High-pressure fan silencer

A high-pressure fan and muffler technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems that affect normal work and study, the noise reduction effect is not obvious, and the dust is easy to block, so as to achieve obvious noise reduction effect and small resistance , the effect of not being blocked

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

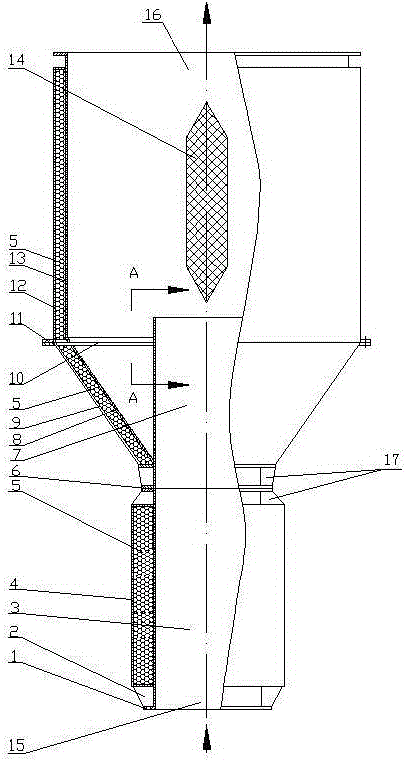

[0014] Fan muffler structure of the present invention is as figure 1 and figure 2 As shown, a high-pressure fan muffler, the inner center of the first-level sound-absorbing outer cylinder 4 is provided with a first-level sound-absorbing perforated plate inner cylinder 3, and between the first-level sound-absorbing outer cylinder 4 and the first-level sound-absorbing porous plate inner cylinder 3 is provided with sound-absorbing cotton 5 , the lower end of the first-level silencer outer cylinder 4 and the first-level silencer porous plate inner cylinder 3 is connected to the air inlet 15, and the air inlet 15 is connected to the first-level silencer outer cylinder 4 and the first-level through the inlet flange 1 and the air inlet rib plate 2 The inner cylinder 3 of the sound-absorbing porous plate; the upper part of the first-level sound-absorbing outer cylinder 4 is connected to the outer cylinder 9 of the diffuser cone, and the outer cylinder 9 of the diffuser cone is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com