construction

[0029] In another typical embodiment of the present application, there is also provided a method for preparing a composite material, the preparation method comprising: matrix material, reinforcing material, auxiliary material and their proportions in the composition of any one of the above composite materials Mixing to obtain a mixture; extruding and granulating the mixture to obtain a semi-finished product; injecting, extruding or molding the semi-finished product to obtain a composite material.

[0030] The above-mentioned preparation method uses the composition of the above-mentioned composite material, uses the natural product bamboo fiber and shell powder as the reinforcing material, and cooperates the reinforcing material with the thermoplastic resin of the matrix material according to the above-mentioned ratio, and passes the bamboo fiber and shell powder and the thermoplastic resin. The synergistic effect among them makes the composite material prepared by the compositi...

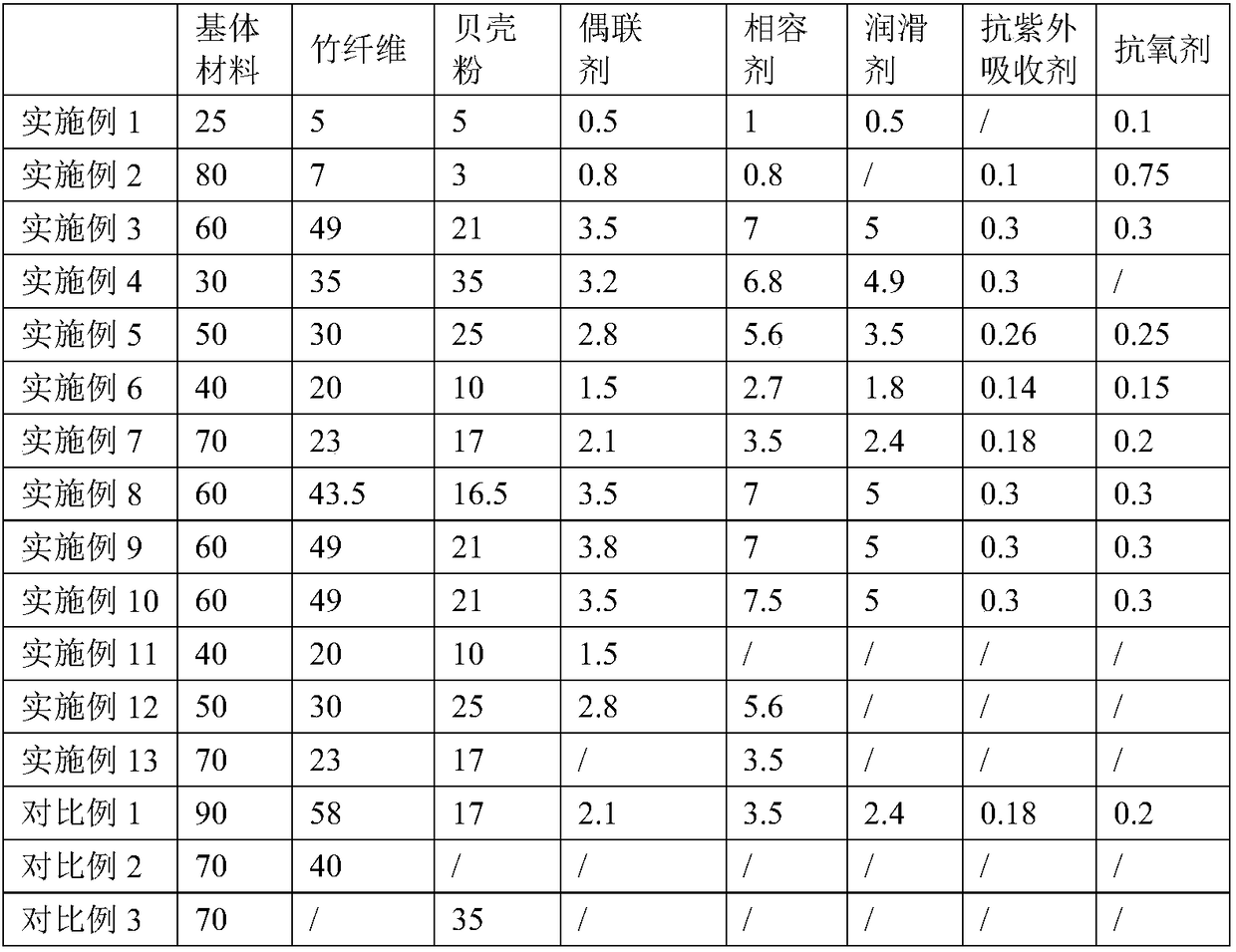

Embodiment 1

[0047] According to the raw material ratio in Table 2 and the raw materials in Table 3, the bamboo fiber reinforced composite material composition of Example 1 is formed, and the reinforcing material is first placed in a hot mixing pot at 80°C and pre-prepared at a speed of 900 rpm / min. After stirring for 1 min, add a coupling agent to the pre-stirred reinforcing material, and then stir at a speed of 1000 rpm for 3 min to obtain the first premix; add the base material and the rest of the auxiliary materials to the first premix to The rotating speed of 1200 rev / min was stirred for 5min to obtain the mixture;

[0048] The mixture is extruded and granulated at 230°C to obtain a semi-finished product;

[0049] The semi-finished product is injected, extruded or molded to obtain the bamboo fiber reinforced composite material.

Embodiment 2

[0051] According to the raw material ratio in Table 2 and the raw materials in Table 3, the bamboo fiber reinforced composite material composition of Example 2 is formed, and the reinforcing material is first placed in a hot mixing pot at 110°C and pre-prepared at a speed of 950 rpm / min. After stirring for 3 minutes, add a coupling agent to the pre-stirred reinforcing material, and then stir for 1 minute at a speed of 1200 rpm to obtain the first premix; add the matrix material and the rest of the auxiliary materials to the first premix to Stir at a speed of 1000 rpm / min for 5 min to obtain a mixture;

[0052] The mixture is extruded and granulated at 180°C to obtain a semi-finished product;

[0053] The semi-finished product is injected, extruded or molded to obtain the bamboo fiber reinforced composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com