Rotary tooth

A technology of rotating seat and rotating axis, which is applied in the field of rotating gears, and can solve the problem that cutting teeth cannot use composite teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

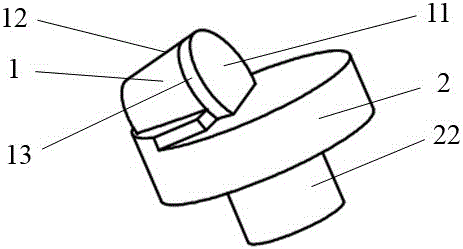

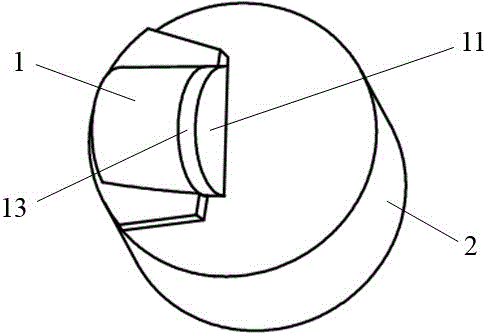

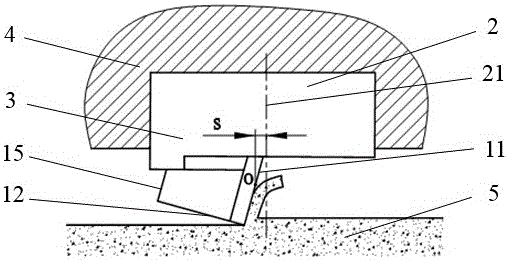

[0045] refer to Figure 1-6 As shown, a rotating tooth includes a cutting element 1 and a rotating seat 2, and the geometric center of the front cutting surface 11 of the cutting element 1 of the rotating tooth or the cutting surface 11 of the cutting element 1 of the rotating tooth is relative to the rotating seat 2 of the rotating tooth The rotation axis 21 of the cutting element 1 is offset, and the rear cutting surface 12 of the cutting element 1 of the rotating tooth or the geometric center O of the rear cutting surface 12 of the cutting element 1 is on the same side of the offset side. Alternatively, the cutting element 1 on the rotating tooth is a polycrystalline diamond composite (PDC tooth), polycrystalline diamond composite tooth, thermally stable polycrystalline diamond composite tooth, impregnated diamond tooth (block), cubic boron carbide, ceramic tooth, Or composite teeth made of polycrystalline diamond and impregnated diamond. As a further option, the cutting e...

Embodiment 2

[0047] This embodiment is basically the same as Embodiment 1, the difference is that: the drilling tool or rock-breaking tool 4 is a drill bit, the rotary teeth 3 are arranged on the cutting structure of the drill bit, and the rotary teeth 3 are formed by the rotary seat 2 and the cutting structure of the drill bit Rotationally connected, the rotating tooth 3 can rotate relative to the cutting structure on the drill bit. As an option, the rotary teeth 3 are arranged on the non-fixed cutting structure on the drill bit, such as being arranged on the cone 41 of the roller cone bit (such as Figure 5 ) or on the cone cutting structure of the composite drill bit (such as Figure 6 ). Alternatively, the rotary teeth 3 are arranged on a fixed cutting structure on the drill bit 4 (such as Figure 7 ). Further, the rotary teeth 3 are arranged on the radially inner third of the core area of the drill bit. Furthermore, the rotation axis of the rotary seat of the rotary tooth near t...

Embodiment 3

[0049] refer to Figure 8 As shown, this embodiment is basically the same as Embodiment 1, the difference is that a locking structure 7 is provided between the rotary tooth 3 and the drilling tool or rock breaking tool 4 to limit the movement of the rotary tooth 3 in the direction of the rotation axis 21 . A retaining ring structure can be arranged between the rotary tooth 3 and the drilling tool or the rock-breaking tool 4 to prevent the rotary tooth 3 from moving along the direction of the rotation axis 21 or falling off along the axis. A threaded structure can be provided between them, and the rotating tooth 3 is limited in the rotating tooth hole of the drilling tool or the rock breaking tool 4 through the nut, so as to prevent the rotating tooth 3 from moving or falling off along the direction of the rotation axis 21. As a further option, ball locking is adopted between the rotary tooth 3 and the drilling tool or the rock breaking tool 4 (such as Figure 8 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com