Harmonic filtering method and harmonic filtering device for intermediate frequency furnace

A technology for harmonic filtering and intermediate frequency furnaces, which is applied in harmonic reduction devices and AC networks to reduce harmonics/ripples, etc. It can solve the problems of poor harmonic control effect and inter-harmonic pollution of intermediate frequency furnaces, and achieve continuous smoothness Adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

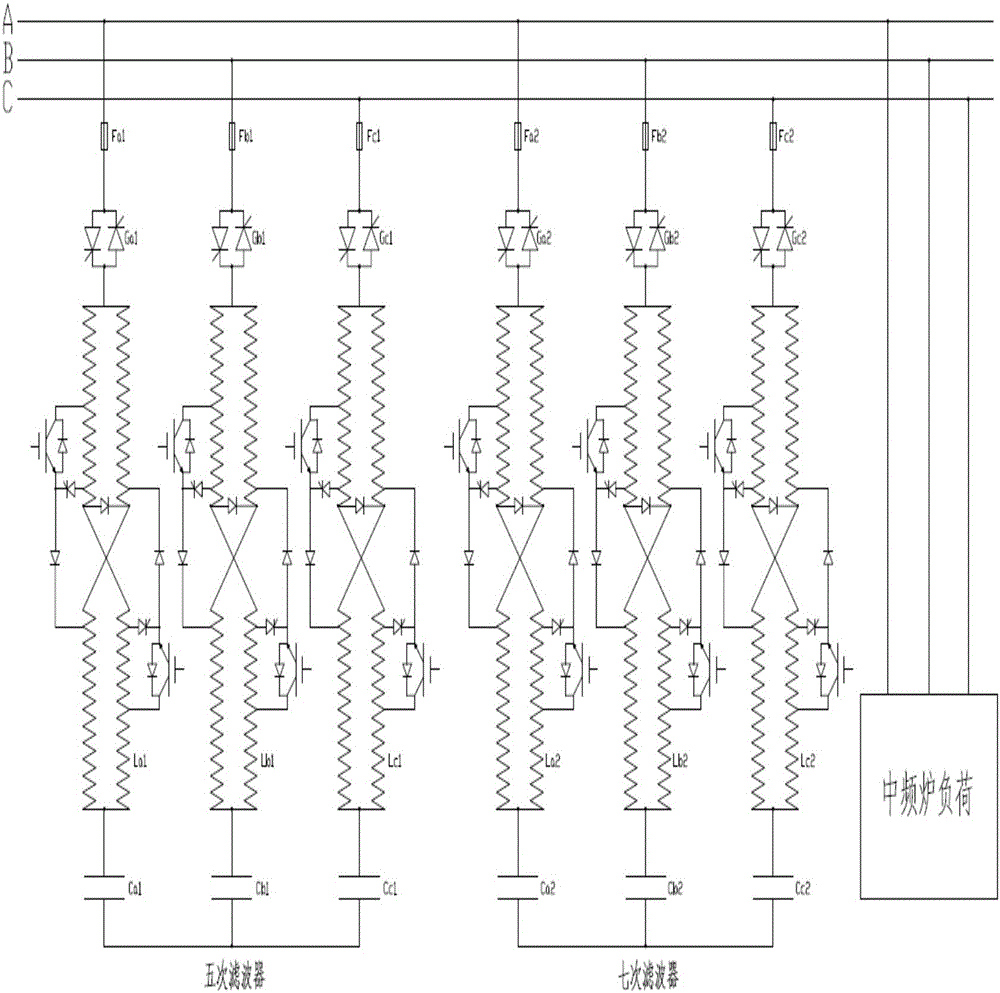

[0031] A harmonic filtering method for an intermediate frequency furnace of the present invention comprises the following steps: Step 1. Install a filter on the side of the power line, and set three filtering channels of 5, 7, 11, and 13 times in the filter, and install a magnetic force filter on each filtering channel. Adjustable magnetron reactor;

[0032] Step 2. Judging the number of rectification pulses of the intermediate frequency furnace, and selecting the corresponding corresponding filter according to the judgment result;

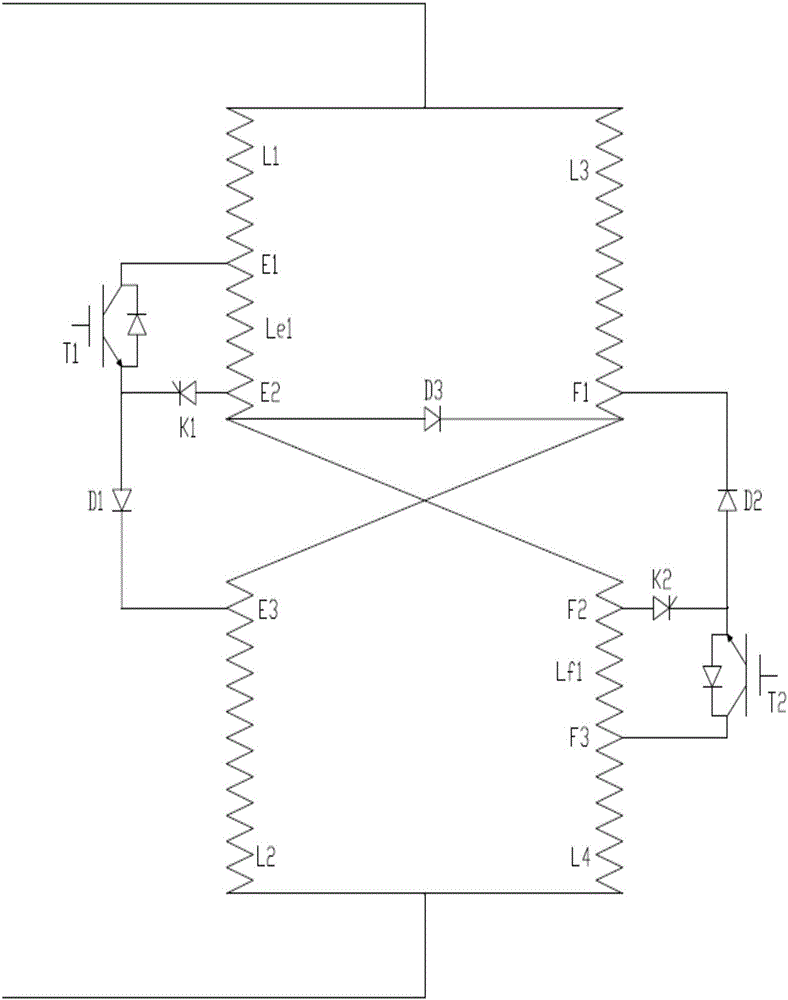

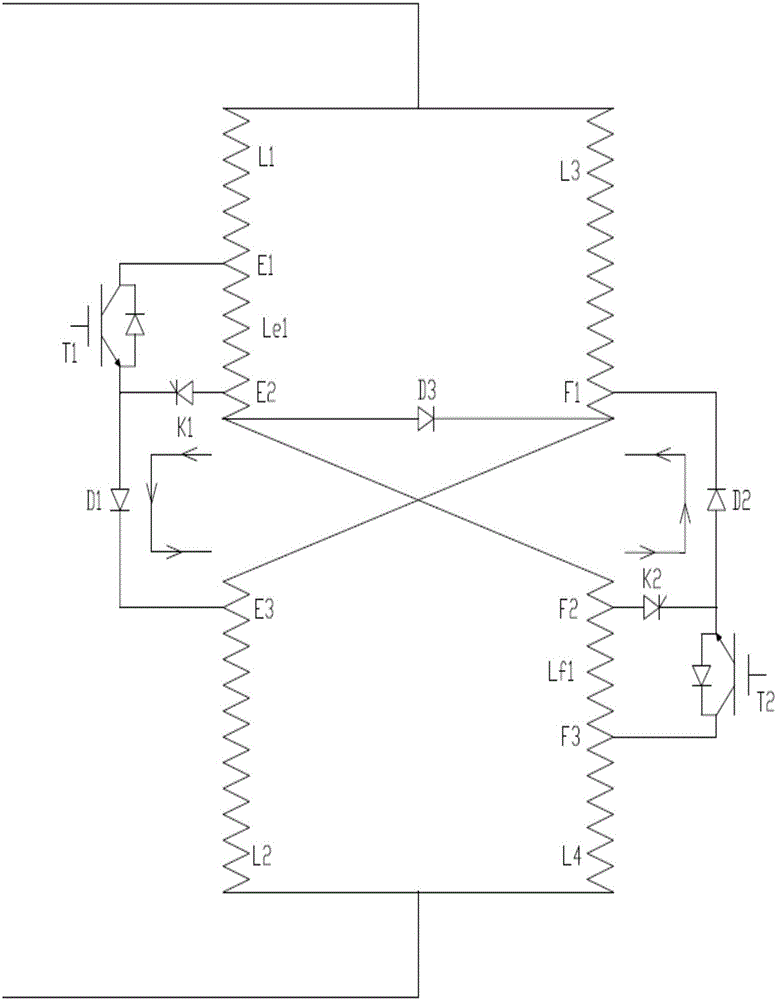

[0033] Step 3. Detect the harmonic frequency of the intermediate frequency furnace load, analyze and calculate the detected harmonic frequency, and obtain the estimated value of the filter reactance;

[0034] Step 4, detecting the actual value of the filter reactance;

[0035] Step 5. Compare the estimated value of the filter reactance w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com