Harvesting platform of peanut combine harvester

A technology of combine harvester and harvesting table, which is applied to excavator harvesters, harvesters, agricultural machinery and implements, etc., can solve the problems of independent lifting, limited adaptability, uneven ridge spacing, etc., to achieve stable support and work. Reliable, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

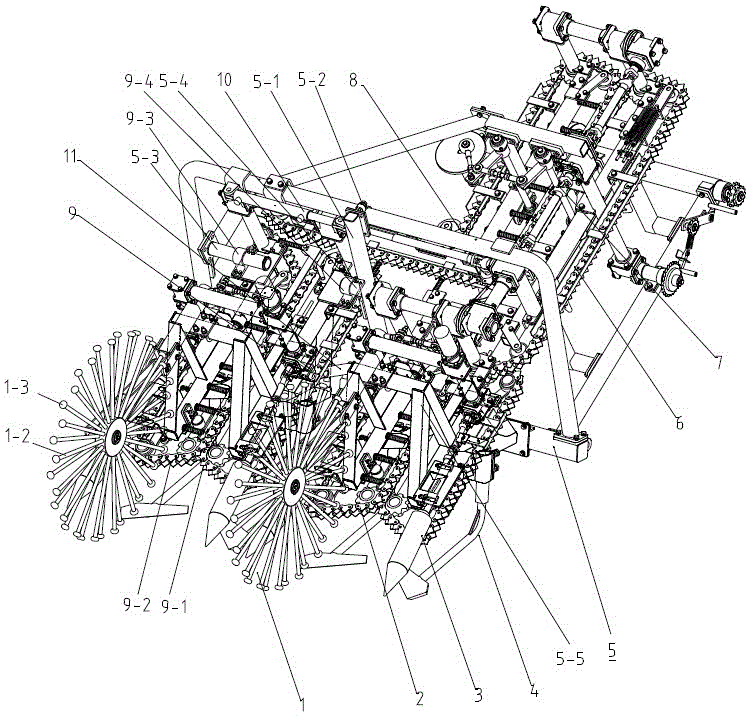

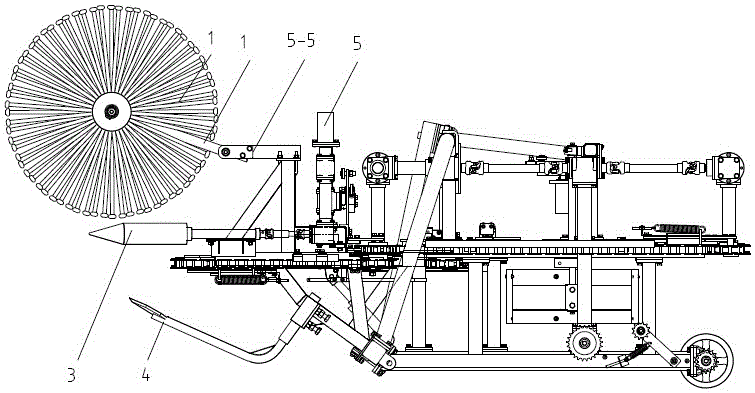

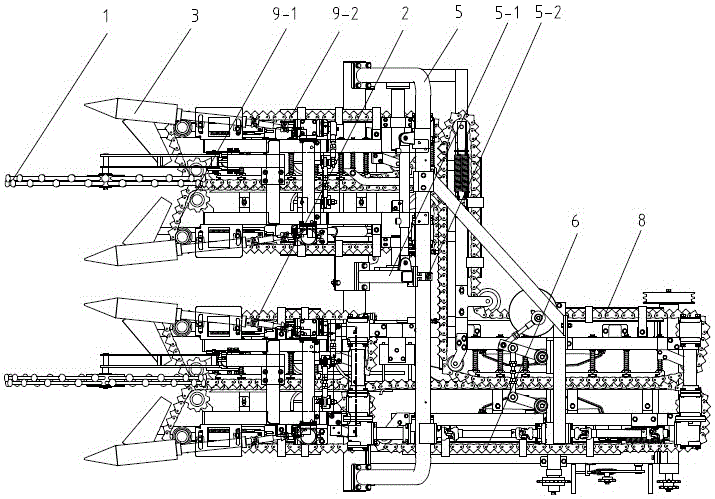

[0015] The harvesting platform of the peanut combine harvester of the present embodiment is as figure 1 , figure 2 with image 3 As shown, the harvesting platform 5 has a rectangular outer frame, and the upper and lower beam middle parts of the rectangular outer frame can lock the upper and lower ends of the vertical support 5-1 respectively through the sleeve pipe 5-2 that is matched to form a movable frame. Bit vertical support structure. The left side of the harvesting platform 5 is provided with a first clamping conveying device composed of two conveying chains 2 inside and outside, and a left middle conveying chain 6 extending longitudinally to the middle of the harvester is installed on the outside of the rear end of the first clamping conveying device. Transmission system 7 is similar to the prior art, so it will not be described in detail. The rear section of the left middle conveying chain 6 and the longitudinal section of the L-shaped conveying chain 8 constitute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com