A preparation method and system of phosphor copper anode for integrated circuit

An integrated circuit and phosphor copper technology, which is applied in the field of preparation of phosphor copper anodes for integrated circuits, can solve the problems of complex manufacturing process, etc., and achieve the effects of simple manufacturing process, high ductility, and high filling capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

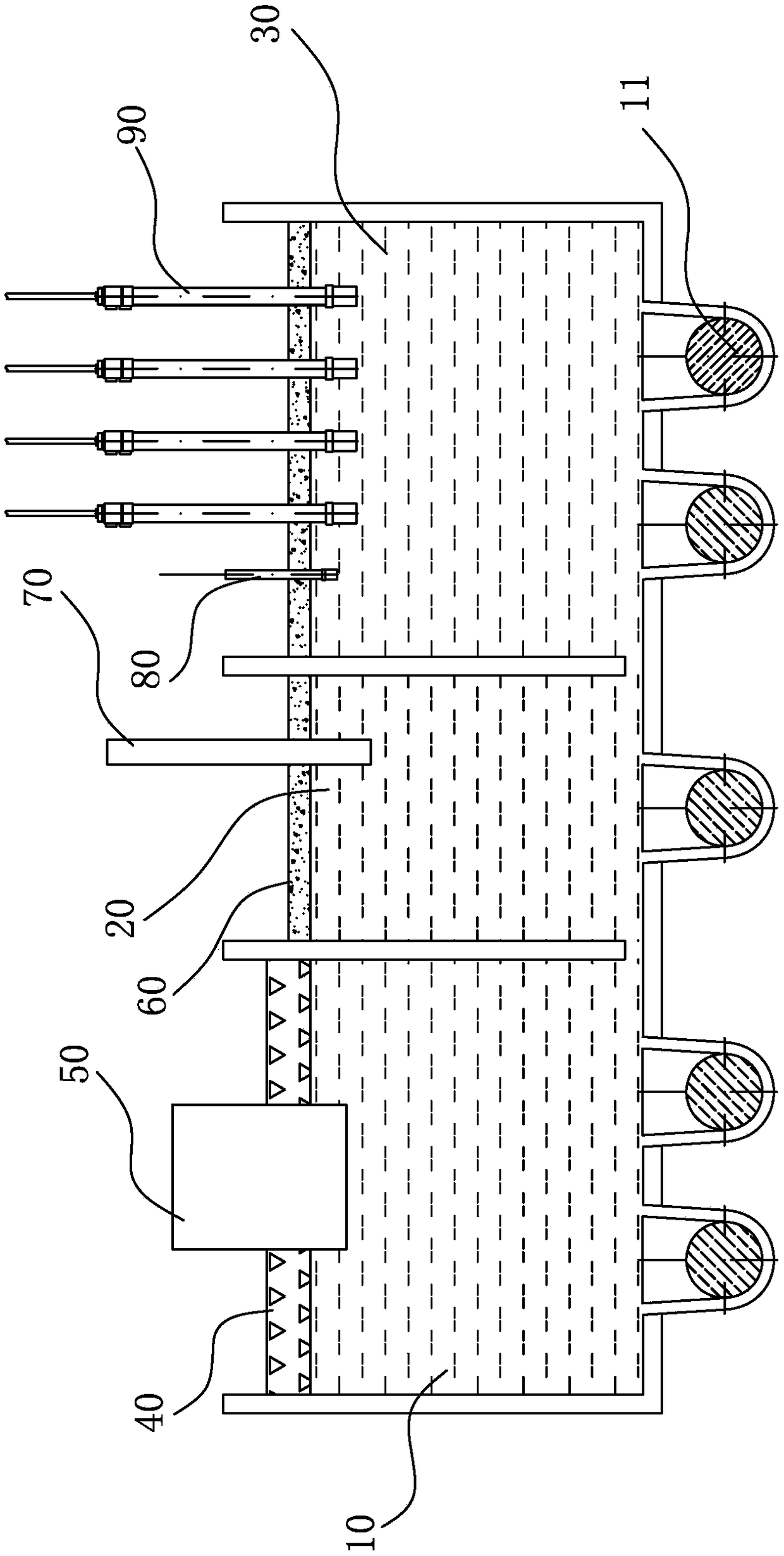

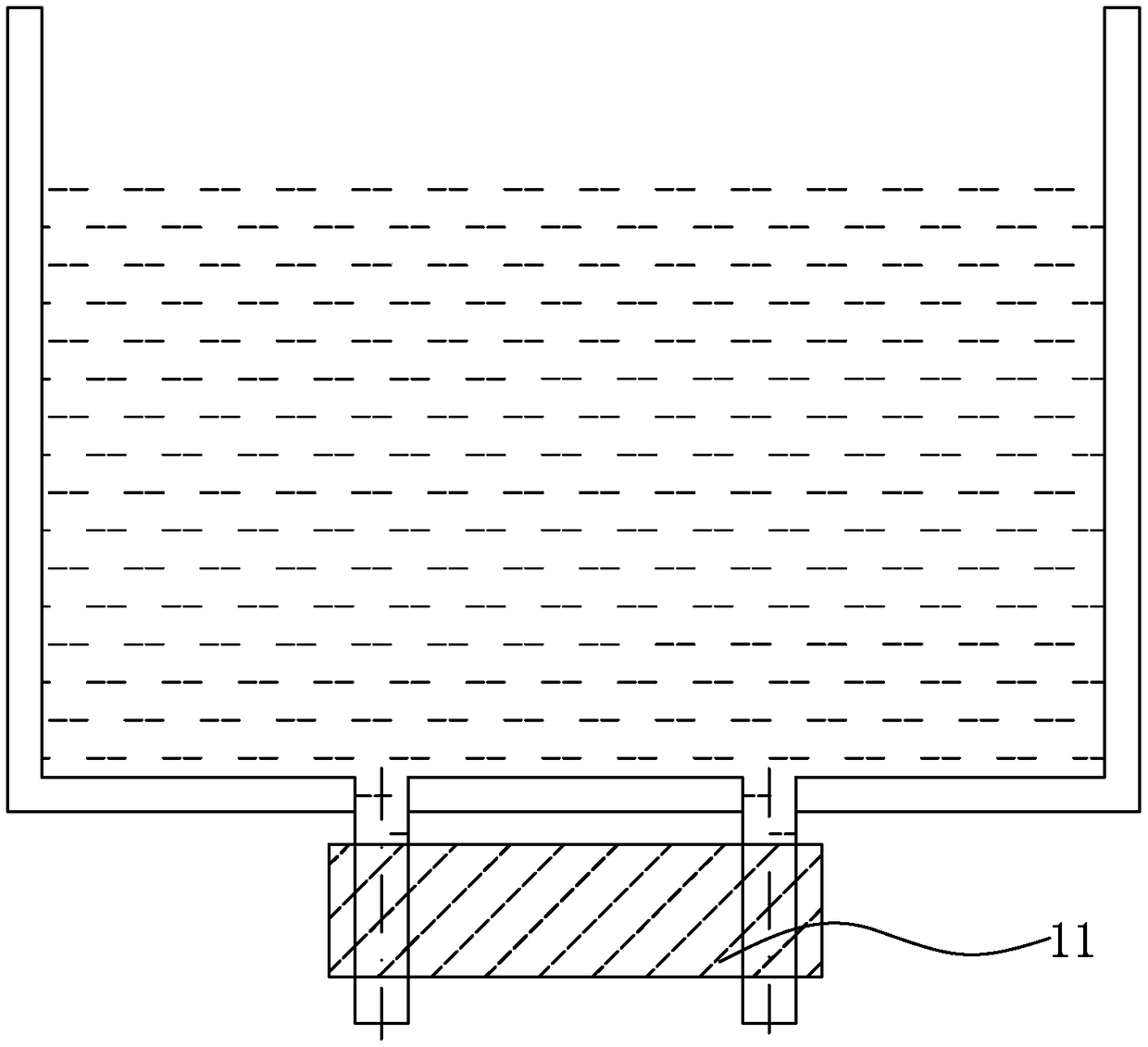

[0031] like Figure 1-7 In the specific embodiment shown, the preparation method of a phosphor copper anode for integrated circuits provided in this embodiment can be applied to the process of electroplating copper for integrated circuits, electroplating copper for high-end PCBs, and electroplating copper for high-end surface treatment, so that the manufacturing process is simple , the prepared phosphorus copper anode for integrated circuits has high filling capacity, and has higher ductility, high purity copper and small and uniform grain size.

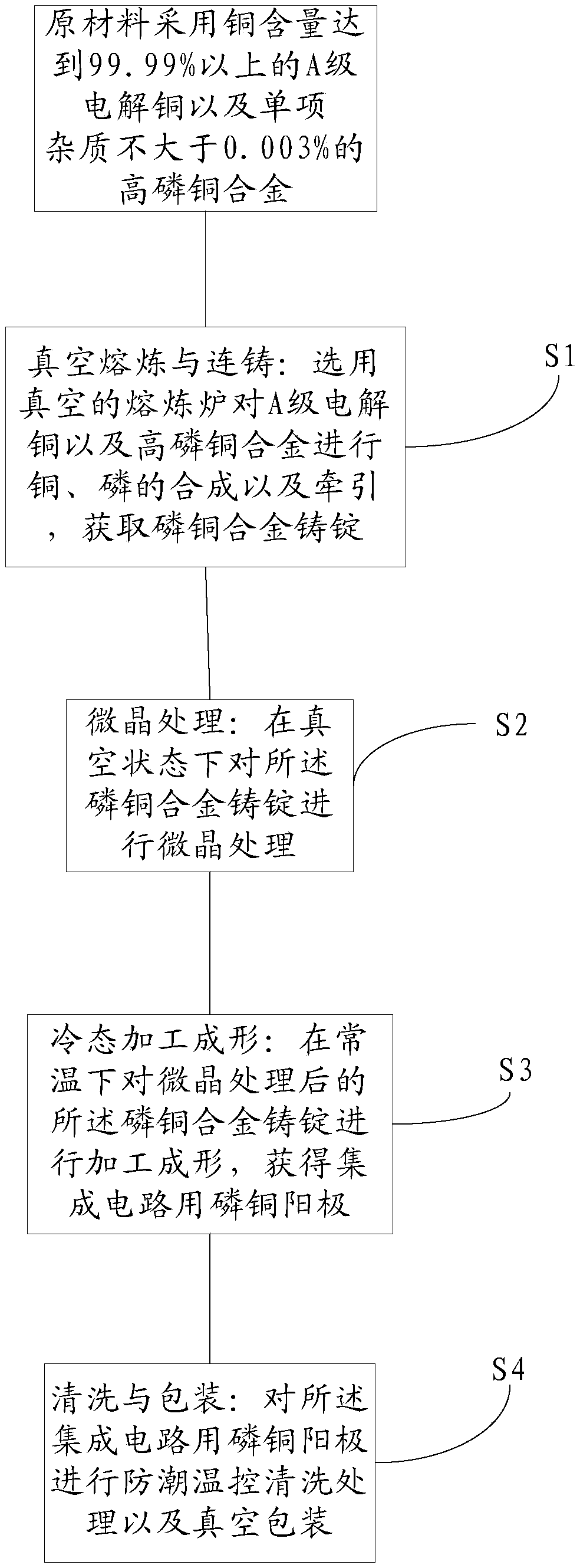

[0032] like figure 1 Shown, a kind of preparation method of phosphor copper anode for integrated circuit comprises:

[0033] The raw materials are A-grade electrolytic copper with a coppe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com