Oil-draining and nitrogen-injecting fire extinguishing device comprising double oil draining systems

An oil discharge system, oil discharge and nitrogen injection technology, applied in fire rescue, etc., can solve problems such as inability to guarantee, inconvenient management and maintenance, and large safety hazards, achieve reasonable structural design, solve pressure detection and pipeline oil leakage , The effect of preventing tripping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

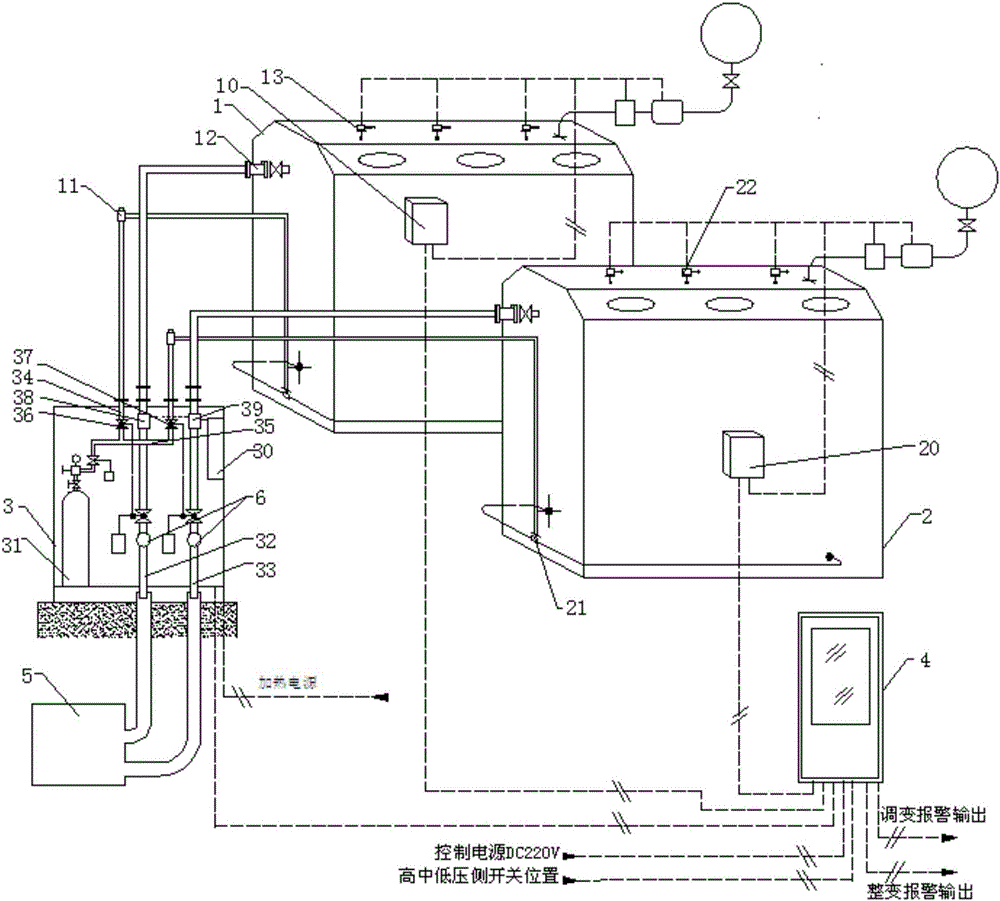

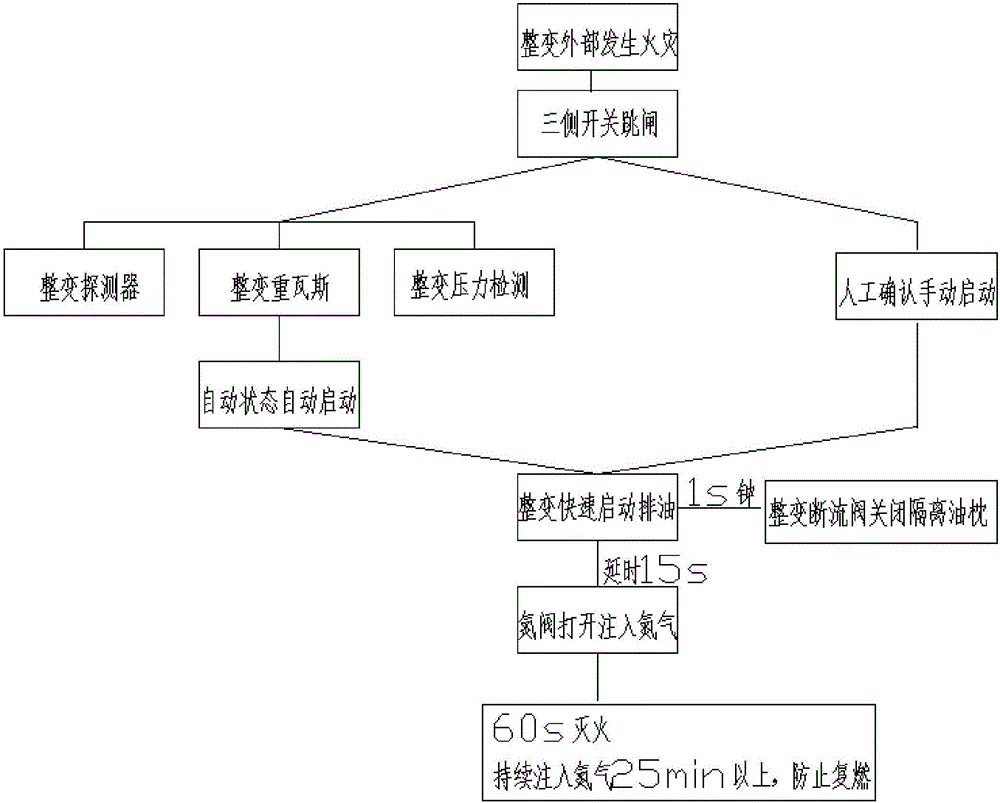

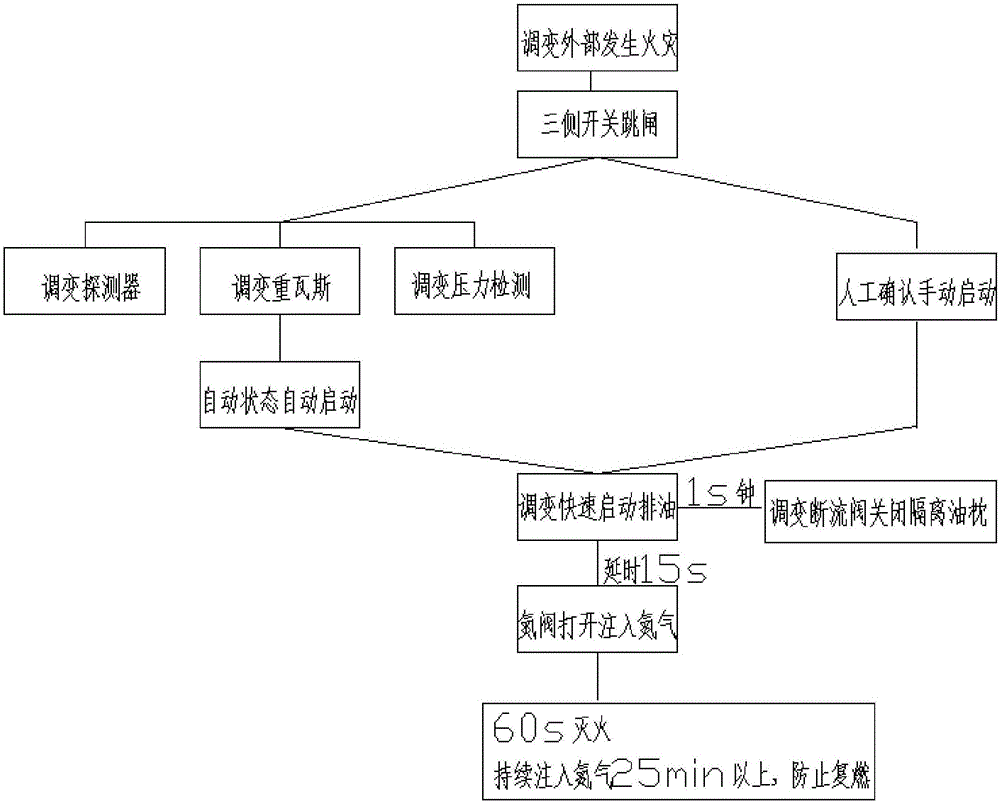

[0018] as attached figure 1 and 4 Shown is an oil discharge and nitrogen injection fire extinguishing device with a double oil discharge system, the device includes: a fire cabinet 3, a first transformer 1, a second transformer 2, a control cabinet 4 and an emergency oil pool 5, and the fire cabinet 3 is set There are a terminal box 30, a nitrogen cylinder 31, a first oil discharge pipeline 32, a second oil discharge pipeline 33, a first nitrogen injection pipe 34 and a second nitrogen injection pipe 35 arranged on the outlet pipeline of the nitrogen cylinder 31, and the first nitrogen injection pipe The pipe 34 and the second nitrogen injection pipe 35 are respectively provided with a first linkage distribution valve 36 and a second linkage distribution valve 37, and the first oil discharge pipeline 32 and the second oil discharge pipeline 33 are respectively provided with a first pressure detection 38, the first oil discharge valve and the second pressure detector 39, the s...

Embodiment 2

[0020] This embodiment is a further description of the technical solution of the present invention on the basis of the first embodiment above, wherein, the first nitrogen injection pipe 34 and the second nitrogen injection pipe 35 are arranged in parallel, and the first nitrogen injection pipe 34 and the second nitrogen injection pipe 34 are arranged in parallel. The nitrogen injection pipe 35 is provided with a nitrogen pipe exhaust assembly 11 and a nitrogen gas shunt assembly 21 (the nitrogen is divided into two paths to be connected respectively from the front and the rear of the transformer, and the inlet is provided with a nitrogen injection interface valve); the first oil discharge pipe The upper part of the road 32 and the upper part of the second oil discharge pipeline 33 communicate with the first transformer 1 and the second transformer 2 through the oil discharge interface valve and the flange respectively, and the upper part of the first oil discharge pipeline 32 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com