Control method of frequency converter and control device

A control method and control device technology, applied in the field of frequency converters, can solve problems such as frequency converter overcurrent and equipment shutdown, and achieve the effects of preventing circuit failures, reducing the number of shutdowns, and reducing output current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

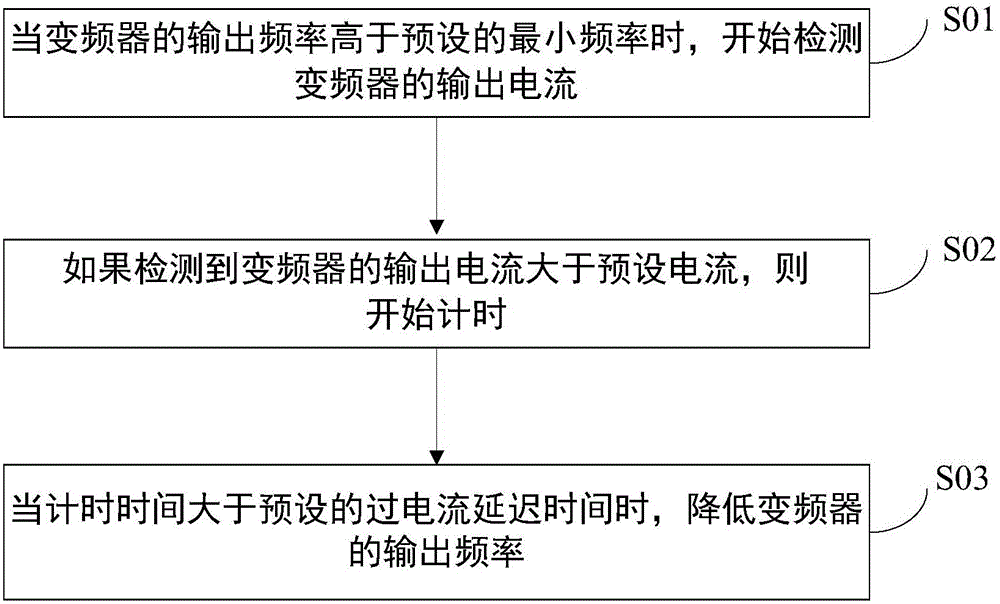

[0035] In order to solve the above problems, Embodiment 1 of the present invention provides a control method of a frequency converter, the steps are as follows figure 2 shown, including the following steps:

[0036] Step S01, when the output frequency of the frequency converter is higher than the preset minimum frequency, start to detect the output current of the frequency converter;

[0037] Step S02, if it is detected that the output current of the frequency converter is greater than the preset current, start timing;

[0038] Step S03, when the timing time is greater than the preset overcurrent delay time, reduce the output frequency of the frequency converter.

[0039] According to the size of the output current of the inverter, reduce the output frequency of the inverter to reduce the slip between the inverter and the motor. After the slip of the motor is reduced, the output current of the inverter will also decrease to prevent overcurrent faults.

[0040] It should be ...

Embodiment approach

[0047] The relevant parameters involved in the control process, the corresponding set values and the description of the setting range are shown in Table 1:

[0048]

[0049] Table I

[0050] The parameter AP-1 is used to indicate the selection of the overcurrent prevention function. When AP-1 is set to 1, the overcurrent prevention function is enabled; when AP-1 is set to 0, the overcurrent prevention function is not enabled. When the output frequency of the inverter is 60Hz higher than the minimum frequency for overcurrent prevention set by AP-2, the overcurrent prevention function starts to act, that is, when the output frequency of the inverter is higher than the minimum frequency for overcurrent prevention set by AP-2 , start to detect the output current of the inverter, and judge whether the output current of the inverter is greater than the preset current, and also judge whether the current delay time is satisfied.

[0051] Parameter AP-3 is the delay time for prev...

Embodiment 2

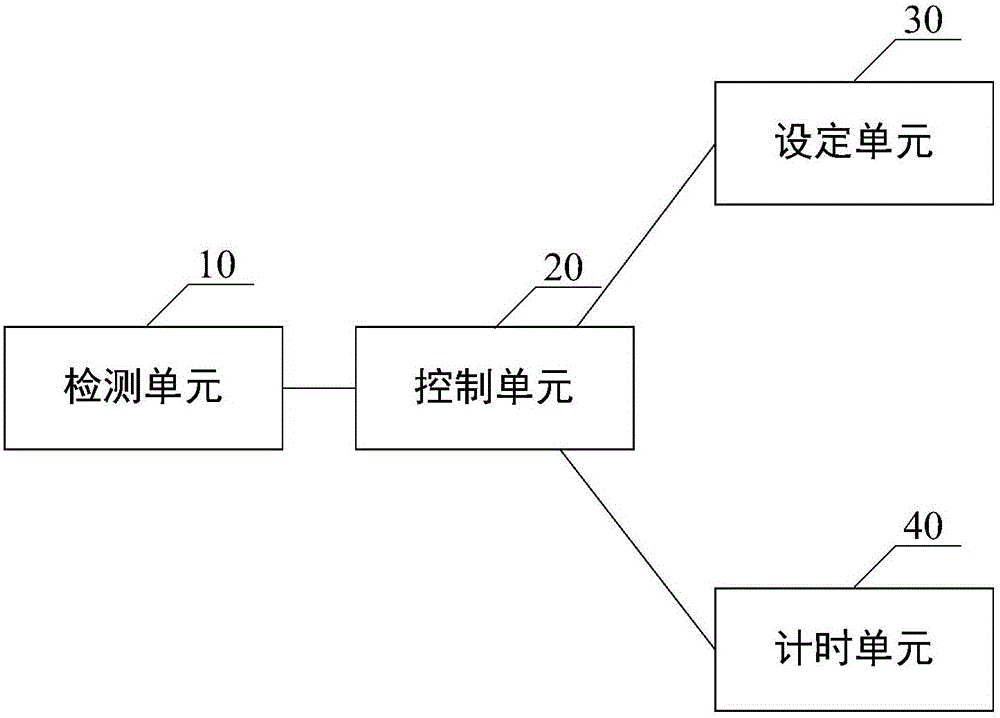

[0055] Embodiment 2 of the present invention also provides a control device for a frequency converter, the schematic diagram of which is shown in image 3 shown, including:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com