Load and liquid level coordinative control system of multiple stages of pulp preheaters in high-pressure acid leaching and feeding process

A technology of coordinating control system and preheater, applied in the field of control, can solve problems such as damage to the feed pump, increase of low temperature preheater, instability, etc., and achieve the effect of simple and reliable system structure, continuous and stable adjustment, and stable control effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

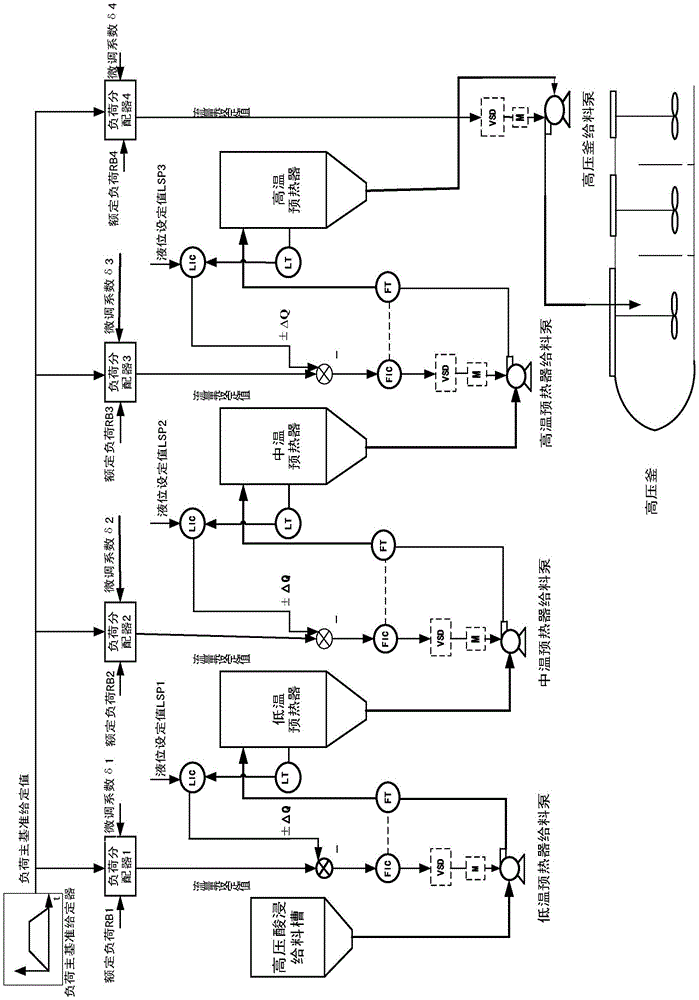

[0027] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

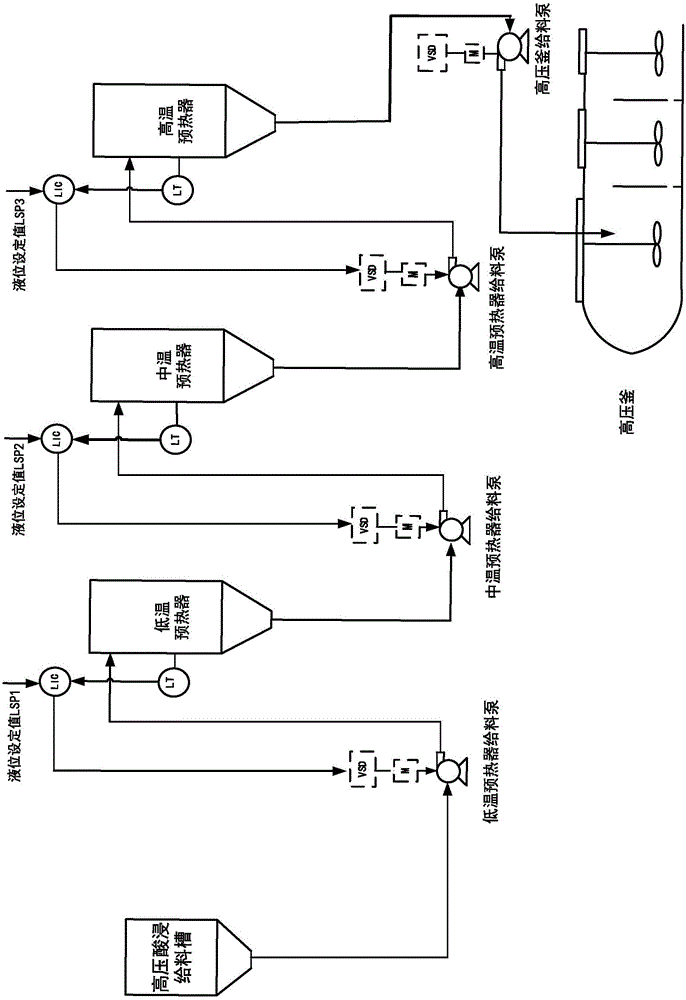

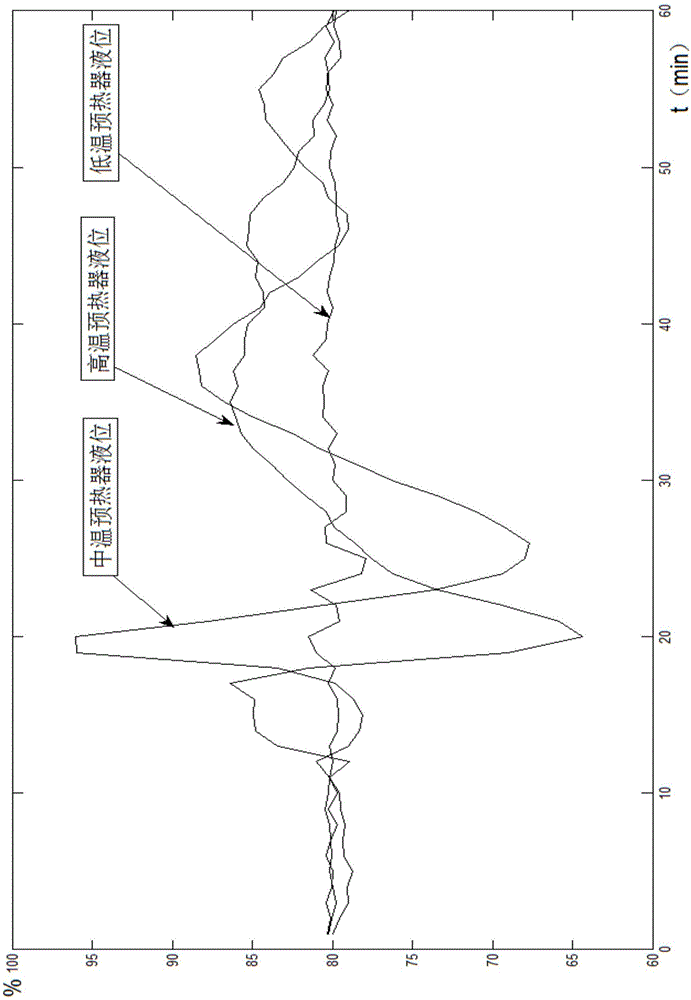

[0028] By the content of the background technology and figure 1 Obviously, the root cause of the fluctuation of the preheater liquid level in the high pressure acid leaching process is the cumulative effect of the difference between the preheater feed volume and discharge volume. Preheater at a certain time:

[0029] 1. If the feed volume < discharge volume, its liquid level will drop;

[0030] 2. If the feed volume > discharge volume, its liquid level will rise;

[0031] 3. If the feed amount = discharge amount, the liquid level remains unchanged at the original position.

[0032] Moreover, the feed pump of the preheater at this stage happens to be the discharge pump of the upper stage preheater. When adjusting the load, first adjust the flow rate of the downstream autoclave feed pump (that is, change the discharge volume of the high temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com