Tower stay wire bending device suitable for large bending force

A bending device and high bending force technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of affecting the safety of human body and gasket line equipment, uneven force on contact parts, poor matching of connected parts, etc., to achieve accurate Dense and reliable fixation, improved safety and reliability, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the implementation manner of the present invention will be explained in detail below in conjunction with the accompanying drawings.

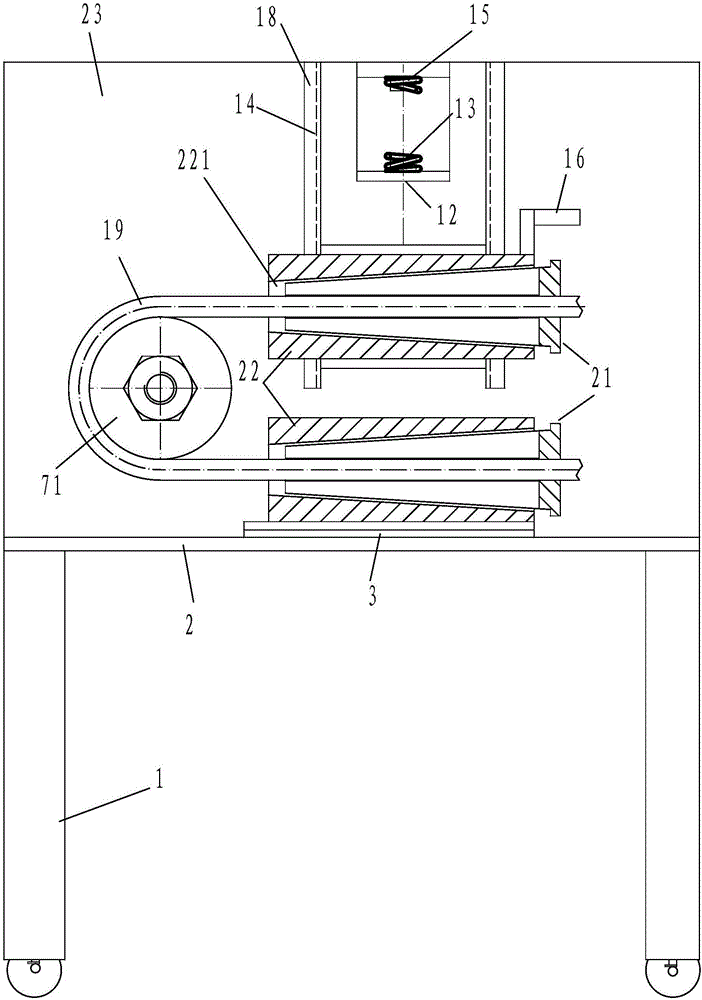

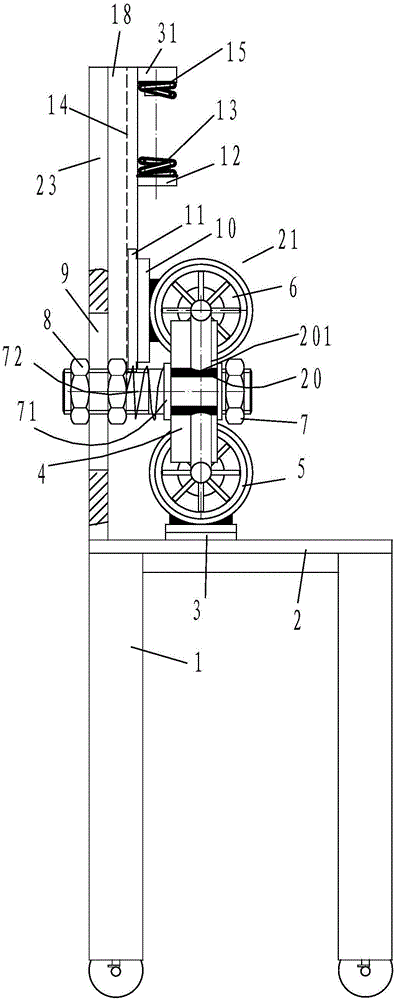

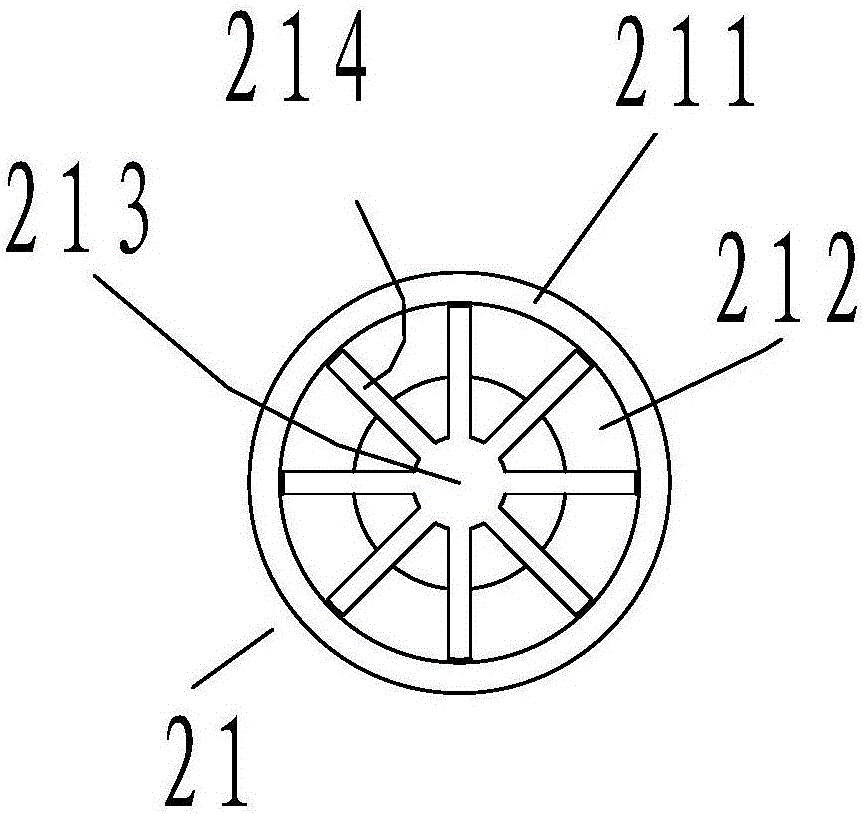

[0033] Such as Figure 1 to Figure 4 As shown, a tower rod stay wire bending device suitable for large bending force includes a connected vertical support 1 and a horizontal support 2. The horizontal support 2 is provided with a support structure under the stay wire. It is equipped with a stay wire support structure and a stay wire bending positioning structure. The stay wire bending positioning structure includes a fixed shaft 7. The support structure under the pull wire is matched, the other end of the pull wire is matched with the support structure on the pull wire. Bend the pull wire at the bending part of the pull wire into a desired arc shape. The lower part of the vertical support is provided with universal moving wheels.

[0034] The support structure on the pull wire is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com