Fire-proof, non-combustible, anti-corrosion and environment-friendly cable tray box and its production process

A cable trough box, environmental protection technology, applied in the direction of layered products, synthetic resin layered products, glass/slag layered products, etc., can solve the problems of accelerated cable aging, high production cost, inconvenient transportation and installation, etc., to achieve extended use. Longevity, simple production operation, optimized cable tray effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A cable trough box, the plate used to make the cable trough box has the following structure:

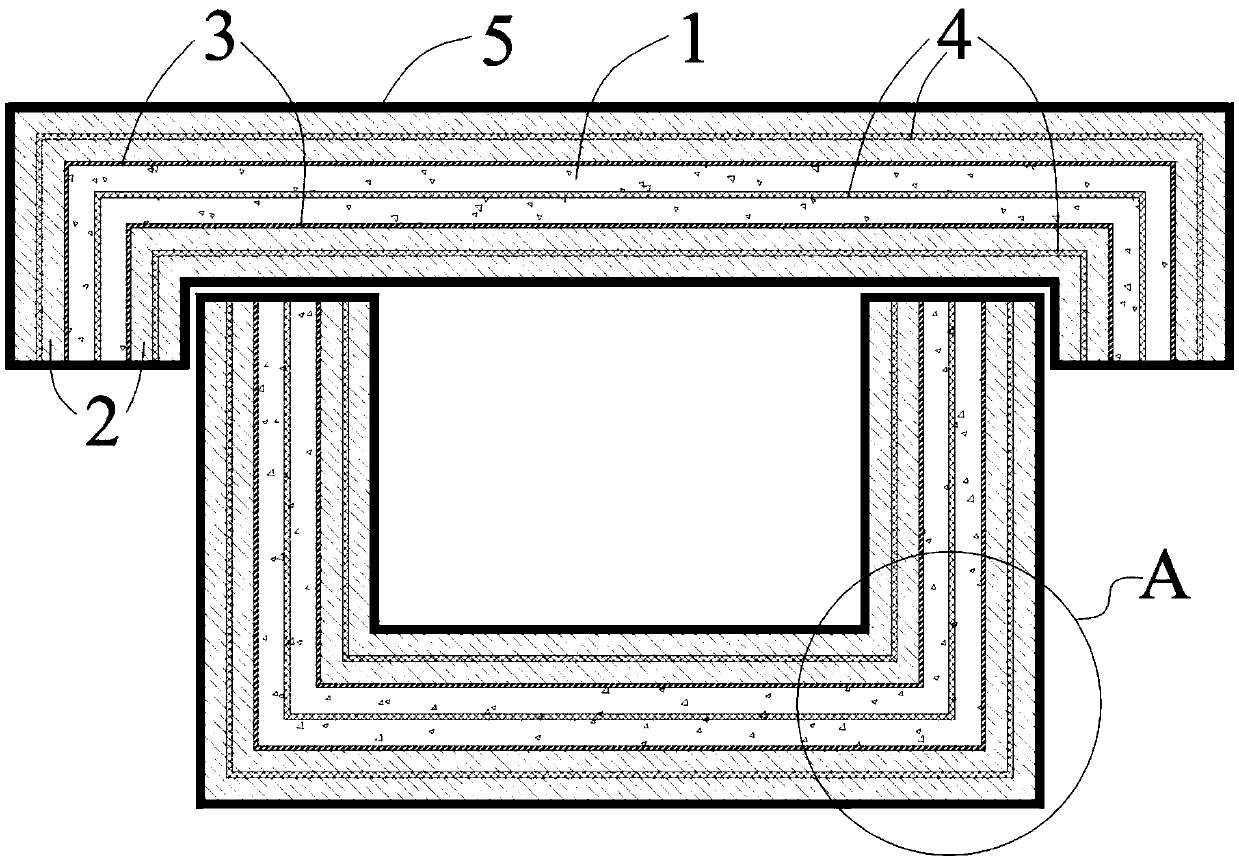

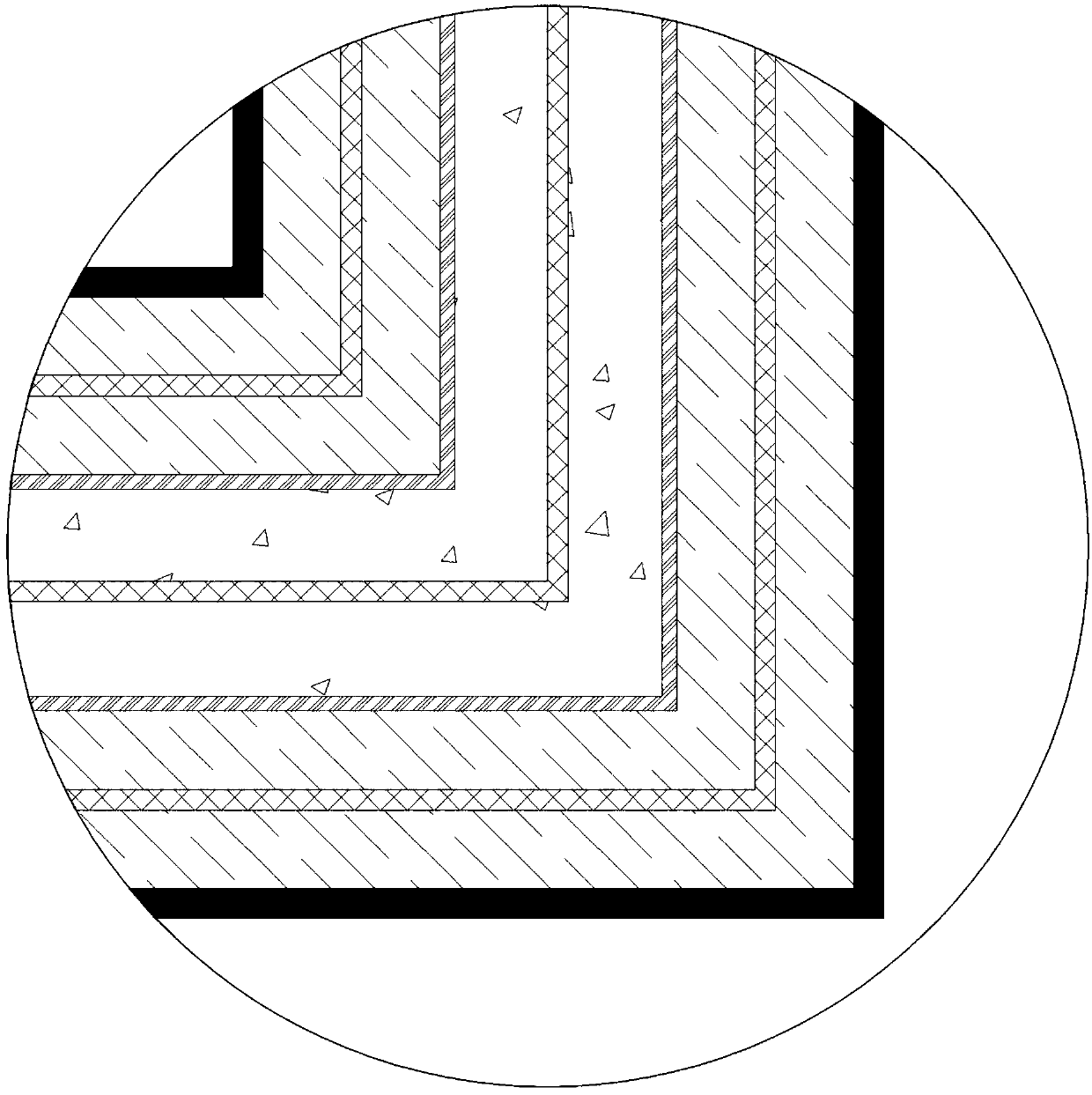

[0032] Such as figure 1 Combine figure 2 As shown, the board includes an inorganic material core 1, and a structural layer 4 is distributed inside the inorganic material core 1. The structural layer 4 is composed of alkali-free glass fiber cloth; the inorganic material core 1 is surrounded by organic materials. Layer 2, the structure layer 4 made of alkali-free glass fiber cloth is also distributed inside the organic material layer 2; there is a bonding layer 3 between the inorganic material core material and the organic material layer. The material of the bonding layer 3 is mainly composed of Acrylic waterproof paint and polyvinyl chloride waterproof paint; a gel coat layer 5 is also wrapped outside the organic material layer, and the material of the gel coat layer is gel coat resin;

[0033] The board is formed by a gel coat layer, an organic material layer, an adhesive layer, ...

Embodiment 11

[0035] This embodiment relates to the preparation of the above-mentioned cable trough box, which is carried out in the following steps:

[0036] a. Preparation of inorganic material core: Dissolve 20 parts of magnesium chloride in 30 parts of water, control the specific gravity of the magnesium chloride solution to 1.24, then add 50 parts of powdered magnesium oxide, stir and mix uniformly, and solidify to obtain a solid core that meets the strength requirements ;

[0037] b. Preparation of organic material layer: add 1 part of aluminum hydroxide powder to 1 part of liquid bisphenol A type epoxy resin, stir evenly, then add 0.3 part of T31 phenalkamine epoxy resin curing agent, mix evenly and then cure , To obtain the organic material layer solid;

[0038] c. Preparation of the bonding layer: mix 0.75 parts of acrylic waterproof coating (such as the acrylate waterproof coating of product model HCA101) with 1 part of polyvinyl chloride waterproof coating (such as the PVC waterproof c...

Embodiment 12

[0042] This embodiment relates to the preparation of the above-mentioned cable trough box, which is carried out in the following steps:

[0043] a. Preparation of inorganic material core: Dissolve 25 parts of magnesium chloride in 30 parts of water, control the specific gravity of the magnesium chloride solution to 1.26, then add 45 parts of powdered magnesium oxide, stir and mix uniformly, and solidify to obtain a solid core that meets the strength requirements body;

[0044] b. Preparation of organic material layer: add 2 parts of aluminum hydroxide powder to 2 parts of liquid bisphenol A epoxy resin, stir evenly, then add 0.4 part of T31 phenalkamine epoxy resin curing agent, and mix evenly Curing to obtain a solid organic material layer;

[0045] c. Preparation of bonding layer: mix 1 part of acrylic waterproof paint (such as acrylate waterproof paint of product model HCA101) with 1 part of polyvinyl chloride waterproof coating (such as PVC waterproof paint of product model 881)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com